Our Heat spreader technology

Various surface treatment technologies

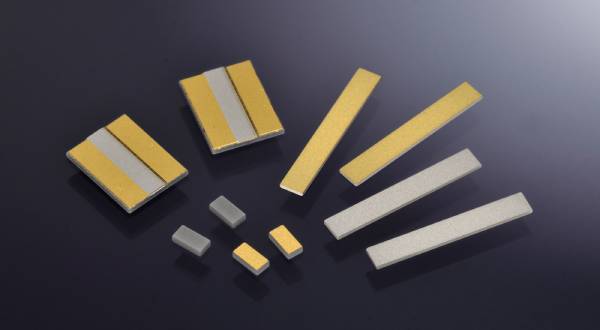

Heat spreaders require surfaces that have been adequately treated in order to bond with semiconductor elements and package members. A high-quality surface condition is necessary to provide highly reliable components that will not rust or corrode under severe environmental conditions. We have a wide variety of surface treatment facilities. As part of our integrated manufacturing process, which includes processing raw materials, we conduct various surface treatment operations such as plating and metallizing.

Plating

-

Heat spreaders need to quickly dissipate the heat generated by semiconductor operation to the radiator plate and other such places. They can be joined using various methods such as Ag brazing, Pb-free soldering, Au soldering, and Ag nano-paste. For this purpose, we can employ techniques such as Ni electro-plating, Ni-P electro-less plating, and electro-gold plating. We also perform plating that adheres well to W and Mo, despite their poor plating properties, thus ensuring excellent heat radiation.

Lead-free solder

-

We offer pre-soldered* products that simplify the production process of bonding power modular semiconductors and heat spreaders. These can improve bonding reliability, increase yield rates, and simplify the management of parts purchases.

(*These are heat spreaders that come with solder already applied)

AuSn vapor deposition

-

We use our original deposition technology to form an Au/Sn eutectic alloy solder layer on heat spreaders, which is suitable for bonding semiconductor devices. The composition ratio of Au and Sn can be adjusted to control the bonding characteristics. By forming the Au/Sn layer on the surface, there is potential to improve workability and yield rates when bonding semiconductor devices.

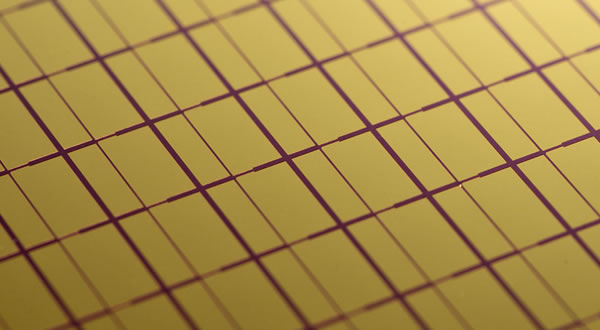

High precision processing technology

Heat spreaders used for optical communication are required to have high form accuracy of the order of magnitude of microns. Submounts for high-power lasers need to have sharp edges. A.L.M.T. owns a wide variety of machine tools, including machining centers and electric discharge machines, to carry out highly precise internal machining.

Highly precise machining operations

-

Our advanced machinery and technical experts, who possess in-depth knowledge of material properties, work together to produce complex shapes with a high degree of precision, up to the order of microns.

We have an array of machines and equipment capable of meeting customer requirements for both small and large-scale production within short delivery times.

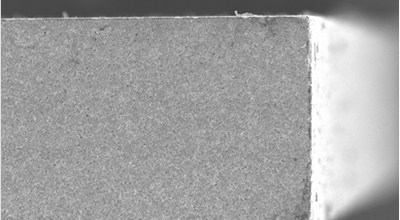

Sharp edge

-

We can create sharp edges on products made from Cu-W, Cu-Diamond, CVD diamond, and Sumicrystal. The standard edge radius is typically 30 μm or less, but we can achieve an edge radius of 20 μm or less based on the product specifications.

