ホーム > HOME > Product Information > Heat spreader materials Top > Heat spreader for Semiconductor Devices 202206

Heat spreader

Dissipate the Heat of Your Semiconductor Device!

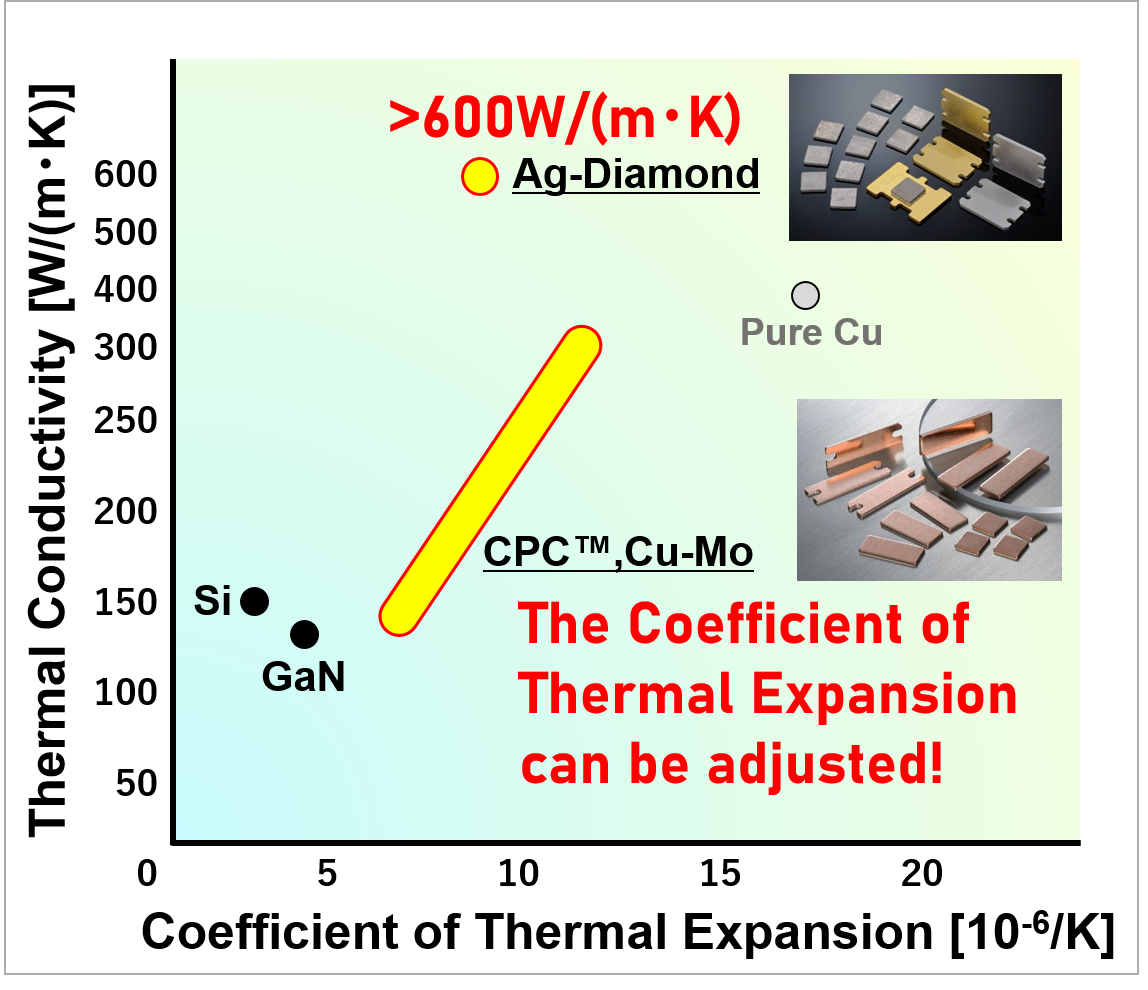

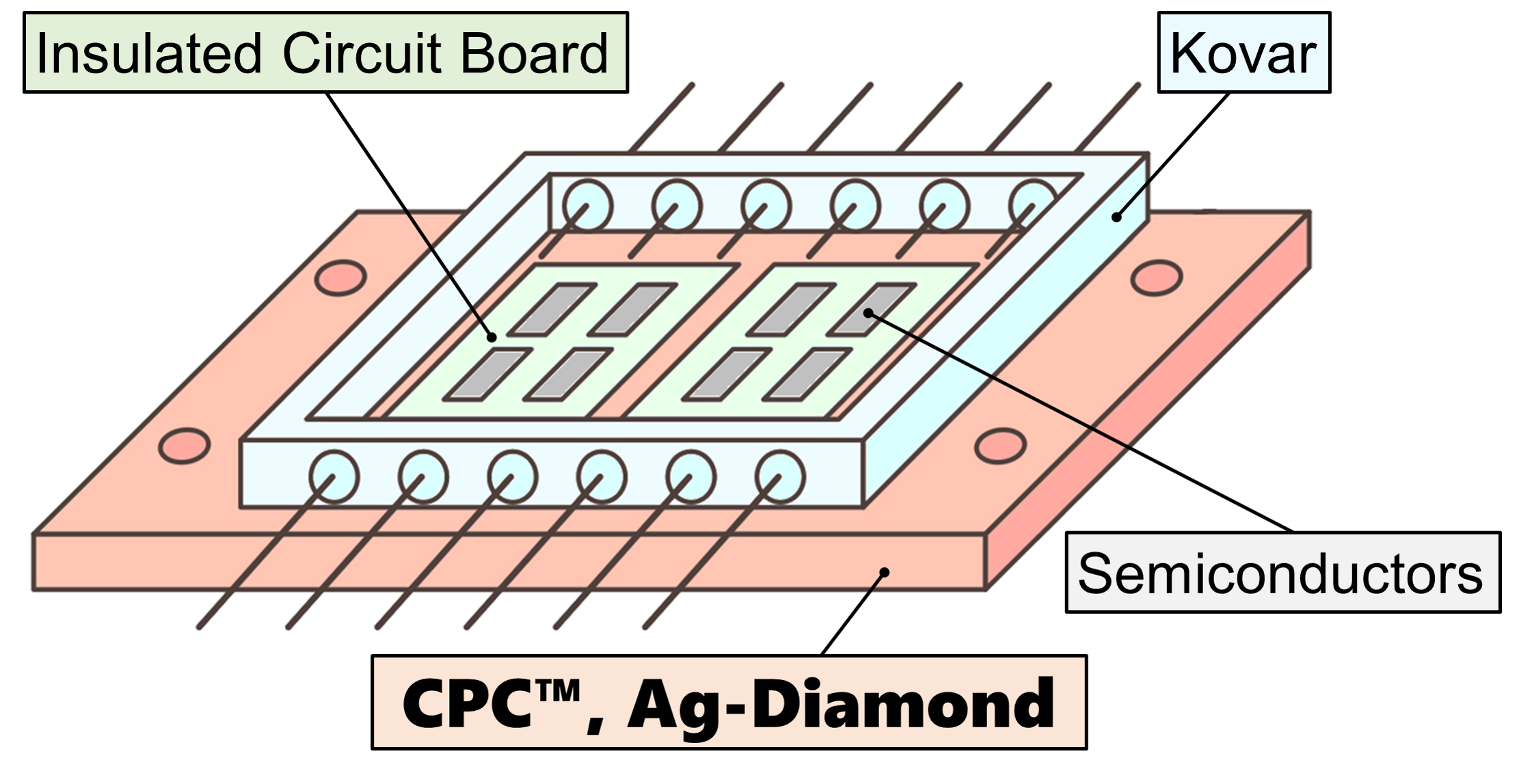

CPC™(Copper / Copper-Molybdenum / Copper)

- High thermal conductivity.- Coefficient of thermal expansion is adjustable and can be matched with surrounding materials.

- Laminated material "Cu / Cu-Mo / Cu".

- The Cu layer enhances the initial heat dissipation.

- High mass-productivity by rolling and pressing process.

Ag-Diamond(Silver-Diamond)

- High thermal conductivity, 600 W/(m・K).

- The thermal expansion is close to semiconductor chips and ceramic materials.

The information mentioned here is very limited.

Click the buttons below for detailed information or inquiry.

