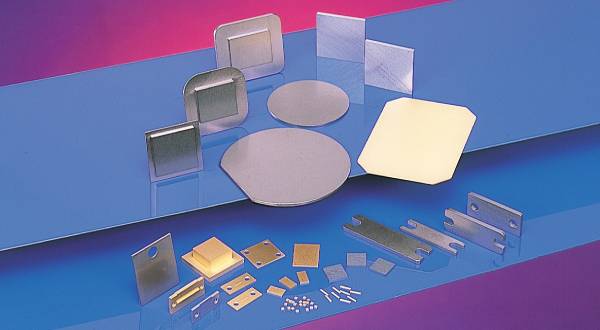

Heatspreader (heat dissipation plate) by Applications

Heatspreaders for wireless communications

Contributing to High-speed, High-capacity for Mobile Networks

With the high-speed and high-capacity of communications, and the miniaturization of devices, the amount of heat generated from semiconductors for wireless communications increased. Base stations (antennas) of 5G, which are at the start line of global popularization, are equipped with a number of GaN (gallium nitride) chips, which are compound semiconductors. Compared to the conventional silicon (Si) semiconductors, these semiconductors are smaller and have higher performance. However, because of their high density of heat generation (amount of heat generation per unit volume), efficient heat dissipation methods are indispensable to ensure the reliability of communications networks. In addition to Si semiconductors, A.L.M.T. Corp. offers various heatspreaders with high thermal conductivity and low thermal expansion, which are suitable for GaN semiconductors. And, the heat dissipation plates contribute to the next-generation mobile communications networks.

| Applications | Wireless communications, Cell base stations, Aircraft, Ships, Artificial satellites, etc. |

|---|

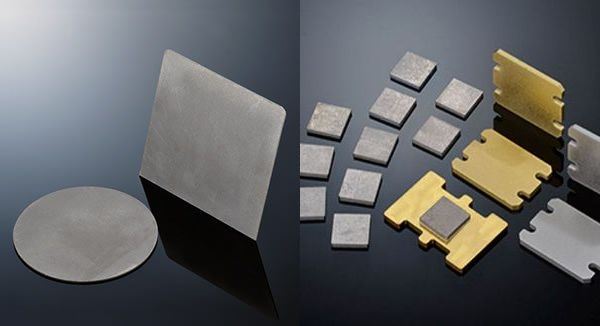

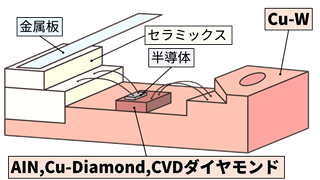

Cu-W (Copper-Tungsten)

-

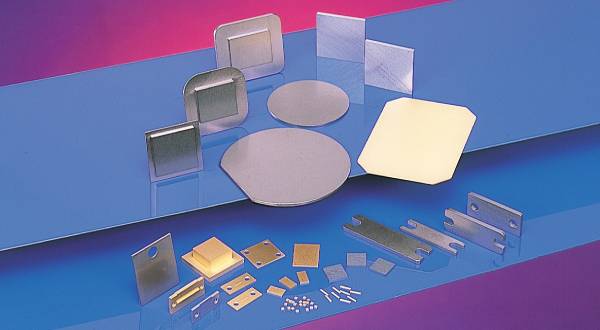

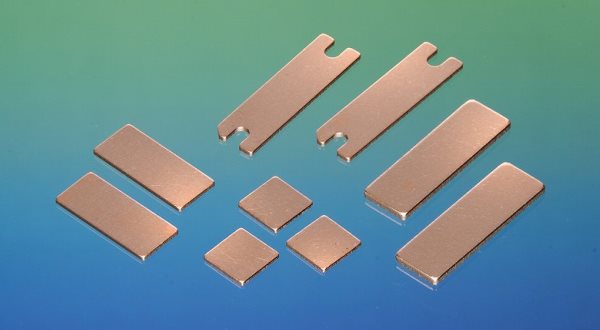

This composite material combines the high thermal conductivity characteristics of copper (Cu) with the low thermal expansion characteristics of tungsten (W), allowing the composition to be adjusted to a suitable coefficient of thermal expansion for the surrounding material. It is also excellent in machinability, and is widely used as a part for wireless communication packages, which are small and complex-shaped.

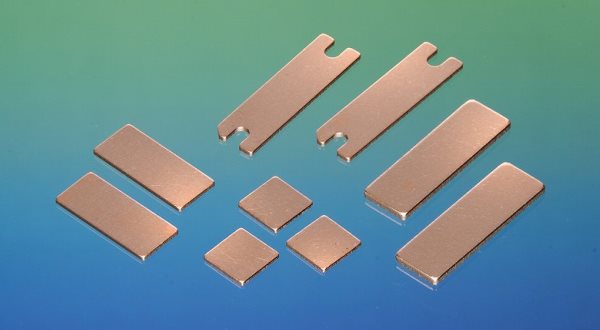

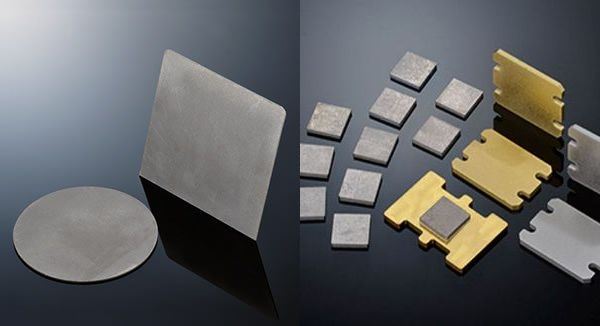

Cu-Mo (Copper-Molybdenum)

-

This is a composite material of copper (Cu), a high thermal conductivity metal, and molybdenum, a low thermal expansion metal. Its composition can be adjusted to have better coefficient of thermal expansion for the surrounding material. Since it is suitable for mass production with rolling and stamping process, it is possible to provide simple-shaped heatspreaders in large quantities at reasonable prices.

Ag-Diamond (Silver-Diamond)

-

Silver has the highest thermal conductivity of metals. Diamond has the highest thermal conductivity of any natural material. Alloying them with our technology, we have achieved heatspreaders with thermal conductivity of over 600 W/ (m・K). We can produce materials larger than conventional diamond-based materials, making them ideal for high-output devices for aerospace applications.

