R&D of Diamond/CBN tools

Research and development for high-efficiency, high-performance, and environmental friendliness

Tools made from diamond, the hardest substance in the world, and from cubic boron nitride (CBN) with hardness near to diamond are used in various industries around the world.

Recently, technological innovation has further accelerated, with the increasing demand for diamond/CBN tools. Conducting research and development, we are developing tools to meet various needs.

| Example of applications | Improved efficiency, longer life and higher accuracy in finishing holes of sintered alloy and cast iron. |

|---|

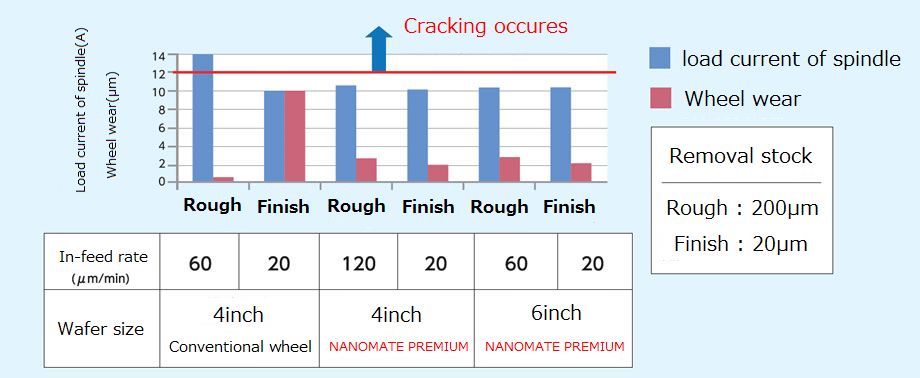

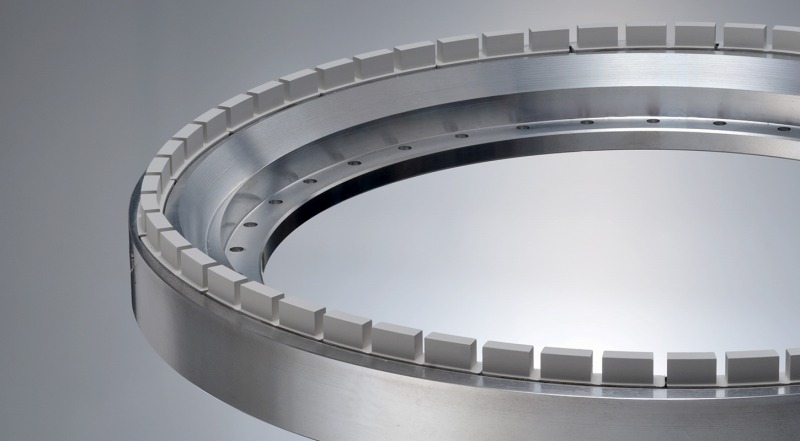

Diamond wheel for grinding semiconductor material “Nanomate Premium” series

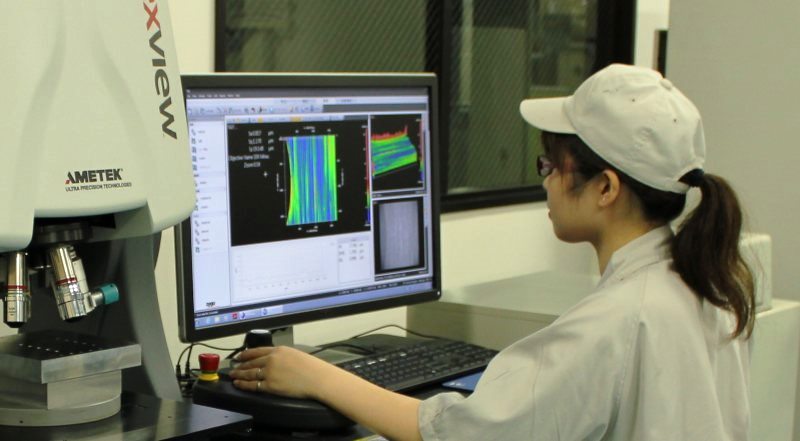

We are developing diamond wheels for grinding various semiconductor materials.