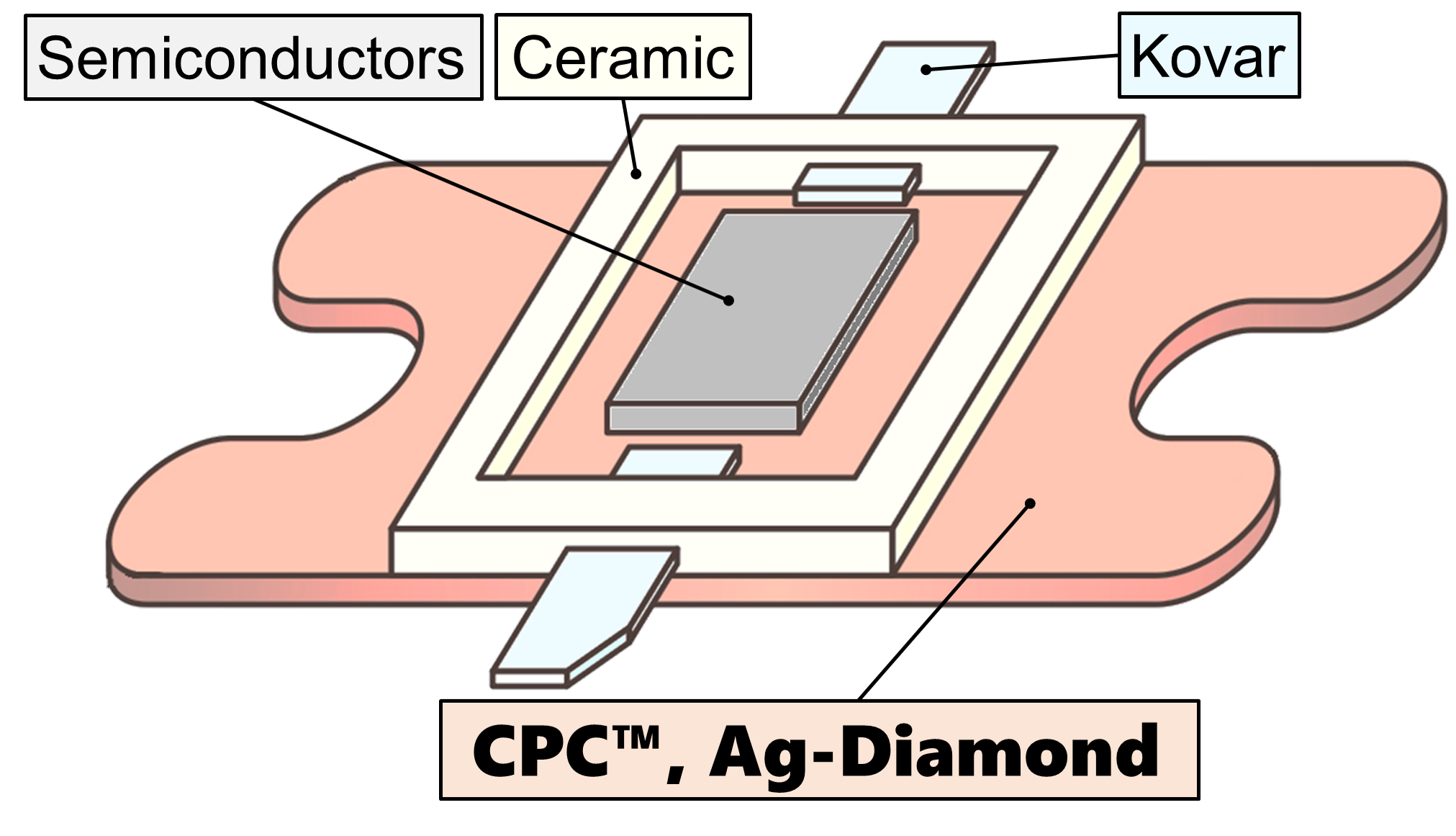

For Ceramic Package

CPC™ heatspreader

- By changing the content ratio of Cu, the coefficient of thermal expansion can be adjusted close toceramic frames.

So, it can relieve heat stress between a device and a substrate.

Ag-Diamond heatspreader

- Higher thermal conductivity, >600W/(m・K)- A coefficient of thermal expansion (CTE) is close to ceramic frames.

Click the buttons below for detailed information or inquiry.

