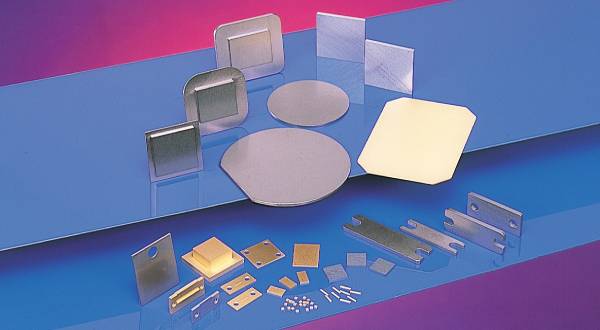

Heat spreader Materials

Pure metal

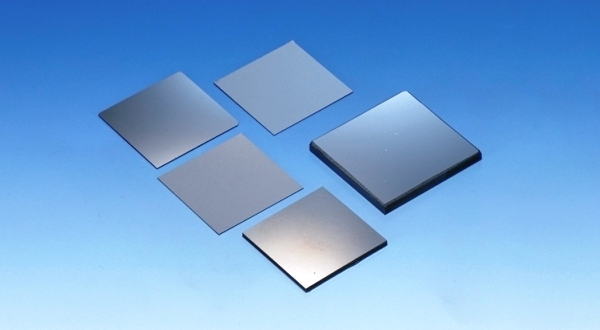

Mo (Molybdenum)

The materials have low thermal expansion close to Silicon (Si) chips, and exhibit superior mechanical properties. These heat spreaders are most suitable for high-power, high-reliability devices. Various machining processes, including stamping, are available for these materials.

| Applications | Diode, Thyristor, Power transistor substrate, LED substrate, etc. |

|---|

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃ [ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Mo | Mo | Mo | Its thermal expansion is similar to that of semiconductors such as Si, GaN, and SiC. As a result, it is widely used to reduce thermal stress on semiconductors. | 5.7 | 142 |

Alloy (Cu-W, Cu-Mo)

Cu-W (Copper-Tungsten)

Cu-W comprises Tungsten (W), known for its low thermal expansion, and Copper (Cu), recognized for its high thermal conductivity. Its thermal expansion can be adjusted to match that of surrounding materials such as Alumina and Kovar. Additionally, due to its good machinability, it can be used to manufacture small, complex-shaped parts. We offer six types of Cu-W (W-6, W-10, W-15, W-20, W-10T) to cater to customers' individual needs.

| Applications | Opto electronics, Wireless communication, LED substrate, etc. |

|---|

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃ [ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Cu-W | W-6 | 94W-6Cu | This Cu-W, with its low coefficient of thermal expansion, has a coefficient similar to that of GaAs and GaN. As a result, it prevents mismatches in thermal expansion. | 6.4 | 141 |

| W-10 | 89W-11Cu | Its coefficient of thermal expansion matches that of alumina. Therefore, it is widely used in alumina-based ceramic packages. | 7.9 | 174 | |

| W-15 * | 85W-15Cu | It has the same thermal expansion coefficient as beryllia ceramics, which are widely used in ceramic packages. This material is also frequently used for packages containing both alumina and kovar, as its thermal expansion coefficient sits midway between the coefficients of alumina and kovar. | 8.6 | 184 | |

| W-20 * | 80W-20Cu | This material matches the coefficient of thermal expansion of Kovar and is widely used in metal packages utilizing Kovar. | 9.8 | 200 | |

| W-10T | 89W-11Cu | Despite sharing the same thermal expansion coefficient as W-10, its thermal conductivity is enhanced through a special manufacturing method. Moreover, because it minimizes warping, it is widely used for sub-mount applications in high power lasers. | 7.9 | 205 |

* We have "T Grade", which has higher thermal conductivity.

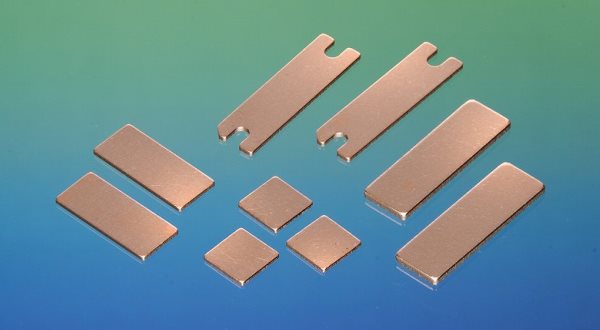

Cu-Mo (Copper-Molybdenum)

Cu-Mo can be processed using rolling and stamping methods. The thermal expansion and conductivity are easily adjustable. Furthermore, it exhibits excellent initial heat dissipation on the surface, as the laminated surface material, known as CPC, is made of pure copper. We offer 10 types of Cu-Mo (CM-15, CM-15K, PCM30, PCM35, PCM40, PCM60, CPC141, CPC232, CPC111, CPC212, CPC-300) to meet the diverse needs of our customers.

