Next generation heatspreaders

Developing higher-performance heatspreaders

A high performance heatspreader is indispensable to activate semiconductor performances. We are now working on developing new heatspreaders to meet each customer's request .

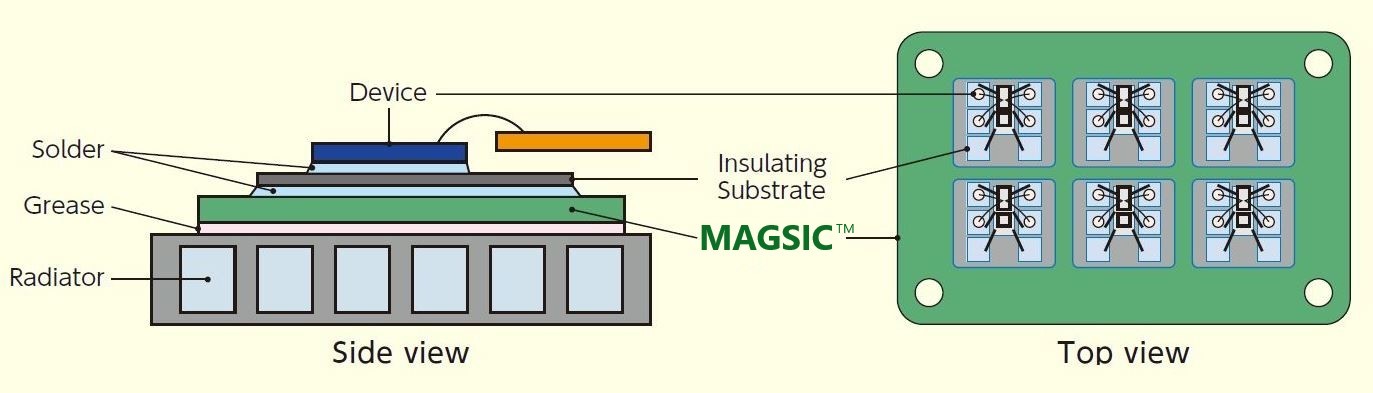

MAGSICTM for IGBT moduled used in electric railway

MAGSIC, manufactured from Mg ingot and SiC powder using our own forming and infiltration technologies, is suitable for mass production at large size.

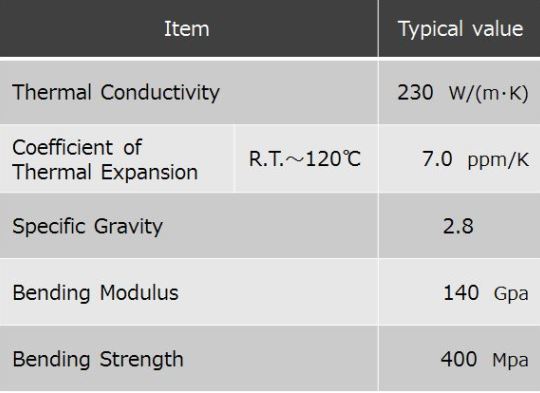

Standard MAGSIC material has thermal expansion of 7.0 ppm and thermal conductivity of 230 W/(m・K).

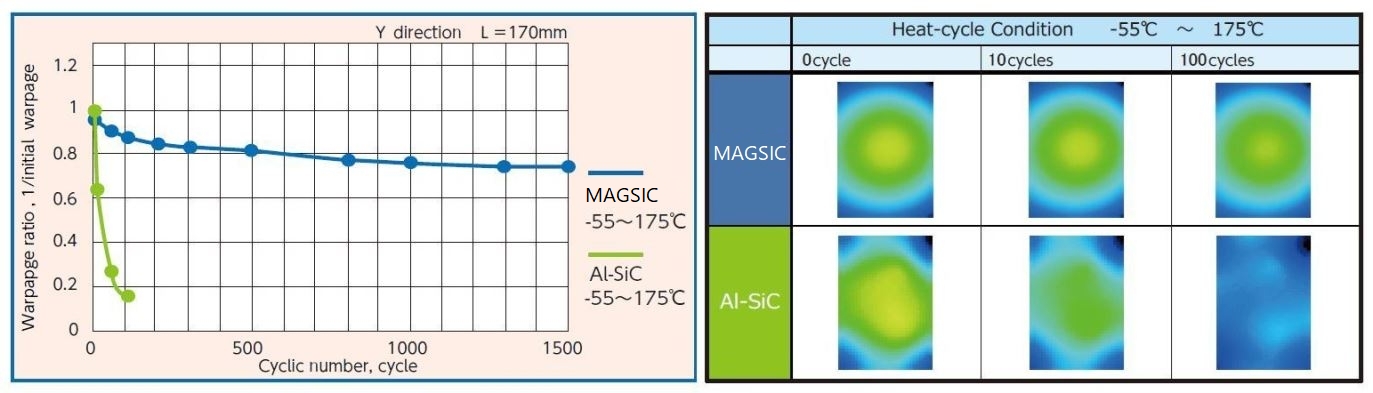

As it has small variations, its warped shape can be kept stable even after the heat cycle test.

