Tungsten carbide powder

Tungsten carbide powder

We manufacture tungsten carbide powder (WC) used for various applications such as cemented carbide, cermet, diamond tools, electric contact under strict quality control.

To see the whole table, scroll sideways.

| Type | Particle size(μm) | WC(%) | TC(%) | FC(%) | Fe(%) | Mo(%) | NVR(%) |

|---|---|---|---|---|---|---|---|

| WC06 | 0.5 to 0.6 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC07 | 0.6 to 0.7 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC08 | 0.7 to 0.9 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC10 | 0.9 to 1.1 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

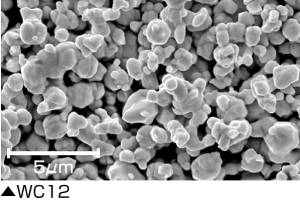

| WC12 | 1.1 to 1.3 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC15 | 1.3 to 1.8 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC20 | 1.8 to 2.2 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC25 | 2.2 to 2.8 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC30 | 2.8 to 3.3 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC35 | 3.3 to 3.8 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC40 | 3.7 to 4.4 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC45 | 4.2 to 5.0 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC50 | 4.7 to 5.5 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC60 | 5.5 to 7.1 | ≥99.8 | 6.13±0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.01 |

Particle size is the average grain diameter by the Fischer method. For T.C, we respond to your requests beyond those listed above. WC is the remainder obtained by subtracting F.C, Fe, Mo and NVR from 100.

*TC:Total Carbon

*FC:Free Carbon

*NVR:Nonvolatile content

Low volume tungsten carbide powder

We manufacture tungsten carbide powder with much lower volume than conventional one.

The powder can also lower alloy shrinkage, and raise productivity according to various applications.

To see the whole table, scroll sideways.

| Type | Particle size(μm) | TC(%) | FC(%) | Fe(%) | Mo(%) | Cr(%) |

|---|---|---|---|---|---|---|

| WC05LV | ― | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ― |

| WC06LV | 0.5 to 0.7 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ― |

| WC08LV | 0.7 to 0.9 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ― |

| WC10LV | 0.9 to 1.1 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ― |

| WCR05LV | ― | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | 0.80 to 0.90 |

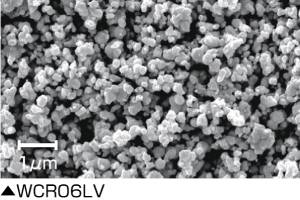

| WCR06LV | 0.5 to 0.7 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | 0.80 to 0.90 |

| WCR07LV | 0.7 to 0.9 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | 0.80 to 0.90 |

- Expected effects

- Lower shrinkage during sintering the pressed powder. (commonalizing molds with tungsten carbide powder with different grain size)

- Possible to reduce molding pressure. ( preventing cracks in pressed body with complex shape)

- Possible to upsize sintered body.

- Possible to sinter the powder more efficiently per batch. (improving productivity in mixing process)

- Possible to reduce mixing time.

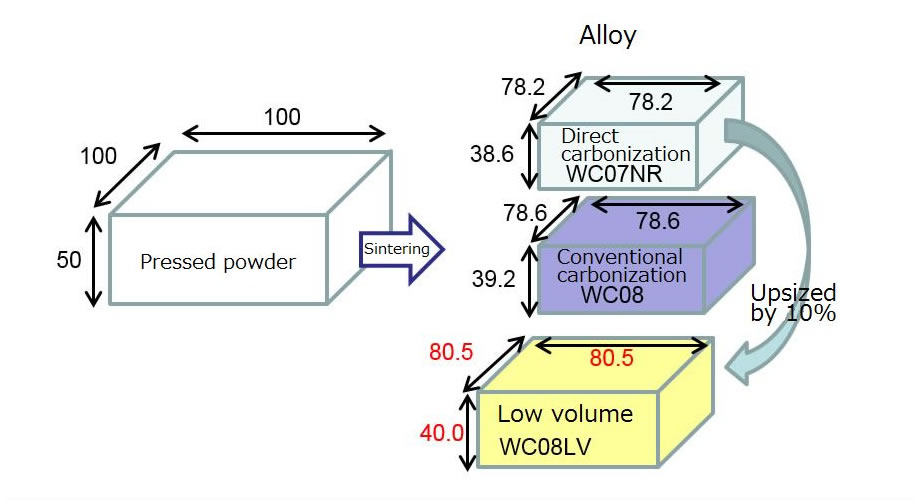

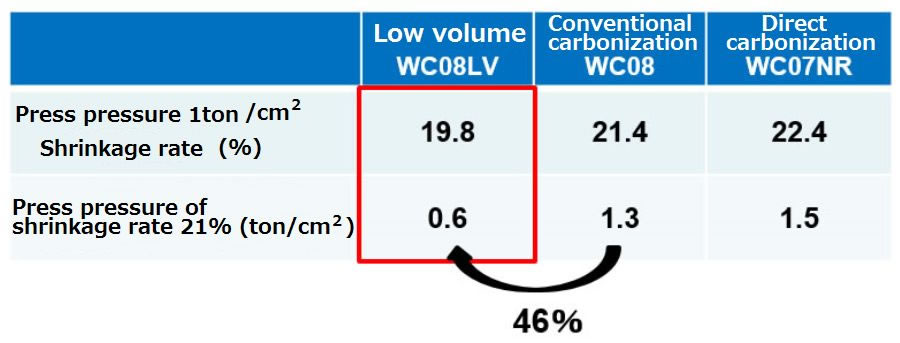

Upsizing sintered body. Comparison with 0.8 µm tungsten carbide powder

Reducing molding pressure

Low volume and fine tungsten carbide powder (with grain growth inhibitor)