| Applications | Wireless communication, Opto electronics, in-vehicle, Wind power generation, LED, Industrial machine, etc. |

|---|

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃ [ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Cu-Mo | CM-15 | 85Mo-15Cu | This Cu-Mo has a low coefficient of thermal expansion and a coefficient close to that of GaAs and GaN. In turn, it prevents mismatches in thermal expansion. | 7.6 | 148 |

| CM-15K | 85Mo-15Cu | Improved thermal conductivity of normal 85Mo-15Cu by A.L.M.T. original technology. | 8.2 | 173 | |

| PCM30 | 70Mo-30Cu | This material maintains a low thermal expansion and can be produced using cost-effective processes such as rolling and stamping. | 7.5 | 195 | |

| PCM35 | 65Mo-35Cu | This material has a thermal expansion coefficient identical to that of alumina, making it widely used for alumina-based ceramic packaging. | 7.8 | 210 | |

| PCM40 | 60Mo-40Cu | As its thermal expansion coefficient is an intermediate value between the devices (Si, GaAs, GaN, SiC) and copper or aluminum, it is widely used as a stress cushioning material when devices are mounted on a copper or aluminum plate. | 8.2 | 220 | |

| PCM60 | 40Mo-60Cu | As its thermal expansion coefficient is an intermediate value between the devices (Si, GaAs, GaN, SiC) and copper or aluminum, it is widely used as a stress cushioning material when devices are mounted on a copper or aluminum plate. | 10.5 | 275 |

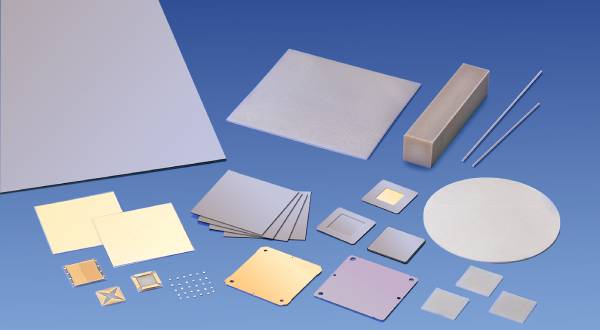

CPC™ (Copper, Copper-Molybdenum, Copper)

CPC is a laminated composite material that sandwiches a copper-molybdenum (Cu-Mo) layer between two copper layers. The thermal conductivity and coefficient of thermal expansion can be adjusted by altering the composition and lamination ratio of the Cu-Mo layer. In addition, because the outer layers of CPC are copper, it excels in initial heat dissipation.

| Applications | Wireless communication, Opto electronics, Automotive, Wind power generation, Industrial machine, etc. |

|---|

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| CPC™ | CPC141 | Cu/Cu-Mo/Cu | This material has a thermal expansion coefficient that matches that of alumina ceramic and is thus widely used in alumina-based ceramic packages. Since its surface is made of copper, which has high thermal conductivity, it exhibits excellent heat diffusion. | 7.6 | 200 |

| CPC232 | It is laminated in a "Cu:Cu-Mo:Cu=2:3:2(thickness)" ratio to adjust the coefficient of thermal expansion and thermal conductivity. | 8.4 | 235 | ||

| CPC111 | The material is laminated in a "Cu:Cu-Mo:Cu=1:1:1 (thickness)" pattern to adjust its coefficient of thermal expansion and thermal conductivity. | 9.8 | 260 | ||

| CPC212 | The material is laminated in a "Cu:Cu-Mo:Cu=2:1:2 (thickness)" pattern to improve its thermal conductivity to 300W/ (m・K). It is widely used for its contribution to the performance of high-power devices such as GaN and SiC. | 12.1 | 300 | ||

| CPC-300 | This material possesses a very high thermal conductivity, 300W/ (m・K), and is widely utilized to maximize the performance of high-power devices (GaN, SiC). We also offer thin plates with a thickness of 0.5mm. | 12.1 | 300 |

Ceramics

AlN (Aluminum Nitride)

AlN is a material with high electrical insulation and a low dielectric constant. On its surface, it is possible to form various metallized thin films suitable for electric circuits, chip mounting, and wire bonding.

| Applications | Semiconductor laser submount, LED substrate, etc. |

|---|

Scroll to view all

| Material | Trade Name / Composition |

Features | Coefficient of Average Linear Thermal Expansion R.T.~400℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|

| AlN | AlN(230W) | This material is useful when insulation and patterns are required. | 4.5 | 230 |