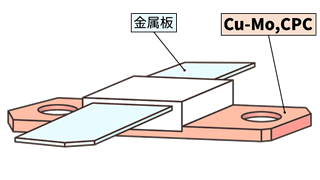

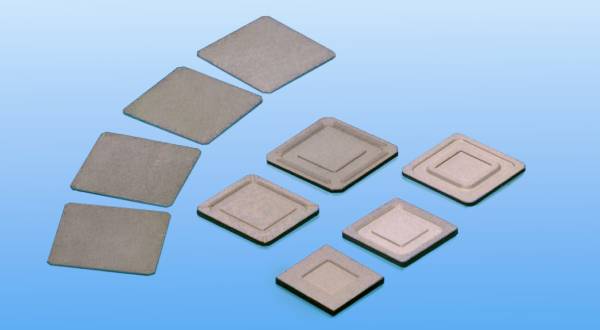

CPC™ (Copper, Copper-Molybdenum, Copper)

-

This is a three-layered composite with Cu-Mo sandwiched between pure coppers (Cu). The thermal conductivity and coefficient of thermal expansion are variable by adjusting the composition of Cu-Mo core material and the laminate ratio of Cu. In addition, since its surface is Cu, it is excellent in initial thermal dissipation. Moreover, its mass-productivity is equivalent to Cu-Mo materials.

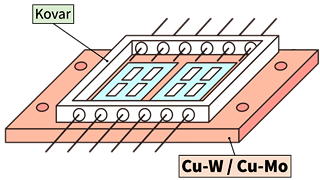

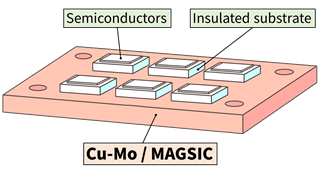

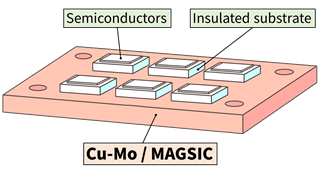

Package Example

Plastic Package

This package is used for devices of base stations that are compact and low-power.

They cover mobile phone networks densely in urban areas.

Cu-Mo (CPC) materials, which have a coefficient of thermal expansion close to semiconducting materials, are suitable for that use.

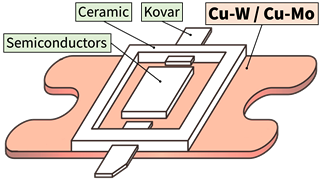

Ceramic Package

This package is used for devices of base stations with high output and covering a wide range of mobile phone networks.

Cu-Mo (CPC) and Cu-W, with a coefficient of thermal expansion close to ceramic housings, are suitable.

Metal Package for Circuit Board

It is used in applications requiring high output and reliability, such as aerospace applications.

In addition to Cu-W and Cu-Mo with a close coefficient of thermal expansion to metallic housings such as Kovar, Ag-Diamond is used in the high-end area.

Heatspreaders for optical communications

Contributing to High-speed, High-capacity for Optical Communications

Fiber-optic networks covering the entire world, from the bottom of the sea to the land, have supported the high-speed and high-capacity of the Internet. For data centers that are being newly installed in various places, optical communications are still used to connect high-performance servers. Since laser diodes that oscillate optical signals become hot, the heat dissipation plate (submount) is mounted directly below them. Our heatspreaders have a wide variety of thermal expansion coefficients, and also have good machinability suitable for complex and high-precision packaging.

| Applications | Optical communications trunk networks, FTTx systems, Data centers, in-vehicle LAN, etc. |

|---|

Cu-W (Copper-Tungsten)

-

This composite material combines the high thermal conductivity characteristics of copper (Cu), with the low thermal expansion characteristics of tungsten (W), allowing the composition to be adjusted to suitable coefficient of thermal expansion for the surrounding materials. It is also excellent in machinability, and is widely used as a part for optical communication packages, many of which are small and complex-shaped.

Cu-Mo (Copper-Molybdenum)

-

This is a composite material of copper (Cu), a high thermal conductivity metal, and molybdenum, a low thermal expansion metal. Its composition can be adjusted to have better coefficient of thermal expansion for the surrounding material. Since it is suitable for mass production with rolling and stamping process, it is possible to provide simple-shaped heatspreaders in large quantities at reasonable prices.

Cu-Diamond (Copper-Diamond)

-

This is a composite material of copper (Cu), a high thermal conductivity metal, and diamond, which has the highest thermal conductivity of any natural material. While having a coefficient of thermal expansion close to compound semiconductors such as GaAs and GaN, which are the mainstay materials of laser diodes, it has higher thermal conductivity, >500 W/(m・K) than copper.

AlN (Aluminum Nitride)

CVD diamond (Chemical Vapor Deposition-Diamond)

Package Example

Optical Communication Package

Laser modules, the core components of optical communications, are complex-shaped packages containing diodes, submounts, and carriers.

For the housing materials of these packages, Cu-W that have complex and micro-machinability are suitable among heatspreader materials.

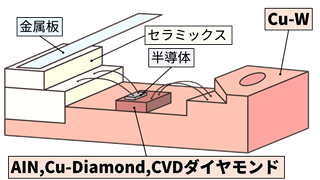

Chip Carrier and Submount

Submounts are placed just below the laser diode to mitigate differences of the coefficient of thermal expansion with the parts below.

In addition to AlN and Cu-W with excellent thermal conductivity, Cu-Diamond is used for high-power lasers.

Also, micro-machined Cu-W is suitable for chip carriers.

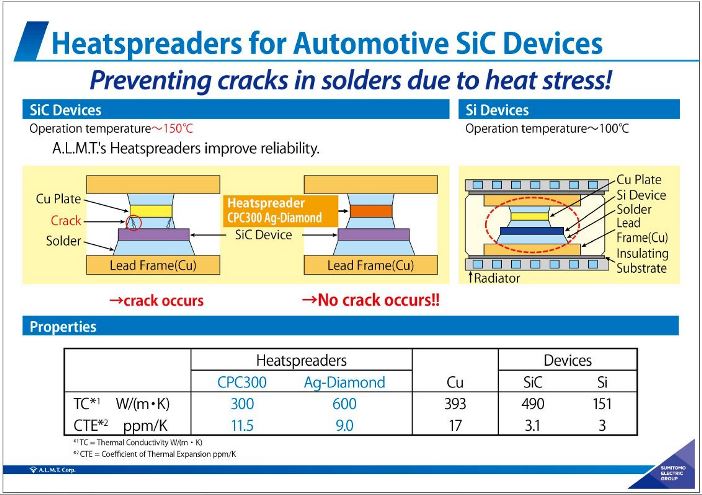

Heatspreaders for automotive

Contributing to Safe Driving of Electric and Hybrid Vehicles

With a view of realizing decarburization, the global markets for EVs and HVs (PHVs and PHEV) are expected to grow. Power devices are indispensable for power control and power conversion in electric vehicles equipped with the batteries and motors. Especially for inverters and converters that support higher powertrain output, high-efficiency power semiconductor materials like SiC (silicon carbide) and modules cooled from both sides are utilized, where heat dissipation is regarded as important. HV internal combustion engines also require a heatspreader for the component such as fuel injection controllers and radiators, which are essential for safe driving. Our heatspreaders with high thermal conductivity contribute to the development of safe and secure automobiles.