To see the whole table, scroll sideways.

| Type | Particle size (μm) | TC(%) | FC(% | Fe(%) | Mo(%) | Cr(%) |

|---|---|---|---|---|---|---|

| WCR05P | 0.45 to 0.54 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | 0.80 to 0.90 |

| WCR06P | 0.55 to 0.65 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | 0.80 to 0.90 |

| WCR07P | 0.66 to 0.80 | 6.13±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | 0.80 to 0.90 |

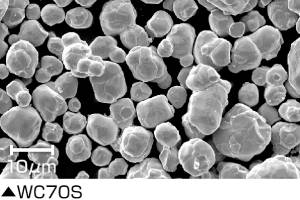

Uniform tungsten carbide powder for shock resistant tools

We manufacture a uniform tungsten carbide powder with narrow grain size distribution and high strength by carbonizing tungsten powder at higher temperatures.

To see the whole table, scroll sideways.

| Type | Particle size (μm) | WC(%) | TC(%) | FC(%) | Fe(%) | Mo(%) | NVR(%) |

|---|---|---|---|---|---|---|---|

| WC25S | 2.4 to 3.2 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC30S | 2.5 to 3.5 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC35S | 3.2 to 3.8 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC40S | 4.0 to 5.0 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC45S | 4.5 to 5.5 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC50S | 5.2 to 5.8 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC60S | 6.0 to 7.0 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC70S | 7.0 to 8.0 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC80S | 8.0 to 10.0 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

| WC100S | 14 to 16 | ≥99.8 | 6.15±0.05 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.01 |

Particle size is the average grain diameter by the Fischer method. For T.C, we respond to your requests beyond those listed above. WC is the remainder obtained by subtracting F.C, Fe, Mo and NVR from 100.

*NVR:Nonvolatile content

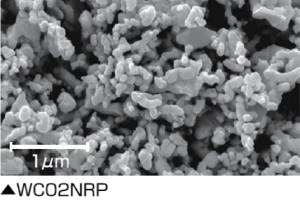

Ultrafine tungsten carbide powder

We manufacture ultrafine tungsten carbide powder with grain size of up to about 0.1 μm by direct carbonization reaction of tungsten oxide and carbon powder. This powder is suitable for various applications such as raw materials for drills and end mills used for printed circuit boards, as well as binder-less alloy, which require high hardness and high strength.

Ultrafine tungsten carbide powder (Standard powder)

To see the whole table, scroll sideways.

| Type | Particle size(μm) | TC(%) | FC(%) | Fe(%) | Mo(%) | Cr(%) |

|---|---|---|---|---|---|---|

| WC02NR | * 0.10 to 0.14 | 6.10 to 6.25 | ≤0.25 | ≤0.02 | ≤0.02 | ― |

| WC04NR | 0.45 to 0.49 | 6.15±0.05 | ≤0.20 | ≤0.02 | ≤0.02 | ― |

| WC02N | * 0.10 to 0.13 | 6.20±0.05 | ≤0.20 | ≤0.02 | ≤0.02 | 0.80 to 0.90 |

| WC04N | 0.45 to 0.49 | 6.20±0.05 | ≤0.15 | ≤0.02 | ≤0.02 | 0.80 to 0.90 |

| WC05N | 0.50 to 0.55 | 6.20±0.05 | ≤0.15 | ≤0.02 | ≤0.02 | 0.80 to 0.90 |

Particle size is the average grain diameter by the Fischer method.

* indicates the converted grain diameter by the BET method.

Ultrafine tungsten carbide powder (Uniform powder)

To see the whole table, scroll sideways.

| Type | Particle size (μm) | TC(%) | FC(%) | Fe(%) | Mo(%) | Cr(%) |

|---|---|---|---|---|---|---|

| WC02NRP | * 0.10 to 0.14 | 6.10 to 6.25 | ≤0.25 | ≤0.02 | ≤0.02 | ― |

| WC04NRP | 0.45 to 0.49 | 6.15±0.05 | ≤0.20 | ≤0.02 | ≤0.02 | ― |

| WC02NP | * 0.10 to 0.13 | 6.20±0.05 | ≤0.20 | ≤0.02 | ≤0.02 | 0.80 to 0.90 |

| WC04NP | 0.45 to 0.49 | 6.20±0.05 | ≤0.15 | ≤0.02 | ≤0.02 | 0.80 to 0.90 |

| WC05NP | 0.50 to 0.55 | 6.20±0.05 | ≤0.15 | ≤0.02 | ≤0.02 | 0.80 to 0.90 |

Paricle size is the average grain diameter by the Fischer method.

* indicates the converted grain diameter by the BET method.

- Tungsten Technical information