Making full use of the know-how of semiconductor material processing we have cultivated over the years, we have realized a wheel with a dedicated design for characteristics of each material.

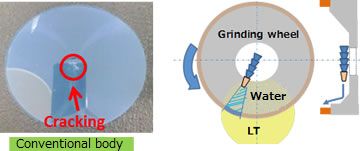

Wheels for grinding LiTaO3 (LT) wafer

- Problems when grinding LT wafer

-

- ・Cleaving occurs in LT wafer because of its characteristic of a single crystal; even a slight stress causes the whole to crack.

- ・Thermal expansion coefficient varies significantly according to the crystal orientation. When it is exposed to thermal change, stress distortion occurs inside, breaking it instantaneously.

- LT wafer achieved low damage/low load processing by bond design and new body development

-

- ・We have developed dedicated-design bond and realaized that no crack occurs when grinding wafer .

- ・It comes to be possible to prevent cracks in wafer with newly developed body that can control thermal change by supplying grinding water uniformly.

| Feed rate | 60 | 20 | 120 | 20 | 60 | 20 |

|---|---|---|---|---|---|---|

| Wafer size | 4 in. Conventional wheel |

4in. Newly developed |

6in. Newly developed |

|||

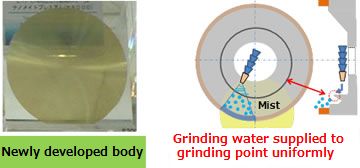

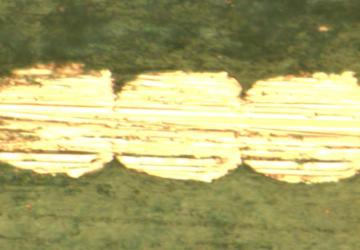

Wheel for grinding WLP/FOWLP substrate

- Problems when WLP / FOWLP substrate

-

- ・Grinding causes metal drag and resin tear.

- ・Conventional grinding wheels cause clogging of metal and resin.

Conventional wheel

Conventional wheel- Features of newly developed bond

-

- ・Grinding of elastic plastic material is possible.

- ・Drag and tear of metal and resin are suppressed.

- ・Continuous grinding by maintaining sharpness is possible.

Nanomate premium#2000

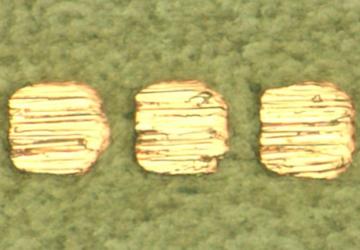

Nanomate premium#2000Wheel for grinding MEMS substrate

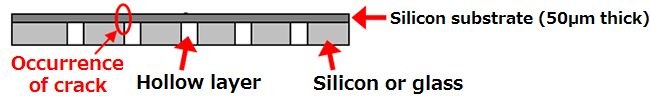

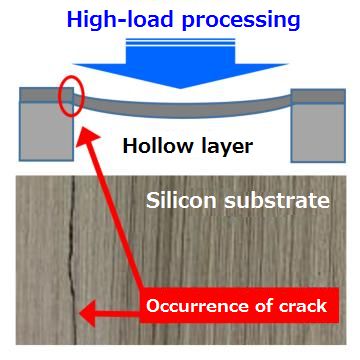

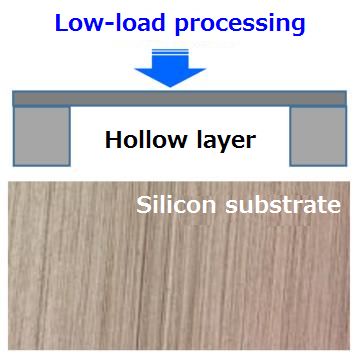

- Problems when grinding MEMS

-

- ・When grinding silicon wafer, cracks occur in the hollow layer in the silicon or glass substrate.

Current wheel

Current wheel- Features of newly developed bond

-

- ・Low load processing enables crack-free processing.

- ・Continuous grinding of through holes and deep drilling wafers is possible.

Nanomate premium#6000

Nanomate premium#6000