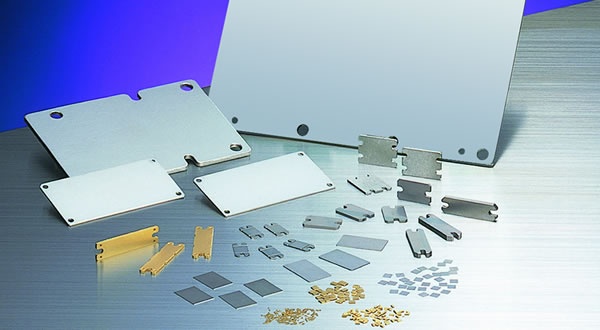

Heat spreaders for Electric and Hybrid Electric Vehicles

In Hybrid Electric Vehicles (HEVs), the inverter system plays a crucial role. It converts the direct current stored in the batteries into alternating current to run the motor and assist driving. When the vehicle decelerates, the inverter system reverses its operation. It converts the alternating current generated by the motor back into direct current and charges the batteries. Electric Vehicles operate with a similar inverter system, just without power generation by the engine.

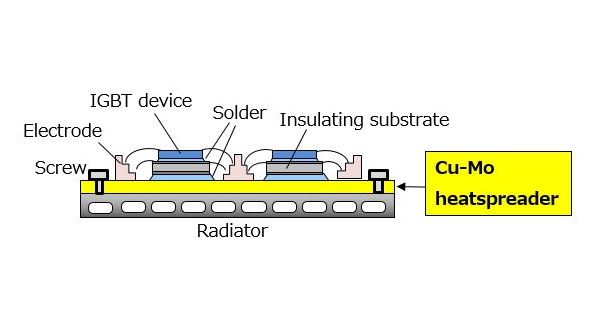

These inverters generally use a semiconductor device called the Insulated Gate Bipolar Transistor (IGBT). For the inverter system to operate stably in harsh environments such as in the engine bay, heat dissipation and thermal stress reduction are critical. Therefore, heat spreaders are employed for this purpose, with large-type heat spreaders like Cu-Mo (PCM35 and CPC232) being commonly used.

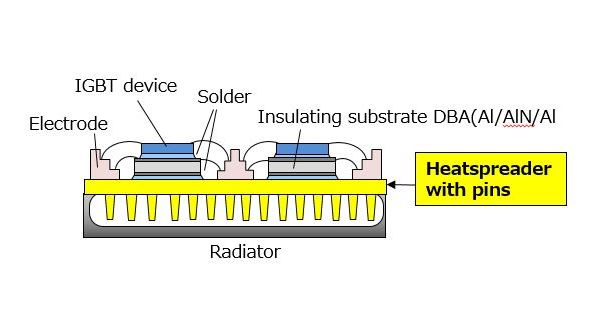

The ductility of Cu-Mo allows for cost-effective rolling and press-forming. It also allows for preemptive warping, which can help manage the final degree of warpage. The amount of Mo to be used can be minimized. Moreover, to further improve heat dissipation, a system has been developed that directly attaches pins to the heat dissipation plate at the bottom and incorporates them into the water-cooled radiator. This system uses a large Cu-Mo heat spreader with pins.

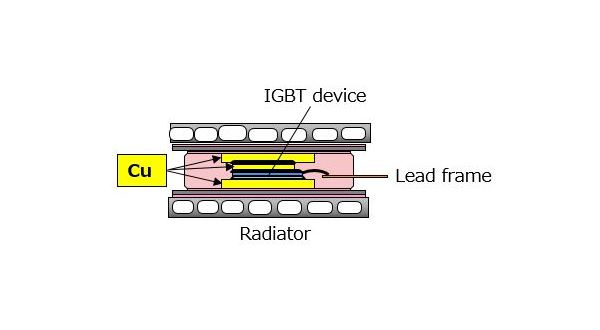

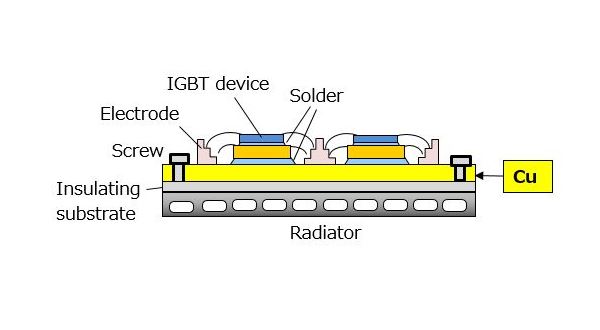

Single-sided heat dissipation system

(large-type heatspreader)