| Applications | PCU(Power control unit) for Hybrid vehicle, Inverter and ECU for Electric vehicle, etc. |

|---|

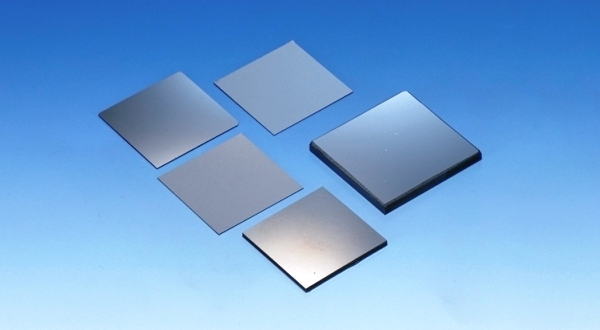

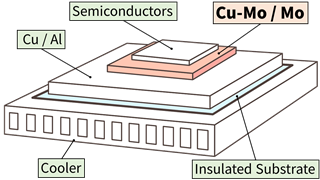

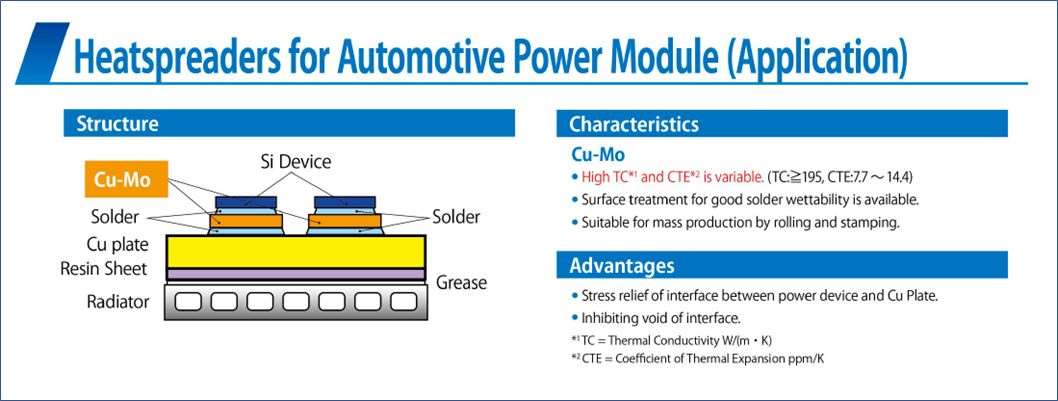

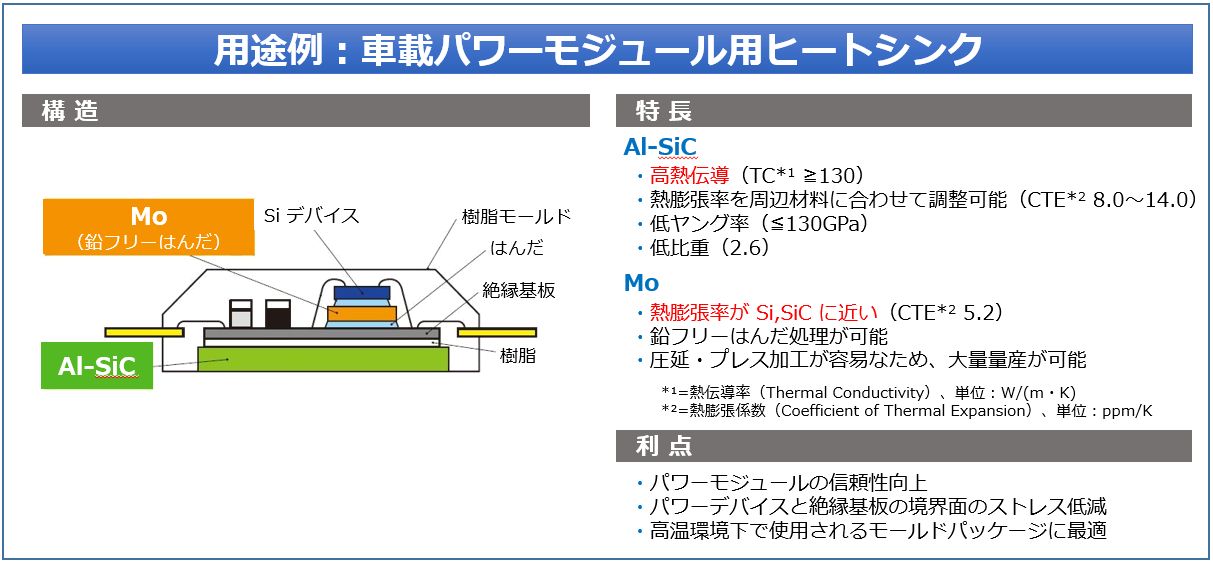

Cu-Mo (Copper-Molybdenum)

-

This is a composite material of copper (Cu), a high thermal conductivity metal, and molybdenum, a low thermal expansion metal. Its composition can be adjusted to have better coefficient of thermal expansion for the surrounding material. Since it is suitable for mass production with rolling and stamping process, it is possible to provide simple-shaped heatspreaders in large quantities at reasonable prices.

CPC™ (Copper, Copper-Molybdenum, Copper)

-

This is a three-layered composite with Cu-Mo sandwiched between pure coppers (Cu). The thermal conductivity and coefficient of thermal expansion are variable by adjusting the composition of Cu-Mo core material and the laminate ratio of Cu. In addition, since its surface is Cu, it is excellent in initial thermal dissipation. Moreover, its mass-productivity is equivalent to Cu-Mo materials.

