Various cutting

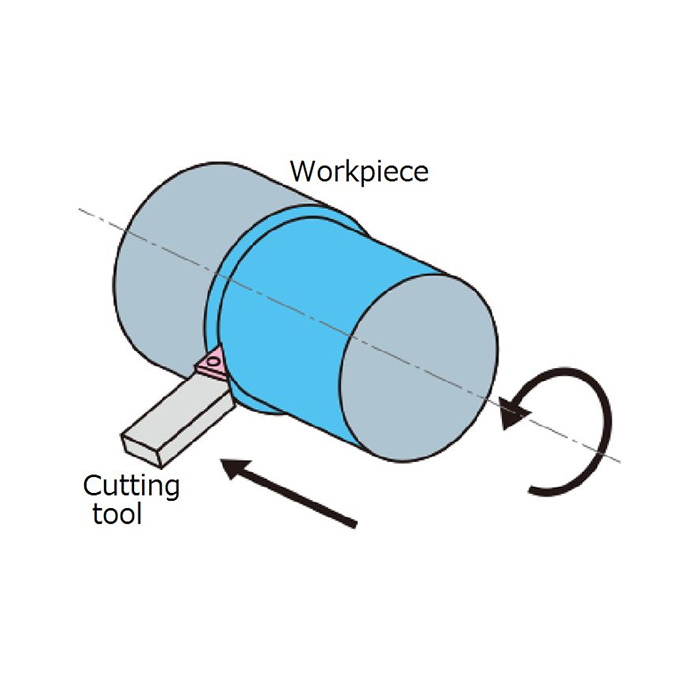

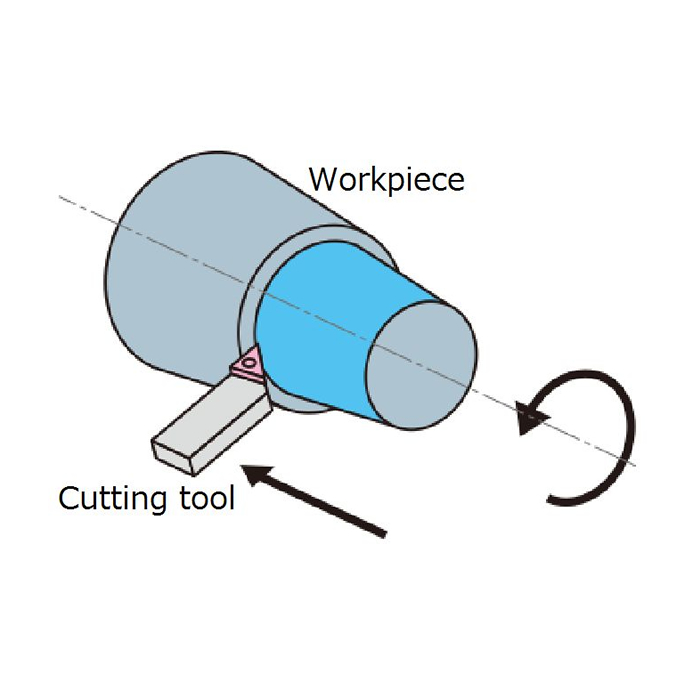

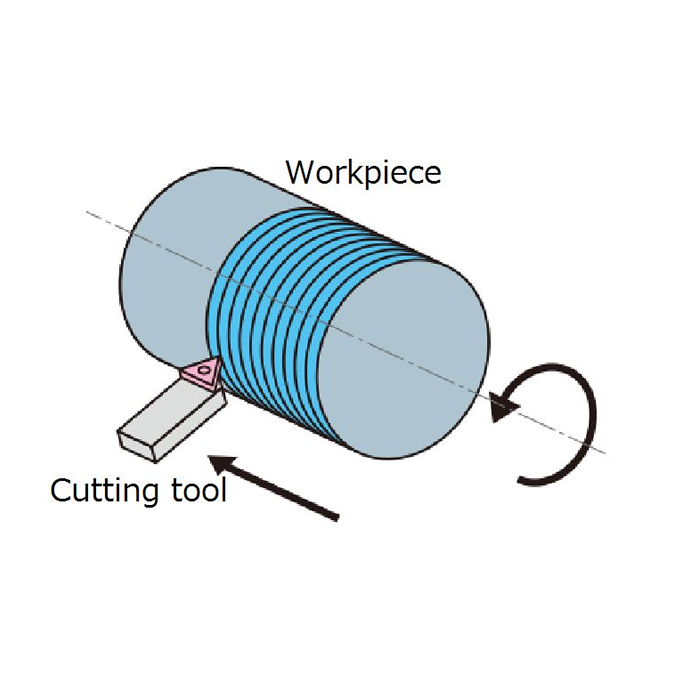

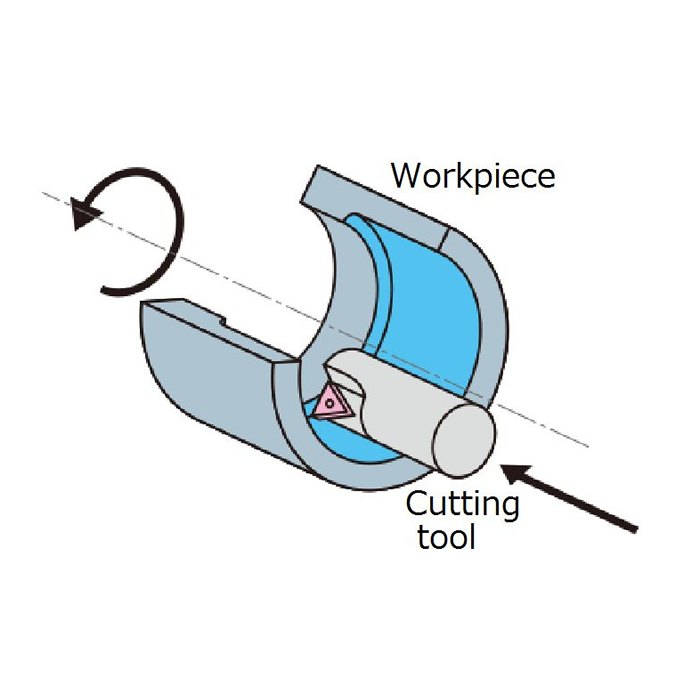

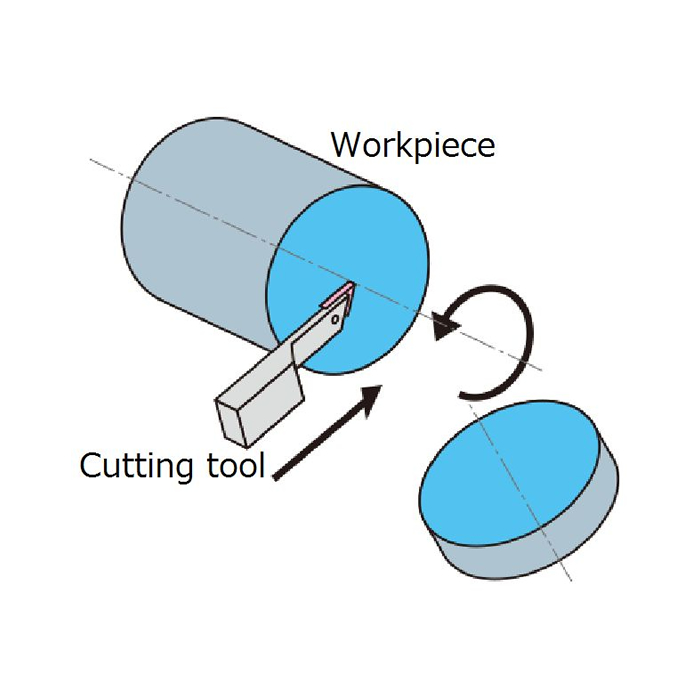

Turning

Turning is a process of rotating a workpiece and cutting it with a cutting tool.

Lathe machining is typical turning, which machines the workpiece by a general-purpose lathe or an NC lathe using various types of cutting tools. The material and shape of the blade changes according to application.