-

In this assembly process, the IGBT device is joined with an insulating substrate and large Cu-Mo heat spreader from top to bottom, with a water-cooled radiator installed beneath. By applying grease and fastening the large heat spreader, it ensures tight contact with the radiator to efficiently dissipate heat. The major advantage of this system is its ease of assembly and replacement.

Single-sided heat dissipation system (large-type heatspreader with pins)

-

To further improve heat dissipation, a system has developed that directly attaches pins to the bottom surface of the heat dissipation plate, integrating this with the water-cooled radiator. This system utilizes a large Cu-Mo heat spreader equipped with pins.

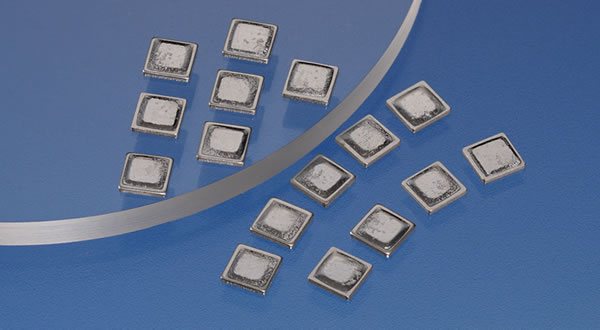

Single-sided heat dissipation system

(compact heatspreader)

-

Instead of a large Cu-Mo heat spreader, this system places a Cu-Mo heat spreader directly under the chips to ensure heat dissipation and thermal stress reduction.

Double-sided heat dissipation system

Next generation heat spreaders development

A high performance heat spreader is indispensable to achieve the design performance of the semiconductors being developed day by day. We continuously strive to develop new heat spreaders, catering to the specific requirements of each customer.

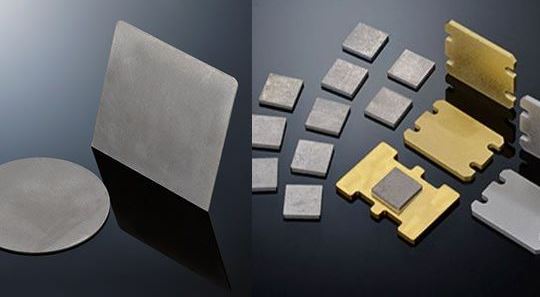

MAGSICTM (Mg-SiC composite) for electric railway IGBT

-

MAGSIC, which is manufactured from Mg ingot and SiC powder using our unique powder filling and infiltration technologies, is highly suitable for mass producing large-scale products. The standard MAGSIC material has a thermal expansion coefficient of 7.0 ppm and a thermal conductivity of 230 W/(m・K).

DMCH Ag-Diamond

-

Ag, which has a higher thermal conductivity than Cu, is the metal with the highest thermal conductivity. Ag and diamond powder are mixed and sintered using our proprietary technology to successfully produce a new material with a thermal conductivity of 600 W or more. This new material, which can be produced in larger dimensions than conventional diamond materials, serves as a diamond heat spreader. It can be used in a variety of applications including PKG base plates for high-output devices and heat dissipation substrates for large devices.

Heat spreader for mobile base stations (CPC™)

-

CPC is a composite material that features a laminated structure, with Cu layers sandwiching the Cu-Mo composite material. The thermal conductivity and linear expansion coefficient of this material can be adjusted by altering the composition of the core material, Cu-Mo, and the ratio of lamination. In addition, because both surfaces are composed of Cu, it exhibits excellent initial heat radiation.

"SEI Technical Review" published Technical data

The SEI Technical Review is a technical journal that features articles on the latest research and development efforts within the Sumitomo Electric Group.