Mo (Molybdenum)

-

It is a metal material with a high melting point close to tungsten (W).

The coefficient of thermal expansion is close to semiconductor chips (Si, GaN, SiC), and are widely used to reduce thermal stress on semiconductor devices.

It is easier to be machined than other high-melting-point metals and can be processed in complex shape.

Al-SiC (Sintered Aluminum-Silicon Carbide)

-

This is a light-weight heat dissipation material with a specific gravity of one-third that of copper (Cu).

The coefficient of thermal expansion can be customized by adjusting the composition ratio.

Also, since Young's modulus is as small as 1/2 of that of iron, it can be used as stress relaxation materials for modules.

Moreover, the surface has excellent adhesion of adhesive bonds.

Package Example

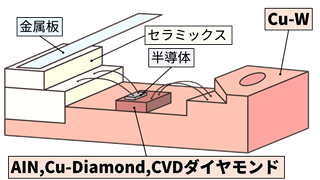

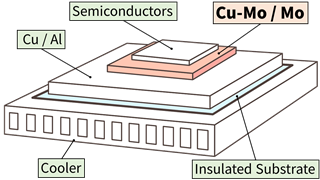

Thermal Buffer Plate

For heat dissipation of IGBT modules that control the current for motor drive, there is a cooling method that a metallic plate (Cu/Al) or a cooler is embedded.

Cu-Mo or Mo are joined between the semiconductor chip and the metallic plate to promote the heat dissipation and serve as a thermal buffer plate.

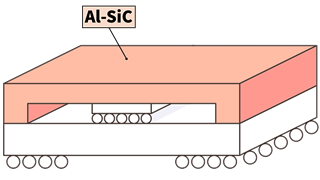

Lid (for ceramics/ organic package)

In the flipchip method, Al-SiC is used as a heat-dissipating plate called a lid that covers the package like a lid.

In addition to being lightweight, Al-SiC can be manufactured at low cost in relatively complex shapes such as lids by using dedicated molds.

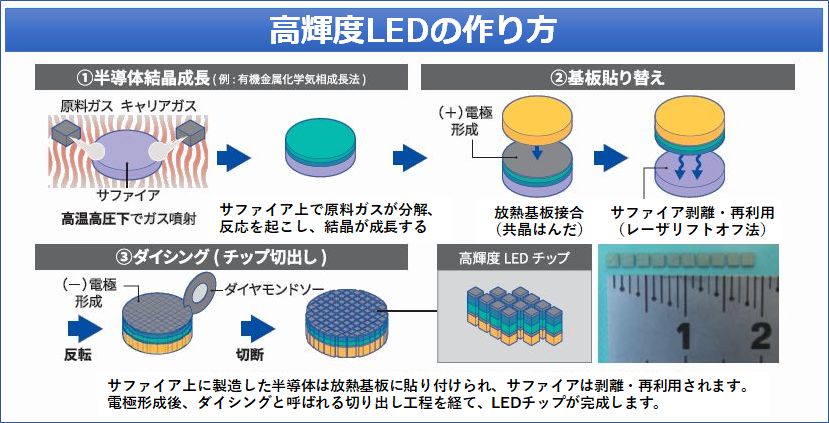

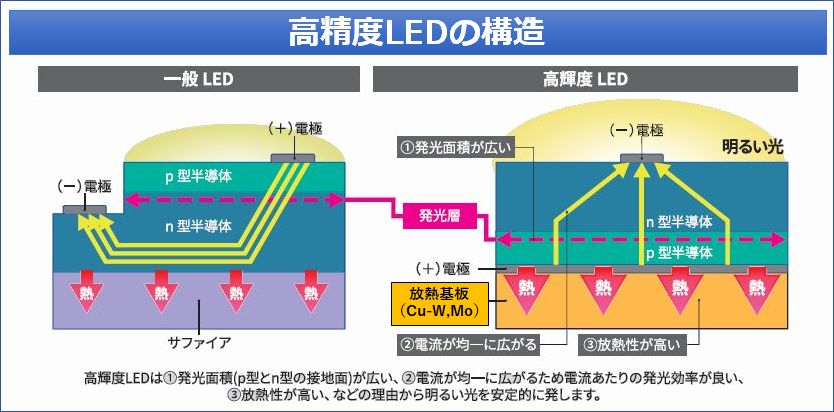

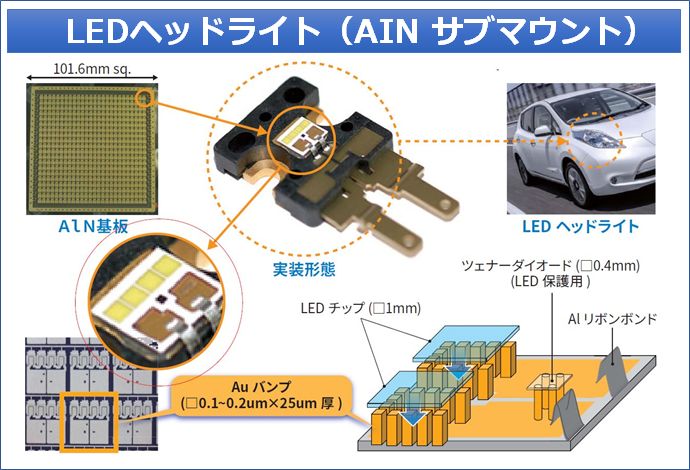

Heatspreaders for High luminance LED

Contributing to Higher Luminance LED lighting

Compared to conventional light sources, LED (Light Emitting Diode) have a longer life and are more energy-efficient. Previously, it was limited to household lighting. But, due to the progress of high luminance, the application is expanding to automobile headlights, outdoor lighting, projectors, etc. as well. In the future, by controlling wavelengths of LED, it is also expected to be applied to sterilization of drinking water, interior vegetable cultivation, and medical treatment. On the other hand, LED chips, light-emitting sources, have heat-sensitive characteristics. So, its heat dissipation is indispensable for high-luminance LED devices, which tend to have high temperatures. Our heat dissipation materials have excellent thermal conductivity, and can be also processed in complex shape with our own techniques.。

| Applications | Projectors, Headlights, Outdoor lightings, etc. |

|---|

Cu-W (Copper-Tungsten)

-

This composite material combines the high thermal conductivity characteristics of copper (Cu) with the low thermal expansion characteristics of tungsten (W), allowing the composition to be adjusted to a suitable coefficient of thermal expansion for the surrounding material.