Outer round cutting

Outer round cutting Taper cutting

Taper cutting Tread cutting

Tread cutting Drilling

Drilling Boring

Boring Piercing

Piercing Facing

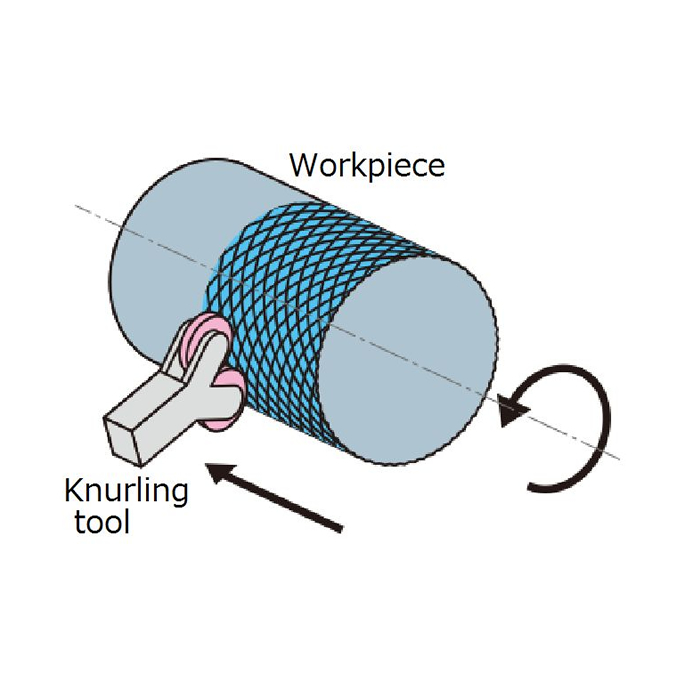

Facing Knurling

Knurling

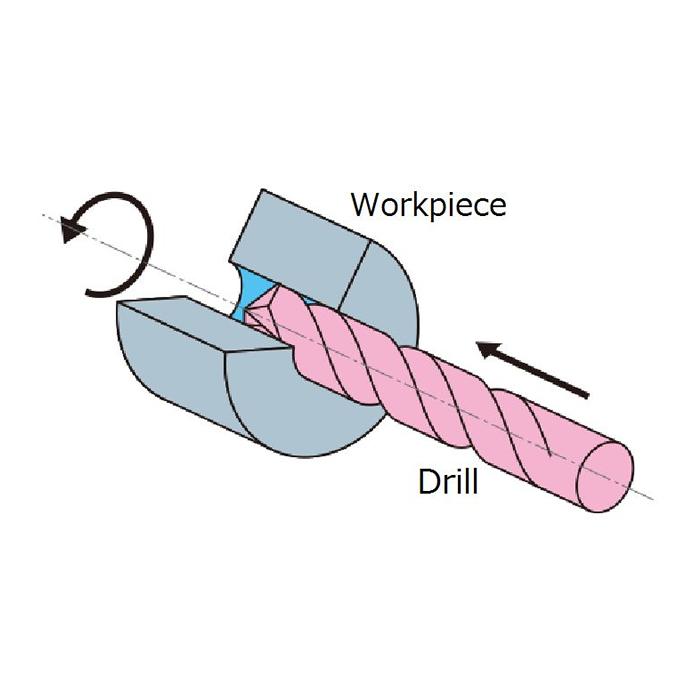

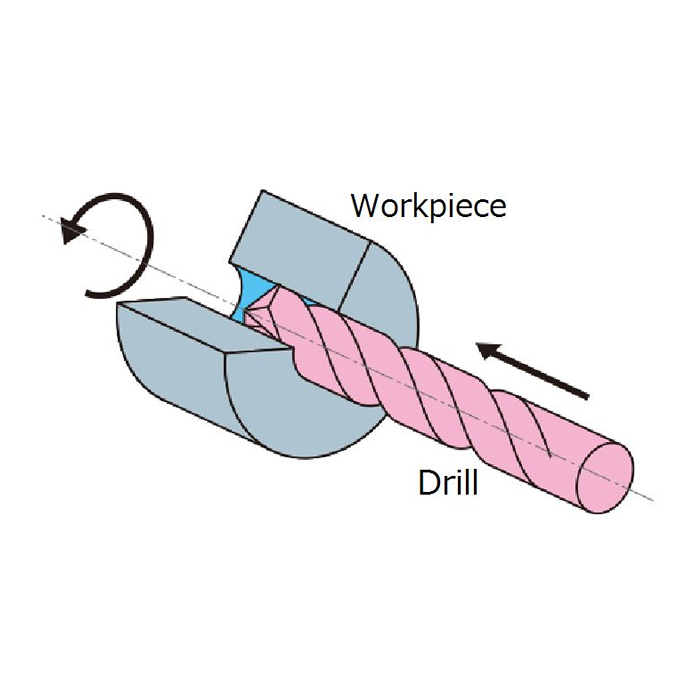

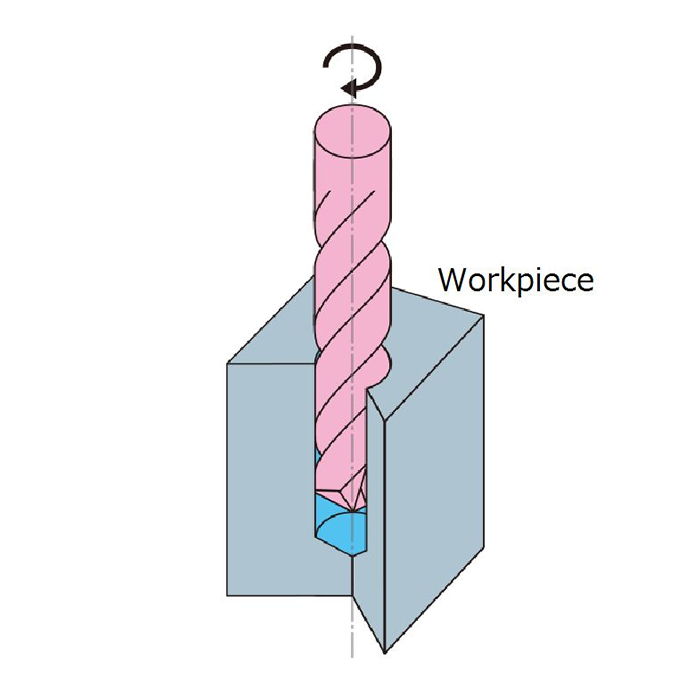

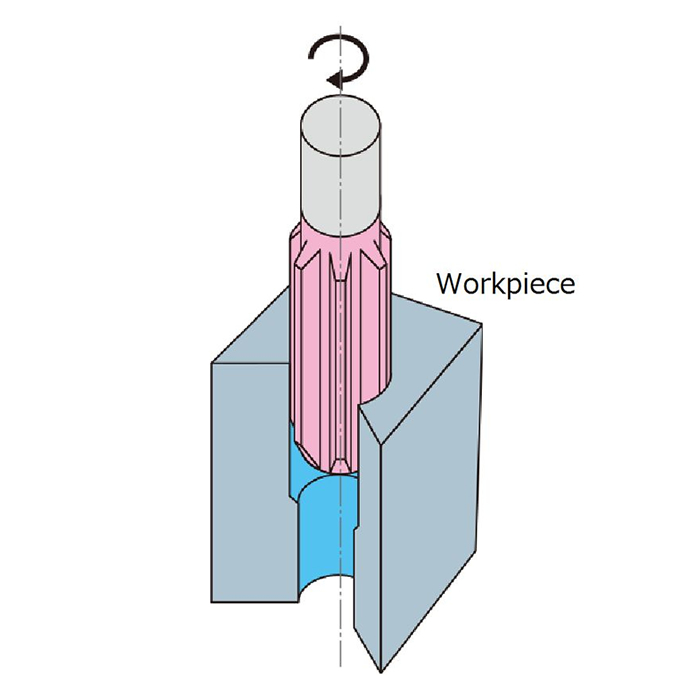