| AlN(200W) | 4.5 | 200 | ||

| AlN(170W) | 4.5 | 170 |

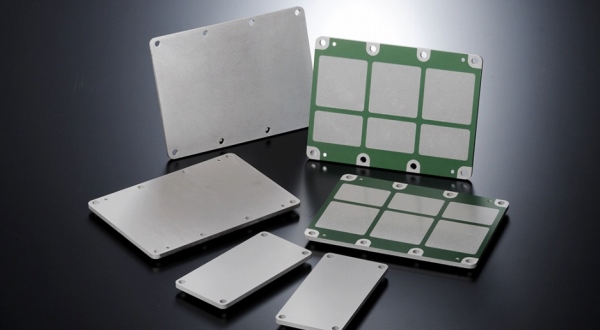

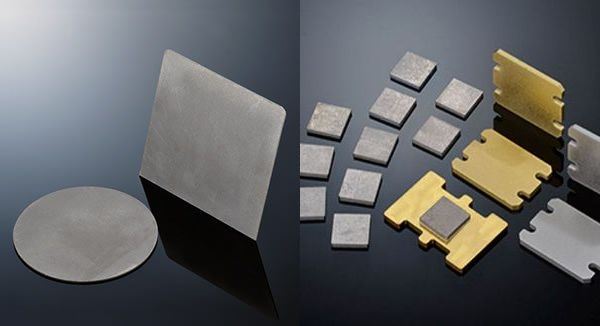

MAGSICTM (Magnesium-Silicon Carbide compsite material)

Standard materials are lightweight, with a low coefficient of thermal expansion (7.0 ppm) and high thermal conductivity (230 W/(m・K)). There is minimal warping, and the material maintains its shape well after heat-cycle testing.

| Applications | Power module for electric railway, industrial machinery and automotive (HEV), Wind power generation. |

|---|

Scroll to view all

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~120℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Mg-SiC | MAGSICTM | 18Mg-SiC | Since it is lightweight, it is suitable for use in larger sizes; in addition, it exhibits stable warpage, excellent high thermal conductivity, and heat dissipation. | 7.0 | 230 |

Diamond

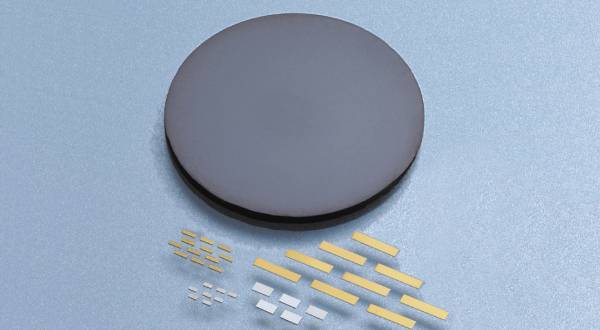

SUMICRYSTALTM

SUMICRYSTAL is a synthetic diamond single crystal with the highest thermal conductivity of all materials. Various metallized thin films for chip mounting and wire bonding can be formed on it.

| Applications | Semiconductor laser submount, etc. |

|---|

Scroll to view all

| Material | Features | Coefficient of Average Linear Thermal Expansion R.T.~100℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|

| SUMICRYSTALTM | This is a diamond heat spreader, which has the highest thermal conductivity of any substance. | 2.3 | 2,000 |

SUMICRYSTAL is a trademark of Sumitomo Electric Industries, Ltd.

CVD diamond (Chemical Vapor Deposition-Diamond)

CVD diamond is a single-crystalline diamond without a binder, obtained by the Chemical Vapor Deposition method (CVD). Various metallized thin films for chip mounting and wire bonding can be formed on it.

| Applications | Semiconductor laser submount, Power transistor substrate, etc. |

|---|

Scroll to view all

| Material | Features | Coefficient of Average Linear Thermal Expansion R.T.~100℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|

| CVD-Diamond | This is a diamond heat spreader, measuring 0.2 to 0.4 mm in thickness, produced by the CVD method (Chemical Vapor Deposition). | 2.3 | >1,000 |

Cu-Diamond (Copper-Diamond)

DMCH is a composite material of diamond and copper. Although its thermal expansion coefficient is similar to compound semiconductor materials like GaAs and GaN, DMCH has a higher thermal conductivity than copper. Various metallized thin films for chip mounting and wire bonding can be formed on it.

| Applications | Semiconductor laser submount, power transistor substrate, etc. |

|---|

Scroll to view all

| Material | Trade Name | Features | Coefficient of Average Linear Thermal Expansion R.T.~400℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|

| Cu-Diamond | DC60 | The heat spreader, which has high thermal conductivity, also possesses a coefficient of thermal expansion suitable for compound semiconductors such as GaAs and GaN. | 6.0 | 550 |

| DC70 | 6.5 | 500 |

Ag-Diamond (Silver-Diamond)

This is a composite material of Silver and Diamond, which has a thermal conductivity of 600W/(m・K), higher than that of Cu-Diamond. It can be used for large sizes up to 50×50mm.

| Applications | Wireless communication, Ceramics package, Power transistor substrate, MPU, etc. |

|---|

Scroll to view all

| Material | Trade Name | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃[ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|

| Ag-Diamond | AD90 | Its thermal conductivity is 600W/(m・K), which is higher than that of Cu-Diamond. It can be used for larger sizes up to 50×50mm. | 11.2 | 600 |