It is also excellent in machinability, and is widely used as complex-shaped submounts and support wafers.

Cu-Mo (Copper-Molybdenum)

-

This is a composite material of copper (Cu), a high thermal conductivity metal, and molybdenum, a low thermal expansion metal. Its composition can be adjusted to have better coefficient of thermal expansion for the surrounding material. Since it is suitable for mass production with rolling and stamping process, it is possible to provide simple-shaped heatspreaders in large quantities at reasonable prices.

Mo (Molybdenum)

-

It is a metal material with a high melting point close to tungsten (W).

The coefficient of thermal expansion is close to semiconductor chips (Si, GaN, SiC), and are widely used to reduce thermal stress on semiconductor devices.

It is easier to be machined than other high-melting-point metals and can be processed in complex shape.

AlN (Aluminum Nitride)

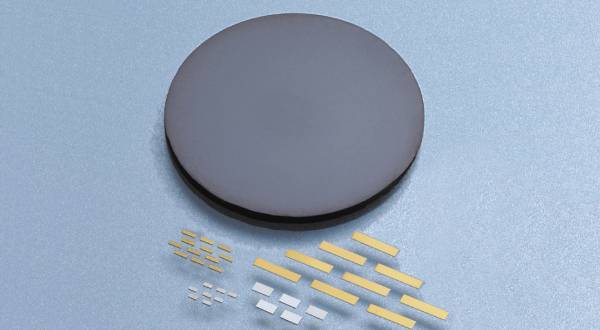

Package Example

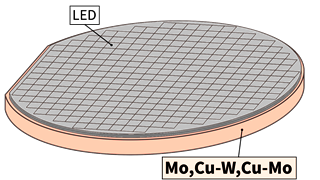

LED Substrate

For heat dissipation of LED, which are increasingly becoming more high-performance, support wafers (Mo/ Cu-W/ Cu-Mo) that can be produced to large thin-plate are suitable.

After a light-emitting layer is formed on a sapphire wafer, a heatspreader is joined to peel off the sapphire base material. Dicing the material, a small and thin LED device is completed.

Submount and carrier

Submounts may be jointed directly below the LED chip for heat dissipation and bonding stress relaxation.

AlN, Cu-W and Cu-Diamond are used for the submount, and Cu-W is used for the carriers below them.

Heatspreaders for laser

Contributing to Expansion of Applications for Semiconductor Lasers from Metal Processing to Medical Treatment

Laser processing machines are being increasingly popularized for drilling, cutting, welding, and quenching metals.

The field of lasers is also expanding including surgical laser scalpels, cancer treatments, and beauty surgery.

Semiconductor lasers (laser diodes) use compound semiconductor materials such as GaAs (gallium arsenide) and GaN (gallium nitride).

These semiconductor chips generate heat when oscillating lasers. So, the heat needs to be dissipated by a heatspreader with excellent thermal conductivity.

A.L.M.T. Corp. has many kinds of heatspreaders with high thermal conductivity and excellent coefficient of thermal expansion to match semiconductor materials.

| Applications | Welding, Cutting, Beauty care, Medical, Stack (laminated type), etc. |

|---|

Cu-W (Copper-Tungsten)

-

This composite material combines the high thermal conductivity characteristics of copper (Cu) with the low thermal expansion characteristics of tungsten (W), allowing the composition to be adjusted to a suitable coefficient of thermal expansion for the surrounding material.

It is also excellent in machinability, and is widely used as complex-shaped submounts and support wafers.

AlN (Aluminum Nitride)

Cu-Diamond (Copper-Diamond)

-

This is a composite material of copper (Cu), a high thermal conductivity metal, and diamond, which has the highest thermal conductivity of any natural material.

While having a coefficient of thermal expansion close to compound semiconductors such as GaAs and GaN, which are the mainstay materials of laser diodes, it has higher thermal conductivity, >500 W/(m・K) than copper.

CVD diamond (Chemical Vapor Deposition-Diamond)

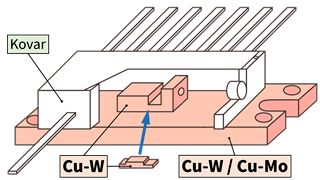

Package Example

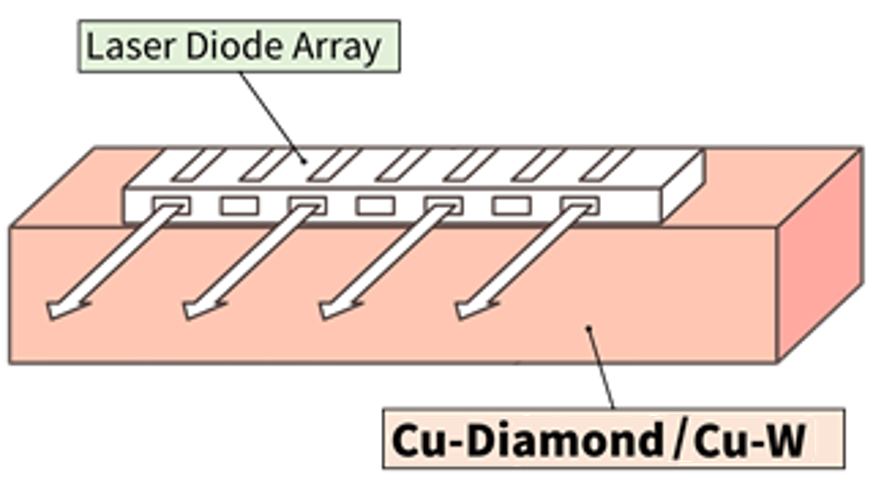

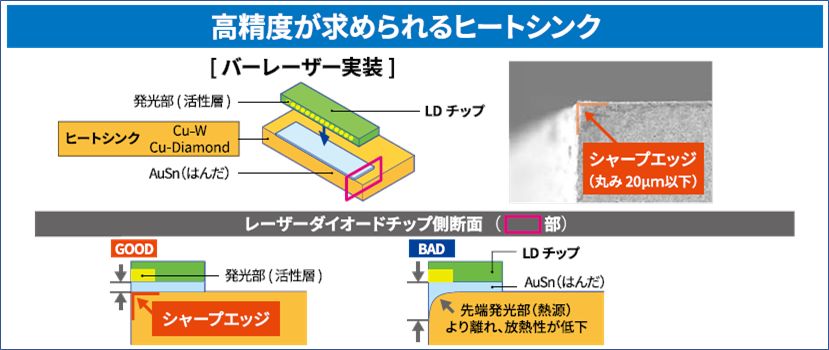

Pumping Bar Type

Heat dissipation is important to maintain the performance of bar laser semiconductors that emit laser light at high output.