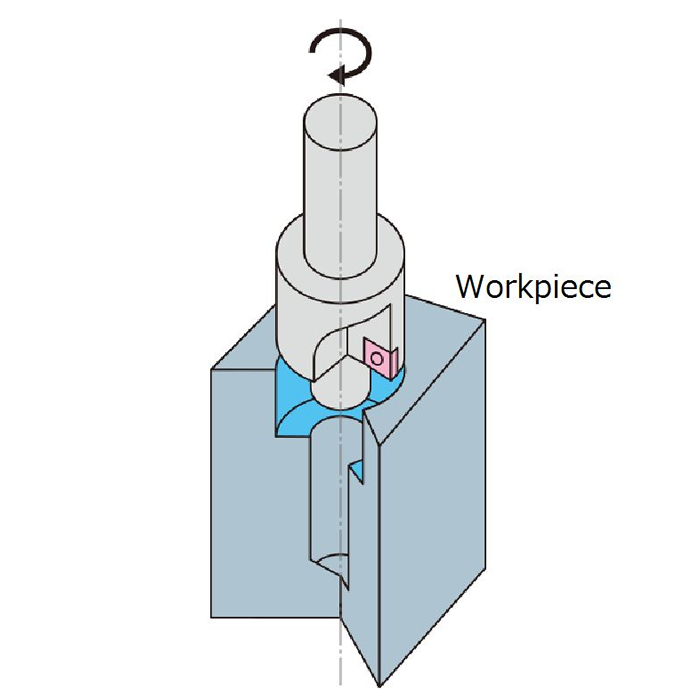

Hole drilling

Drilling is generally a process of attaching a drill to a drilling machine or a machining center to drill a hole in a workpiece. Drilling is also performed with a lathe or a milling machine. A reamer is mainly used for finishing holes. In addition, spot facing, boring, tapping and broaching are also classified as drilling.

