Product Information

-

- High melting point /

hard material

powder

-

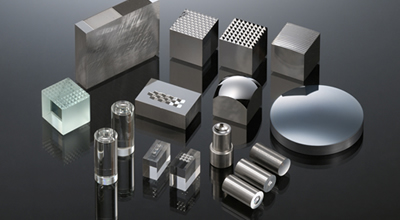

- Cemented carbide

-

- Tungsten /

molybdenum

products

-

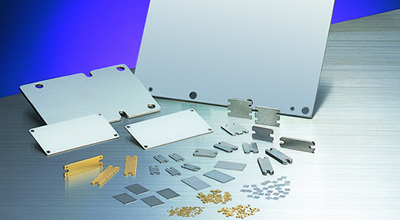

- High performance

heatspreaders

-

- Diamond /

CBN tools

About A.L.M.T. Corp.

- Our Strengths

- A.L.M.T. Corp. is the preferred choice in a wide variety of fields and applications. Here are some of our strengths.

Technical Information

- Tungsten

- Tungsten has high melting point and high electric resistance. In this section, we'd like to introduce the characteristics, manufacturing process and applications.

- Tungsten carbide

- What is tungsten carbide? We'd like to explain the characteristics, manufacturing process and applications.

- Cemented carbide

- In this section, we'd like to introduce the various kinds of cemented carbide, also explain the characteristics and manufacturing process.

- Molybdenum

- Molybdenum has high melting point and is easier to process. In this section, we'd like to introduce characteristics, manufacturing process and applications of molybdenum.

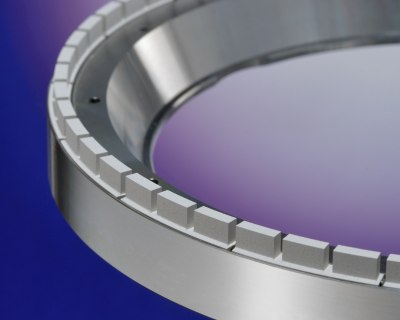

- Heatspreader

- Our heatspreaders are used in various fields. In this section, we'd like to show the characteristics, manufacturing process and applications.

- diamond / CBN tools

- In this section, we'd like to explain the basic information of diamond / CBN tools, including specification and characteristics.

R&D/Service

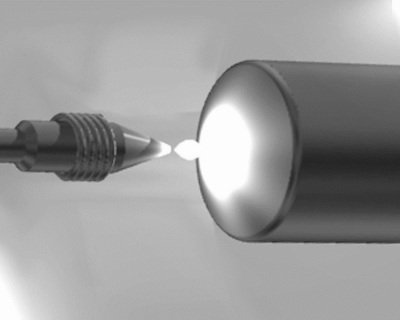

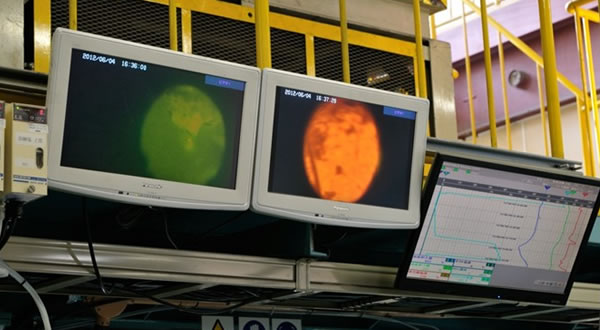

- Next generation

heatspreaders

- Technology

of recycling tungsten

- Our proprietary

molybdenum materials