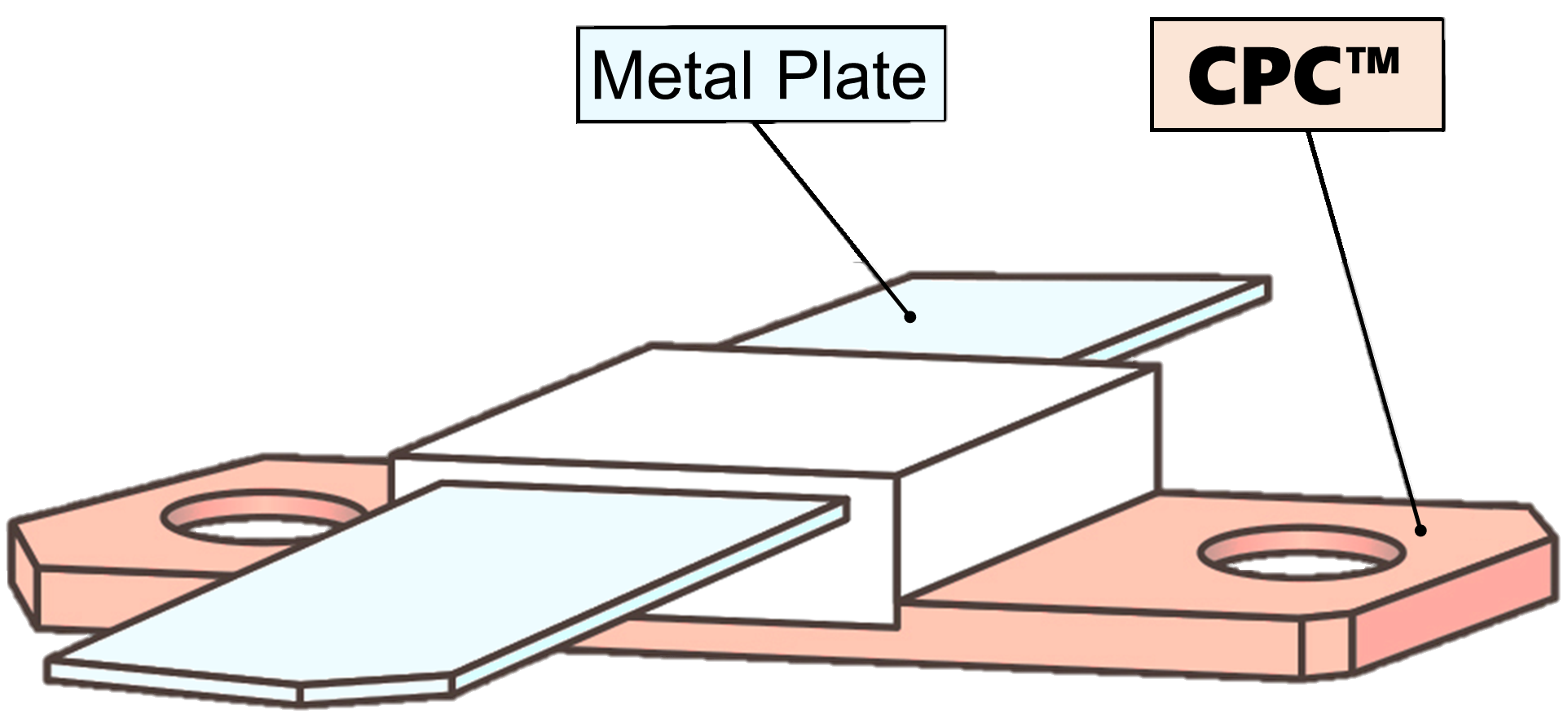

For Metal Package

CPC™ heatspreader

- By changing the content ratio of Cu, the coefficient of thermal expansion can be adjusted close tometallic frames such as Kovar.

So, it can improve the reliability of package.

Ag-Diamond heatspreader

- Higher thermal conductivity, >600W/(m・K)- This material is used in the high-end applications.

Click the buttons below for detailed information or inquiry

For Plastic Package

CPC™ heatspreader

- By reducing the content ratio of Cu, the coefficient of thermal expansion can be adjusted close tosemiconductor materials.

So, it can improve the reliability of devices.

Click the buttons below for detailed information or inquiry.