Hole drilling

Hole drilling Reaming

Reaming Spot facing

Spot facing Tapping

Tapping

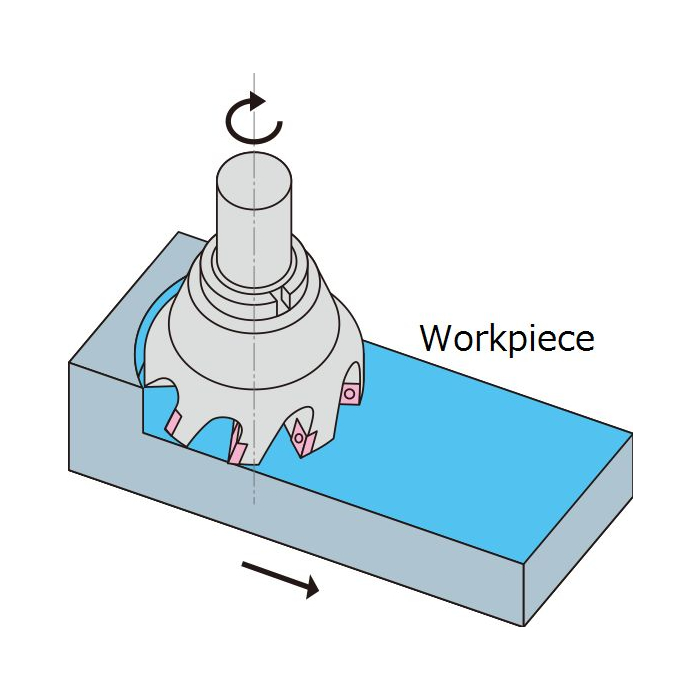

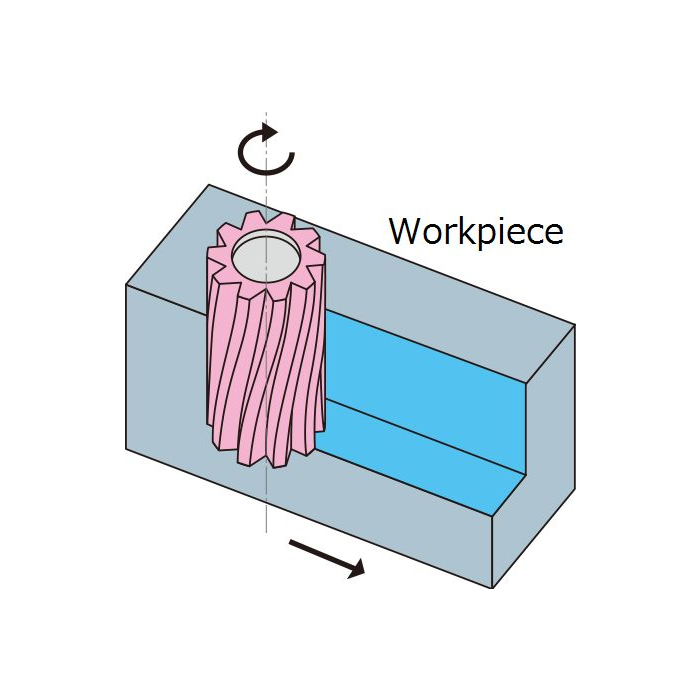

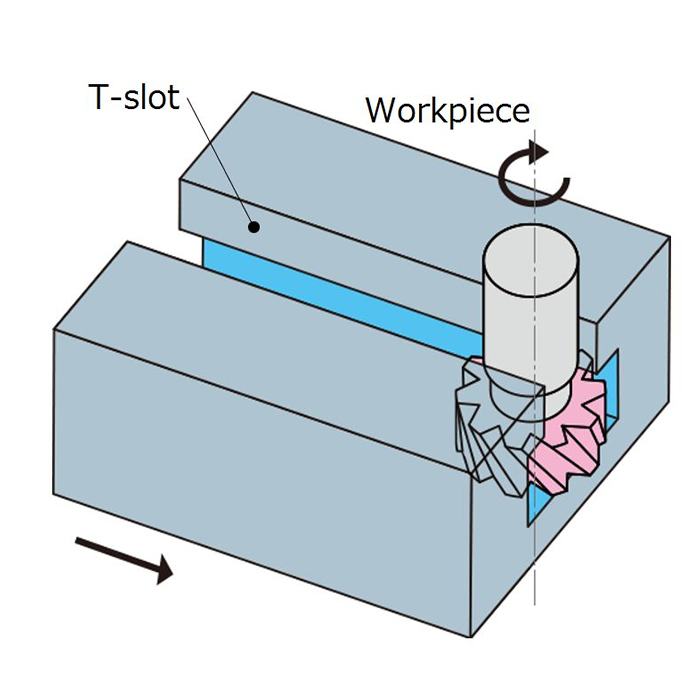

