New Product Information

Uniform tungsten powder

Using our unique technology, we developed tungsten powder with more uniform grains than conventional products. Beyond improved handling performance by the low-volumed powder, it is possible to form a uniform powder layer. Moreover, layer thickness and shrinkage during sintering can be controlled.

To see the whole table, scroll sideways.

| Type | Particle size(μm) | W(%) | O(%) | Fe(%) | Mo(%) | NVR(%) |

|---|---|---|---|---|---|---|

| W-U010 | 0.9 to 1.4 | ≥99.9 | ≤0.20 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U020 | 1.5 to 2.4 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U030 | 2.5 to 3.4 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U040 | 3.5 to 4.4 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U050 | 4.5 to 5.4 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U100 | 8.0 to 12.0 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U150 | 13.0 to 17.0 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U200 | 18 to 22 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U250 | 23 to 28 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

Particle size is the average grain diameter by the Fischer method.

W (%) is the remainder obtained by subtracting F.C, Fe, Mo and NVR from 100.

*NVR:Nonvolatile content

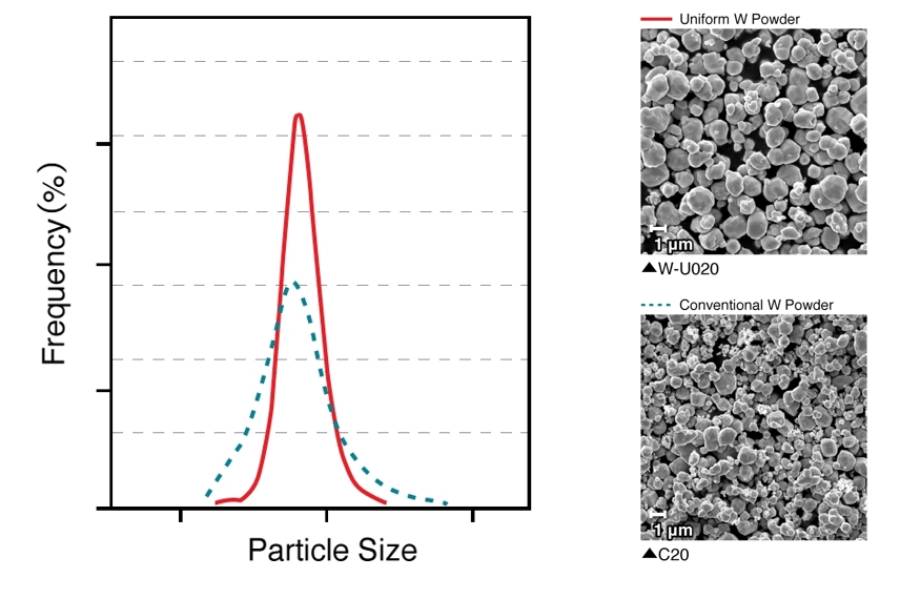

Paticle distribution of uniform tungsten powder

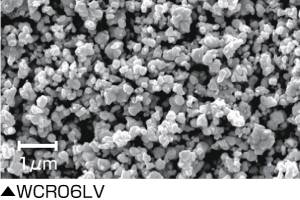

Low volume tungsten carbide powder

We manufacture tungsten carbide powder with much lower volume than conventional one.

The powder can also lower alloy shrinkage, and raise productivity according to various applications.

To see the whole table, scroll sideways.

| Type | Particle size(μm) | T.C(%) | F.C(%) | Fe(%) | Mo(%) | Cr(%) |

|---|---|---|---|---|---|---|

| WC05LV | ― | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ― |

| WC06LV | 0.5 to 0.7 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ― |

| WC08LV | 0.7 to 0.9 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ― |

| WC10LV | 0.9 to 1.1 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ― |

| WCR05LV | ― | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | 0.80 to 0.90 |

| WCR06LV | 0.5 to 0.7 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | 0.80 to 0.90 |

| WCR07LV | 0.7 to 0.9 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | 0.80 to 0.90 |

Particle size is the average grain diameter by the Fischer method.

* indicates the converted grain diameter by the BET method.

TC:Total Carbon

FC:Free Carbon

- Expected effects

- Lower shrinkage during sintering the pressed powder. (commonalizing molds with tungsten carbide powder with different grain size)

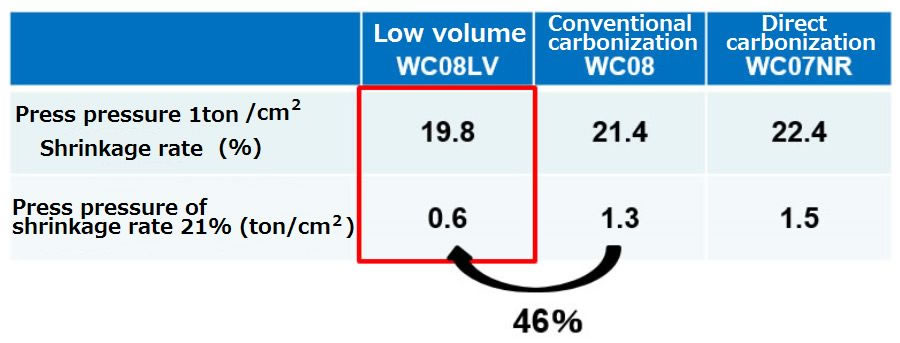

- Possible to reduce molding pressure. ( preventing cracks in pressed body with complex shape)

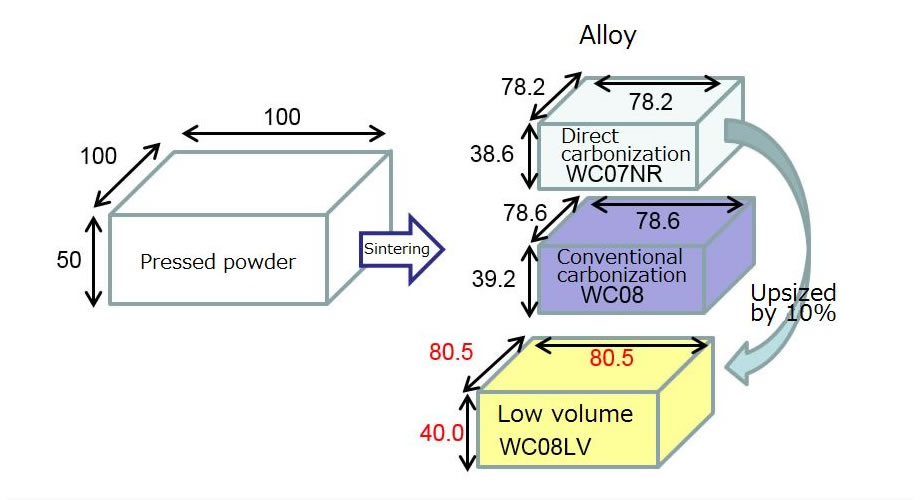

- Possible to upsize sintered body.

- Possible to sinter the powder more efficiently per batch. (improving productivity in mixing process)

- Possible to reduce mixing time.

Upsizing sintered body. Comparison with 0.8 µm tungsten carbide powder

Reducing molding pressure

- Tungsten Technical information