Cu-W and Cu-diamond are suitable for submounts directly below the exit section, since they have high thermal conductivity and sharp-edge processing is available not to prevent laser emission.

Submount for Single Emitter

The high-power fiber laser machine is embedded with many laser diodes (single-emitter-type).

AlN and Cu-W are used for submounts located directly below the injection part, where it is required to match a coefficient of thermal expansion with surrounding materials and to have high thermal conductivity.

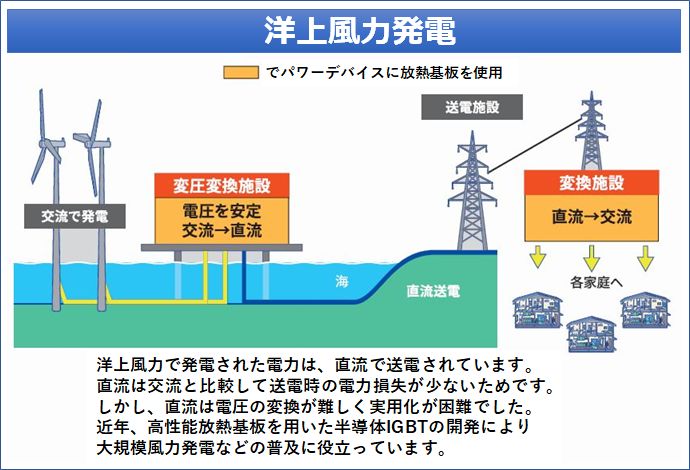

Heatspreaders for power generation

Contributing to Expansion of Offshore Wind Power Generation

The shift from coal or nuclear power generation to renewable energy is on progress worldwide.

Wind power generation, one type of the renewable energy, had to be located in a limited area in order to secure stable air volume and prevent the noise.

Then, to deploy the generator onto offshore is gaining attention.

Since there is no obstruction around it, air volume suitable for power generation can be stably obtained, and a number of generators can also be deployed at a close range.

For long-distance power transmission from the offshore to the land, direct current (DC), less loss at the time of power transmission, is considered ideal. But, to transform electrical energy to/from alternating current (AC), the substation loss was made unavoidably.

For this reason, in addition to high conversion efficiency, more compact and maintenance-free properties are required for the power devices due to offshore conditions.

In order to realize stable dissipation of heat generated by semiconductor chips that support our infrastructure for a long period of time, our highly reliable heat-dissipating plate (heatspreader) is ideal.

| Applications | Offshore wind power generation, etc. |

|---|

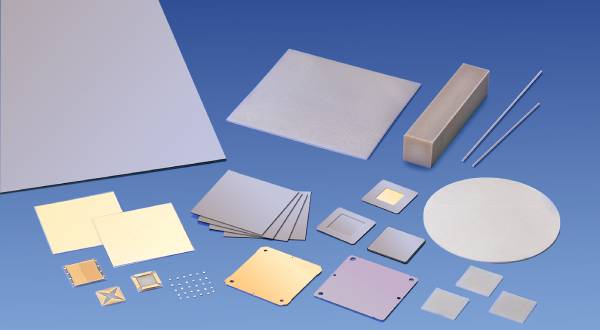

Cu-Mo (Copper-Molybdenum)

-

This is a composite material of copper (Cu), a high thermal conductivity metal, and molybdenum, a low thermal expansion metal.

Its composition can be adjusted to have better coefficient of thermal expansion for the surrounding material.

Since it is suitable for mass production with rolling and stamping process, it is possible to provide simple-shaped heatspreaders in large quantities at reasonable prices.

Mo (Molybdenum)

-

It is a metal material with a high melting point close to tungsten (W).

The coefficient of thermal expansion is close to semiconductor chips (Si, GaN, SiC), and are widely used to reduce thermal stress on semiconductor devices.

It is easier to be machined than other high-melting-point metals and can be processed in complex shape.

Package Example

Base plate for power module

For power modules, in order to mitigate the difference of thermal expansion between IGBT chips and packaging materials, to have Molybdenum (Mo) chip carriers between them as thermal buffer plates is effective.

In addition, it can efficiently dissipate heat by jointing Cu-Mo plates to the packages.

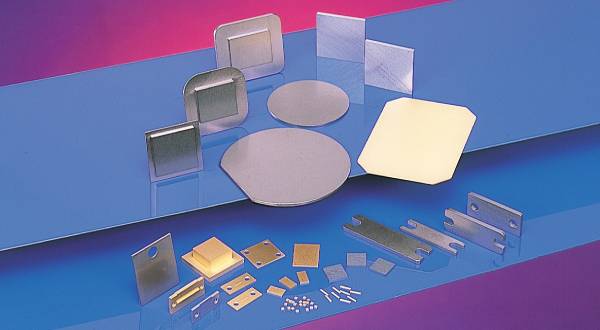

Heatspraders for electric railways

Contributing to Expansion of High-Speed Railway Network

Japan and Europe have led the world in the fields of high-speed railways such as bullet trains. But, in recent years, the networks are being applied rapidly in China and other Asian countries as well. The high-speed train converts the high-voltage current collected from the pantograph into a current suitable for motor drive by the main converter (converter and inverter). And an IGBT (insulated-gate bipolar transistor) is embedded in the control. Because they run at high speed, they must be compact and lightweight, and the heat generated from power devices is regarded as a problem. A.L.M.T. Corp. has molybdenum (Mo) -based heatspreaders that have heat dissipation properties and shape stabilities suitable for IGBT modules of electric railways.