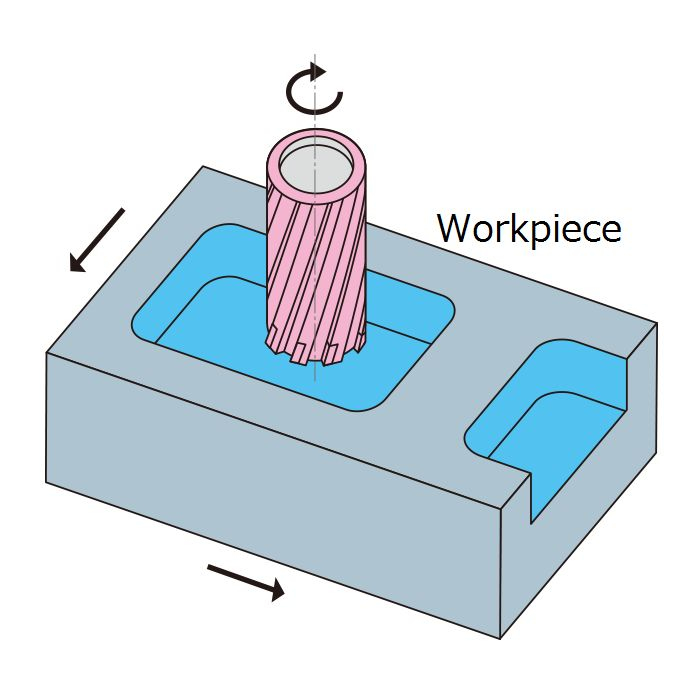

Milling

Milling is a cutting process that uses a milling machine or a machining center, using a milling tool with multiple blades.