- Features

-

- ■Higher thermal conductivity

- ■Better heat dissipation with excellent shape stability

- ■Lower specific gravity

- ■Light-weight

- ■Excellent in corrosion resistance to salt water

-

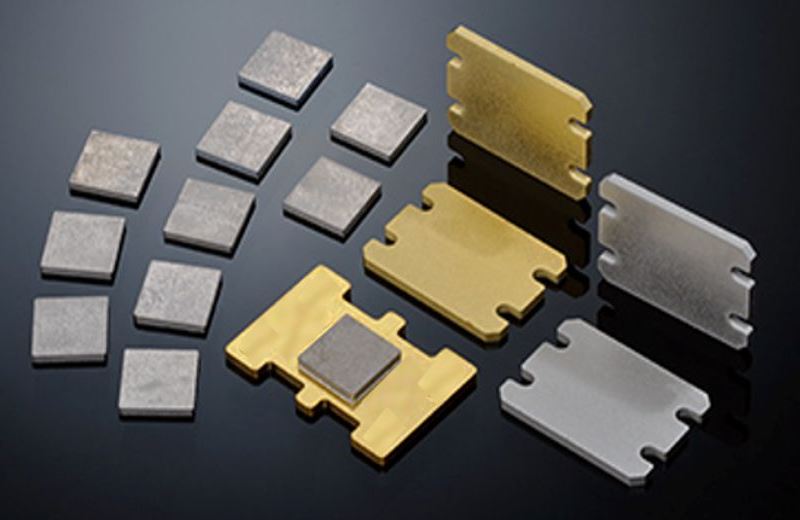

Application Example; IGBT Module

-

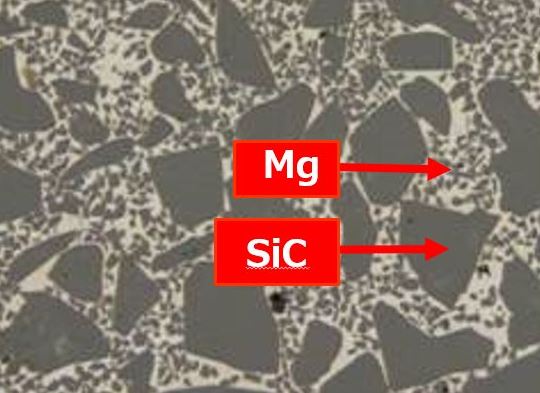

Microstructure

-

Warpage Behaivior by Heat-cycle

-

Properties (Typical)

Ag-Diamond for power devices

This new material, allowing us to manufacture materials larger than the conventional materials, can be used for various applications including PKG base plates for large output and heat dissipation substrate for large-size devices.

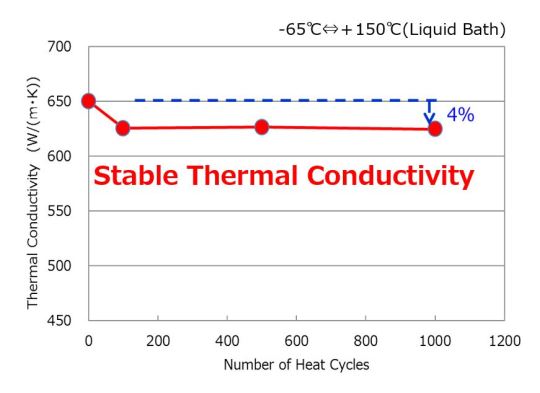

In addition, it provides a lower decrease in thermal conductivity even after high-temperature treatment at 800℃ or cold heat tests.

Furthermore, this new material will be able to assemble to other parts with Ag-Brazing.

- Features

-

- ■Thermal conductivity (TC) is more than 600W/(m・K)

- ■Stable TC for heat-cycle.

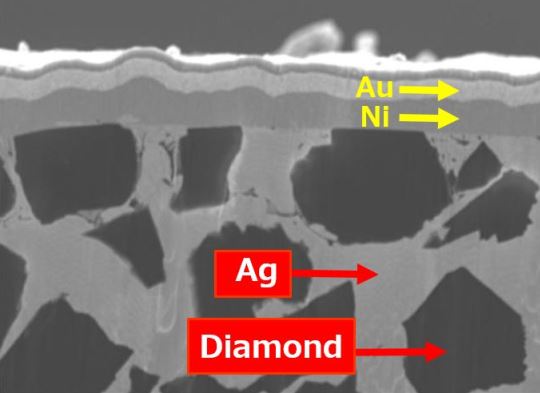

- ■Ni and Ni/Au plating are available.