| Applications | Inverters, etc. |

|---|

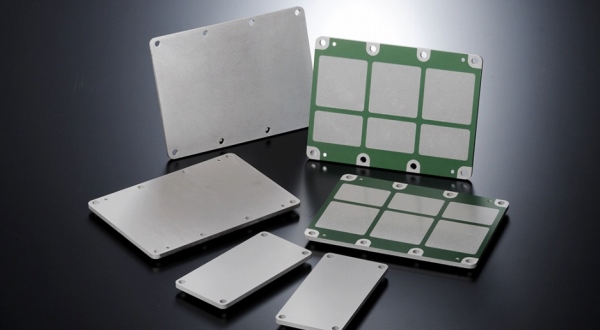

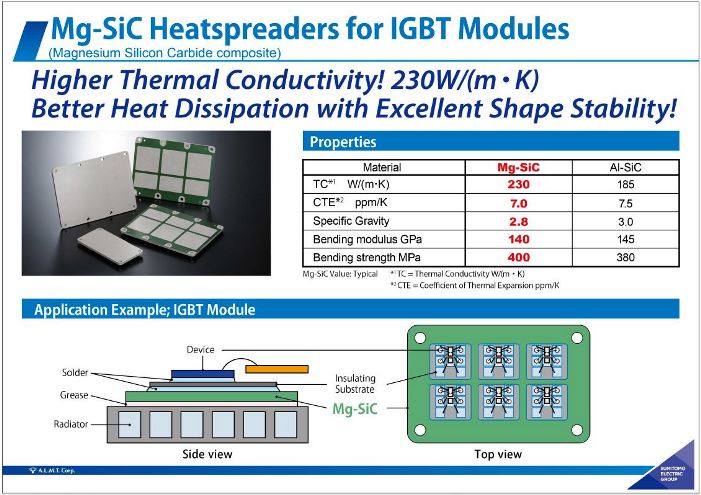

MAGSICTM (Magnesium-Silicon Carbide)

-

This is a lightweight composite material manufactured by infiltrating Silicon Carbide (SiC) with Magnesium (Mg) using our unique technology.

It has a better coefficient of thermal expansion and thermal conductivity compared with Al-SiC. And also, large-scale mass-production is available.

The composition ratio of Mg and SiC can be changed to adjust the coefficient of thermal expansion.

And, it is possible to keep its warpage less variation.

Package Example

Base plate for power module

For power modules, which are represented by IGBT that control motors for high-speed trains, the heat dissipation to the increased power density is regarded as important.

MAGSIC has a higher thermal conductivity than conventional material Al-SiC and less thermal deformation due to high-temperature operation for a long time.

Heatspreaders for industrial machinery

Contributing to the Precise Operation of Robots

High-output motors play a role in the operation of industrial machines such as robots and elevators, which are used in factories, offices, hospitals, and many other locations. To support their precise control, the motor is equipped with a high-performance power semiconductor module, and the efficient heat dissipation is the point for the stable operation. A.L.M.T. Corp. has heat-dissipating plates (heatspreaders) with high thermal conductivity and adjustable coefficient of thermal expansion for semiconductor chips.

| Applications | Industrial robots, Industrial equipment, etc. |

|---|

Cu-W (Copper-Tungsten)

-

This composite material combines the high thermal conductivity characteristics of copper (Cu) with the low thermal expansion characteristics of tungsten (W), allowing the composition to be adjusted to a suitable coefficient of thermal expansion for the surrounding material.

It is also excellent in machinability, and is widely used as complex-shaped submounts and support wafers.

Cu-Mo (Copper-Molybdenum)

-

This is a composite material of copper (Cu), a high thermal conductivity metal, and molybdenum, a low thermal expansion metal.

Its composition can be adjusted to have better coefficient of thermal expansion for the surrounding material.

Since it is suitable for mass production with rolling and stamping process, it is possible to provide simple-shaped heatspreaders in large quantities at reasonable prices.

Ag-Diamond (Silver-Diamond)

-

Silver has the highest thermal conductivity of metals, and diamond has the highest thermal conductivity of natural materials.

Alloying them with our technology, we have achieved heatspreader with high thermal conductivity, over 600 W/ (m・K).

It is possible to manufacture larger ones than conventional diamond-based materials, and silver brazing is also available.

Package Example

Thermal Buffer Plate

For heat dissipation of IGBT modules that control the current of motor drive, there is a method in which a metallic plate (such as Cu/ Al)] or a cooler is embedded.

Cu-Mo and Ag-Diamond are joined between the semiconductor chips and the metal plate to promote heat dissipation and function as a thermal-stress buffer material.

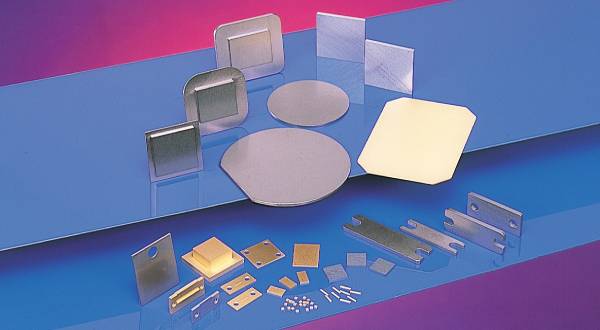

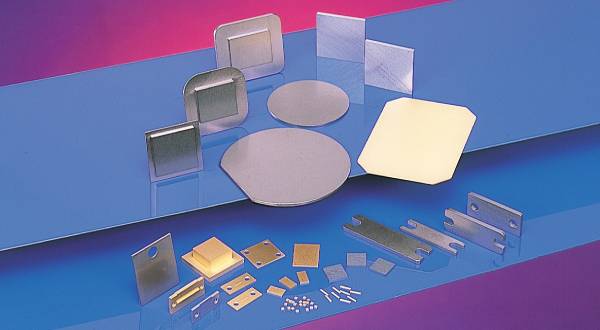

Lineups of Cu-W (Copper-Tungsten) heatspreaders

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃ [ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Cu-W | W-6 | 94W-6Cu | This Cu-W with a low coefficient of thermal expansion has the close coefficient to GaAs and GaN. And, it prevents mismatches of the thermal expansion. | 6.4 | 141 |

| W-10 | 89W-11Cu | The coefficient of thermal expansion matches alumina. So, it is widely used in ceramic packages using alumina. | 7.9 | 174 | |

| W-15 | 85W-15Cu | The same thermal expansion coefficient as that of beryllia ceramics, widely used for ceramics package using beryllia. It is also widely used for packages using both alumina and kovar because its thermal expansion coefficient is an intermediate value between those of alumina and kovar. | 8.6 | 184 | |

| W-20 | 80W-20Cu | It matches the coefficient of thermal expansion of Kovar and is widely used in metal packages using Kovar. | 9.8 | 200 | |

| W-10N | 89W-11Cu | The coefficient of thermal expansion matches alumina. It is widely used in ceramic packages using alumina.W-10N can provide Cu-W (near-net Cu-W) without periphery process by manufacturing a dedicated mold. | 7.9 | 200 | |

| W-10T | 89W-11Cu | Although it has the same thermal expansion coefficient as that of W - 10, the thermal conductivity is improved by a special manufacturing method; moreover, it is widely used for sub-mount applications for high power lasers because it can keep warp small. | 7.9 | 205 |