Milling tools have various shapes, and the machining form changes according to the shape of the workpiece, including flat machining, side machining, and groove machining. End milling is also a type of milling.

Flat work

Flat work Side milling

Side milling T grooving

T grooving End milling

End milling

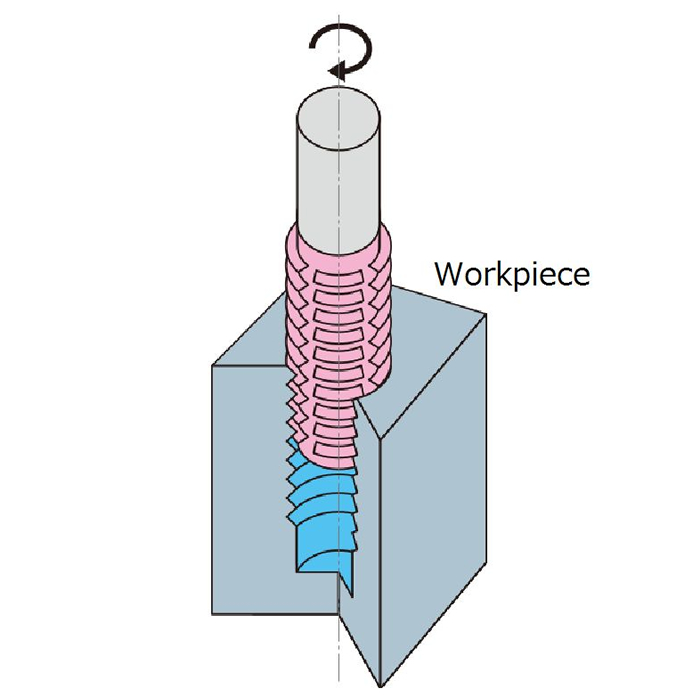

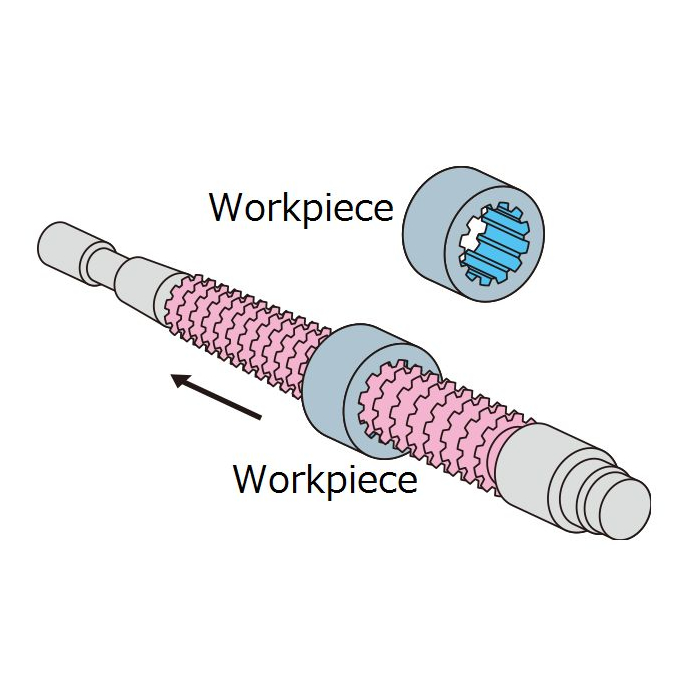

Broaching

Broaching is a process using a tool called broach, where a number of cutting edges are arranged in order of dimension along the axis of the outer periphery of a bar body in the broach machine to machine the surface of a workpiece or the inner surface of a hole.

Broaching

Broaching

- Please feel free to contact us

-

-

- Inquiries by email

- For emailing form

-

- Inquiries by phone

- For sales office

-