- ■Ag-Brazing (780℃) is available.

-

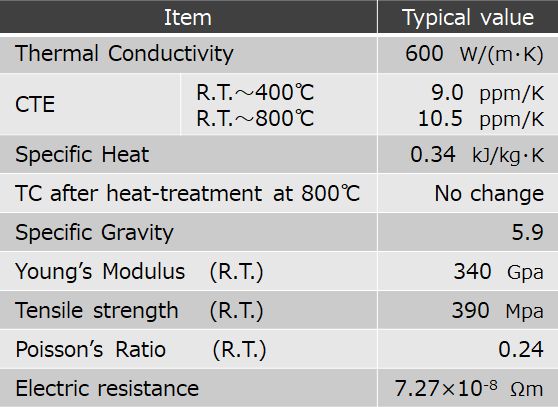

Properties(Typical)

-

Influence on Heat-cycle of TC

-

Microstructure

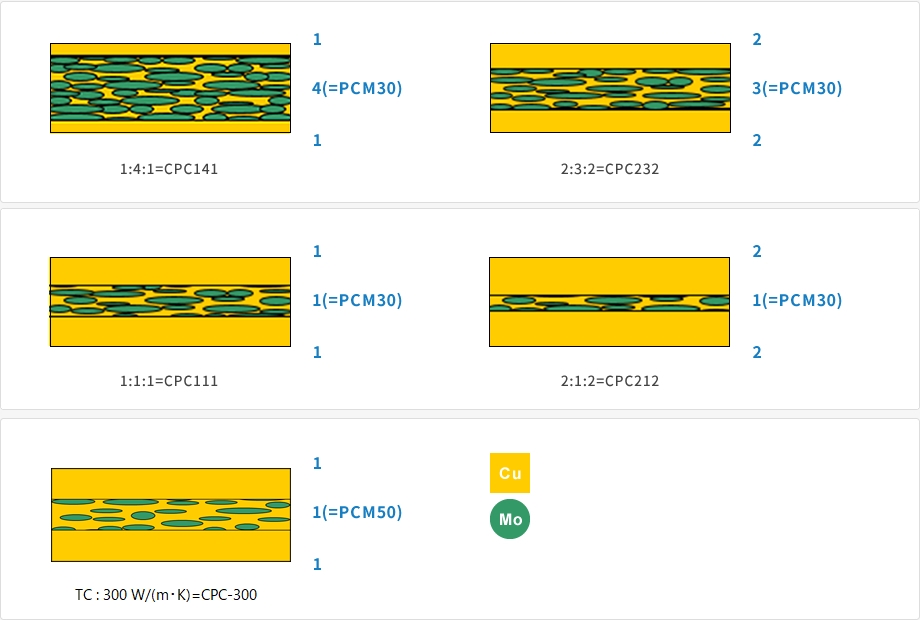

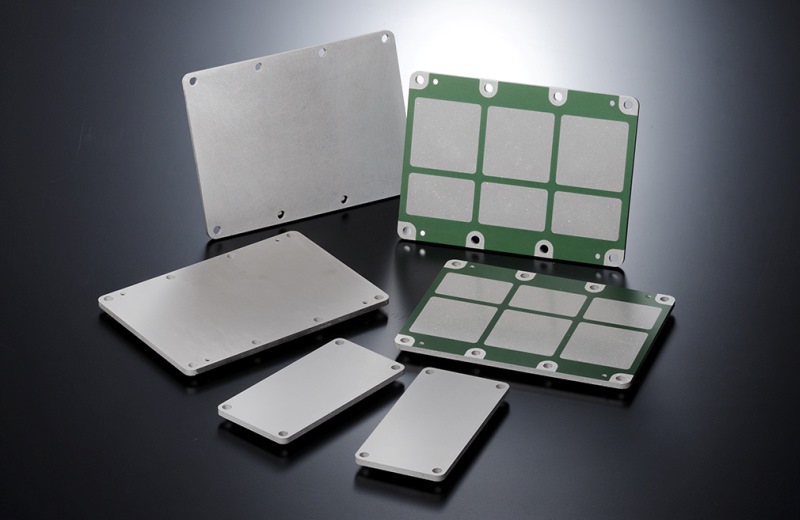

CPC™ for cell base stations

CPC(copper, copper-molybdenum, copper) is a composite material with a laminated structure with cooper-molybdenum (Cu-Mo) sadwitched between copper layers. Thermal conductivity and coefficient of thermal expansion can be adjusted by changing composition and lamination ratio of Cu-Mo.

In addition, as both surfaces are copper, the initial heat dissipation effect is excellent.

It is mainly used for amplifier substrates of cell base stations in wireless communications fields.