Tungsten powder

Tungsten powder

Tungsten powder is manufactured under strict quality control and used for high specific gravity material, diamond tools, metallizing material, sintered parts. Furthermore, we have fine tungsten powder.

Tungsten powder

To see the whole table, scroll sideways.

| Type | Particle size(μm) | W(%) | O(%) | Fe(%) | Mo(%) | NVR(%) |

|---|---|---|---|---|---|---|

| A30 | 0.6 to 0.8 | ≥99.9 | ≤0.60 | ≤0.02 | ≤0.02 | ≤0.01 |

| B10 | 1.0 to 1.3 | ≥99.9 | ≤0.40 | ≤0.02 | ≤0.02 | ≤0.01 |

| B20 | 1.0 to 1.5 | ≥99.9 | ≤0.20 | ≤0.02 | ≤0.02 | ≤0.01 |

| B30 | 1.4 to 1.7 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| C10 | 1.7 to 2.0 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| C20 | 1.9 to 2.2 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| C30 | 2.1 to 2.5 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| C40 | 2.3 to 2.8 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| C50 | 2.8 to 3.4 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| C60 | 3.1 to 3.6 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| D10 | 3.6 to 4.4 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| D20 | 4.5 to 7.5 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| D100 | 7.6 to 12.0 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| D150 | 12.1 to 17.0 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| Coarse grain | 23 to 28 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

Particle size is the average grain diameter by the Fischer method. NVR is the remainder after heating in hydrogen chloride stream.

W is the remainder obtained by subtracting Fe, Mo and NVR from 100.

*NVR: Nonvolatile content

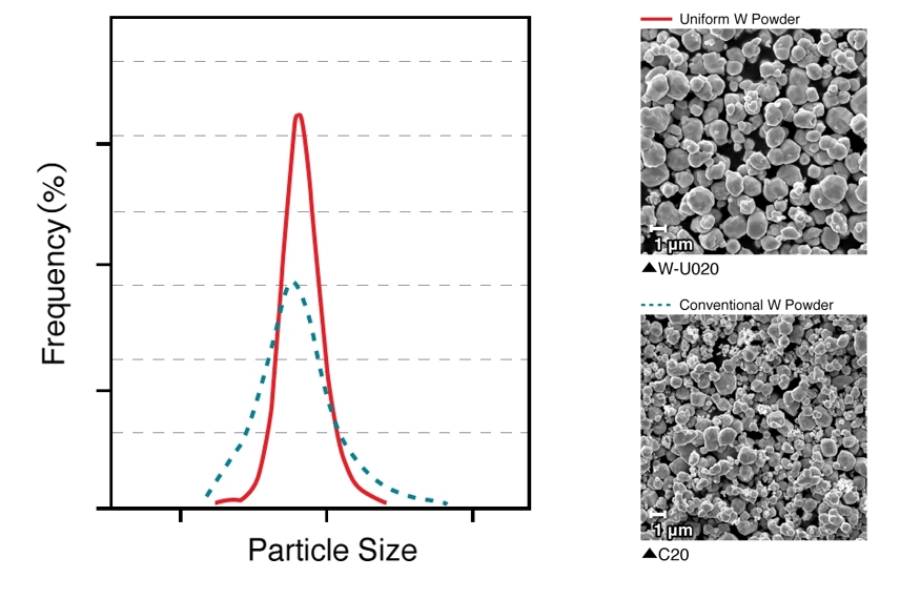

Uniform tungsten powder

Using our unique technology, we developed tungsten powder with more uniform grains than conventional products. Beyond improved handling performance by the low-volumed powder, it is possible to form a uniform powder layer. Moreover, layer thickness and shrinkage during sintering can be controlled.

To see the whole table, scroll sideways.

| Type | Particle size(μm) | W(%) | O(%) | Fe(%) | Mo(%) | NVR(%) |

|---|---|---|---|---|---|---|

| W-U010 | 0.9 to 1.4 | ≥99.9 | ≤0.20 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U020 | 1.5 to 2.4 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U030 | 2.5 to 3.4 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U040 | 3.5 to 4.4 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U050 | 4.5 to 5.4 | ≥99.9 | ≤0.15 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U100 | 8.0 to 12.0 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U150 | 13.0 to 17.0 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U200 | 18 to 22 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

| W-U250 | 23 to 28 | ≥99.9 | ≤0.10 | ≤0.02 | ≤0.02 | ≤0.01 |

Paticle distribution of uniform tungsten powder

High purity tungsten powder

With outstanding purification technology and strict environmental management, we manufacture high purity tungsten powder with extremely few radioactive elements and alkali metals.

4N-W

To see the whole table, scroll sideways.

| Type | W(%) | Na(ppm) | K(ppm) |

|---|---|---|---|

| 4N-W | ≥99.99 | ≤10 | ≤10 |

| Analysis example | ≥99.99 | 5 | 3 |

* Parricle size ranges form 1.0 to 5.0 μm to meet your request.

5N-W

To see the whole table, scroll sideways.

| Type | W(%) | Na(ppm) | K(ppm) | U(ppb) | Th(ppb) |

|---|---|---|---|---|---|

| 5N-W | ≥99.999 | ≤1 | ≤1 | ≤1 | ≤1 |

| Analysis example | ≥99.999 | 0.08 | 0.04 | 0.2 | 0.5 |

* Grain size ranges from 1.0 μm to 5.0 μm to meet your requests.

- Tungsten Technical information