Lineups of Cu-Mo (Copper-Molybdenum) heatspreaders

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃ [ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Cu-Mo | CM-15 | 85Mo-15Cu | This Cu-Mo has a low coefficient of thermal expansion, and has the close coefficient to GaAs and GaN. And, it prevents mismatches in thermal expansion. | 7.6 | 148 |

| PCM30 | 70Mo-30Cu | This material keeps thermal expansion low, and can be manufactured by cost-effective manufacturing processes such as rolling and stamping. | 7.5 | 195 | |

| PCM35 | 65Mo-35Cu | This has the same coefficient of thermal expansion as that of alumina, widely used for ceramic package using alumina. | 7.8 | 210 | |

| PCM40 | 60Mo-40Cu | As its thermal expansion coefficient is intermediate value between the devices (Si, GaAs, GaN, SiC) and copper or aluminum, it is widely used as a stress cushioning material in case devices are mounted on a copper or aluminum plate. | 8.2 | 220 | |

| RCM60 | 40Mo-60Cu | As its thermal expansion coefficient is intermediate value between the devices (Si, GaAs, GaN, SiC) and copper or aluminum, it is widely used as a stress cushioning material when devices are mounted on a copper or aluminum plate. | 10.5 | 275 |

Lineups of Mg-SiC (Magnesium-Silicon Carbide) heatspreaders

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~120℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Mg-SiC | Mg-SiC | 18Mg-SiC | Since it is lightweighted, it is suitable to be used in larger size; in addition, it has stable warpage, excellent high thermal conductivity and heat dissipation. | 7.0 | 230 |

Lineups of Mo (Molybdenum) heatspreaders

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃ [ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Mo | Mo | Mo | The thermal expansion is close to semiconductor (Si, GaN, SiC). It is widely used to reduce thermal stress on semiconductors. | 5.7 | 142 |

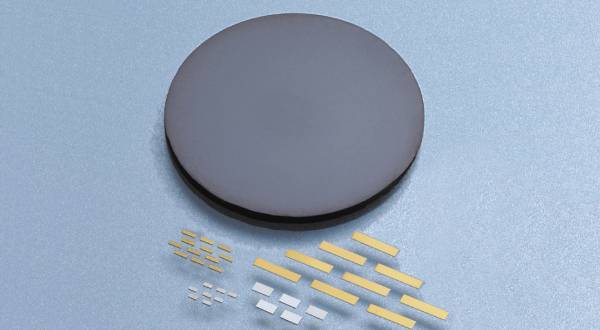

Lineups of Cu-Diamond (Copper-Diamond) heatspreaders

Scroll to view all

| Material | Trade Name | Features | Coefficient of Average Linear Thermal Expansion R.T.~400℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|

| Cu-Diamond | DC60 | The heatspreader with high thermal conductivity has coefficient of thermal expansion suitable for compound semiconductors (GaAs, GaN). | 6.0 | 550 |

| DC70 | 6.5 | 500 |

Lineups of AlN (Aluminum Nitride) heatspreaders

Scroll to view all

| Material | Trade Name / Composition |

Features | Coefficient of Average Linear Thermal Expansion R.T.~400℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|

| AlN | AlN(200W) | It is useful when insulation and patterns are required. | 4.5 | >200 |

| AlN(170W) | 4.5 | >170 |

Lineups of CPC (Copper, Copper-Molybdenum, Copper) heatspreaders

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| CPC | CPC141 | Cu/Cu-Mo/Cu | Has the same thermal expansion coefficient as that of alumina ceramic, widely used for ceramic package using alumina. As the surface is copper with high thermal conductivity, it has excellent heat diffusion. | 7.6 | 200 |

| CPC232 | Laminated in "Cu:Cu-Mo:Cu=2:3:2(thickness)" to adjust the coefficient of thermal expansion and thermal conductivity. | 8.4 | 235 | ||

| CPC111 | Laminated in "Cu:Cu-Mo: Cu=1:1:1 (thickness)" to adjust the coefficient of thermal expansion and thermal conductivity. | 9.8 | 260 | ||

| CPC212 | Laminated in "Cu:Cu-Mo: Cu=2:1:2 (thickness)" to improve the thermal conductivity to 300W/ (m・K).It is widely used to realize the performance of high-power devices (GaN, SiC). | 12.1 | 300 | ||

| CPC-300 | It has a very high thermal conductivity, 300W/ (m・K), and is widely used to realize the high performance of high-power devices (GaN, SiC).The thin plates, 0.5mm, are also available. | 12.1 | 300 |

Lineups of CVD diamond (Chemical Vapor Deposition-Diamond) heatspreaders

Scroll to view all

| Material | Features | Coefficient of Average Linear Thermal Expansion R.T.~100℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|

| CVD-Diamond | This is a diamond heatspreader of 0.1 to 0.4 mm produced by the CVD method (Chemical Vapor Deposition). | 2.3 | >1000 |

Lineups of Al-SiC (Sintered Aluminum-Silicon Carbide) heatspreaders

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~120℃ [ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Al-SiC | β8 | 70SiC-30Al | By using a special mold, it can be manufactured cost-effectively without processing. The thermal expansion coefficient is variable according to the package type. | 8.0 | 140 |

| β9 | 65SiC-35Al | 9.0 | 130 | ||

| β14 | 45SiC-55Al | 14.0 | 160 |

Lineups of Ag-Diamond (Silver-Diamond) heatspreaders

Scroll to view all

| Material | Trade Name | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|

| Ag-Diamond | AD90 | The thermal conductivity is 600W/(m・K) and higher than Cu-Diamond. It is applicable to large size purpose as 50×50m |

10.5 | 600 |

バーレーザ実装イメージ

ヒートシンクとなる AIN、Cu-W、Cu-Diamond はシャープエッジ(ピン角)に加工できるため光路を妨げず、エッジ先端部で発光する LD 部の放熱性を高めます。また、はんだ流れを制御する技術により、安定したレーザ性能を実現します。

自動車用パワーモジュール(Cu-Mo)

自動車用パワーモジュール(Mo)

IGBTモジュール

自動車用SiCデバイス

高輝度LEDの作り方

高輝度LEDの構造

LEDヘッドライト(AIN サブマウント)

洋上風力発電