Molybdenum powder

Molybdenum powder

Processing reduction of molybdenum powder ourselves, we can respond quickly to customers’ quality requiests.

3N-Mo powder is highly pure with grain size 0.8 μm to 6.0 μm, using high quality Mo raw material under strict controlled production.

4N-Mo powder is manufactured by Mo raw material with purity of 99.99% or above. The manufacturing process is strictly controlled too, thus preventing contamination of metallic impurities such as Fe and Ni.

In addition, we offer the specific product you request, such as low oxygen low volume powder with high packinig density and less shrinkage during pressing.

3N-Mo powder

To see the whole table, scroll sideways.

| Type | Particle size (μm) | O(%) | Fe(%) | NVR(%) | Mo(%) |

|---|---|---|---|---|---|

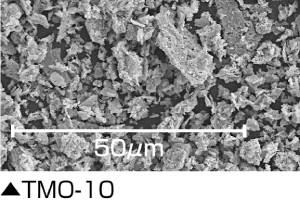

| TMO-10 | 0.8 to 1.7 | ≤1.0 | ≤0.01 | ≤0.1 | ≥99.9 |

| TMO-20 | 1.8 to 2.7 | ≤1.0 | ≤0.01 | ≤0.1 | ≥99.9 |

| TMO-30 | 2.8 to 3.7 | ≤0.1 | ≤0.01 | ≤0.1 | ≥99.9 |

| TMO-40 | 3.8 to 4.7 | ≤0.1 | ≤0.01 | ≤0.01 | ≥99.98 |

| TMO-50 | 4.8 to 6.0 | ≤0.1 | ≤0.01 | ≤0.01 | ≥99.98 |

Mo is the remainder obtained by subtracting Fe and NVR from 100.

4N-Mo powder

To see the whole table, scroll sideways.

| Type | Particle size(μm) | O(%) | Mo(%) |

|---|---|---|---|

| 4N-Mo | 3.5 to 5.5 | ≤0.1 | ≥99.99 |

Mo is the remainder obtained by subtracting the 13 elements in the Table below from 100.

To see the whole table, scroll sideways.

| Elements | Al(ppm) | Ca(ppm) | Cr(ppm) | Cu(ppm) | Fe(ppm) | Mg(ppm) | Mn(ppm) | Ni(ppm) | Pb(ppm) | Si(ppm) | Sn(ppm) | Na(ppm) | K(ppm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Analysis example | <5 | <1 | 2 | 1 | 8 | <1 | <1 | 5 | <5 | <10 | <3 | 5 | 35 |

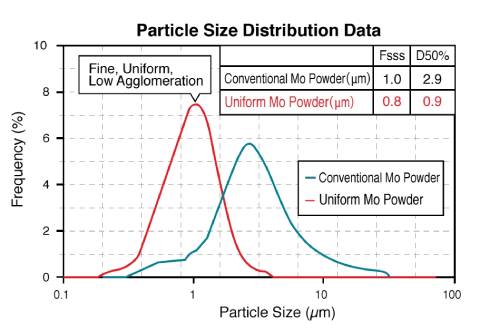

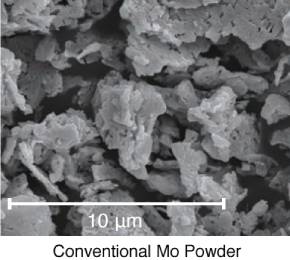

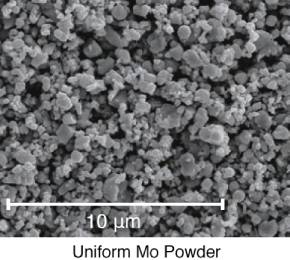

Lineup of uniform powder for metallization or other applications

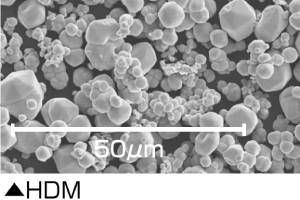

High density molybdenum powder

High density molybdenum power features high packing density, small shrinkage during pressing and few gas component elements. These features make it ideal for ceramic packaging, metallization and sputtering targets.

| Standard value | Analysis example | |

|---|---|---|

| Particle size(μm) | ≥4.0 | 5.0 |

| Mo(%) | ≥99.95 | ≥99.95 |

| O(%) | ≤0.15 | 0.05 |

| Fe (%) | ≤0.015 | 0.006 |

| NVR (%) | ≤0.05 | 0.003 |

| FV (cm3/100g) | ≤47 | 39 |

| TV (cm3/100g) | ≤22 | 19.4 |

Mo is the remainder obtained by subtracting Fe and NVR from 100.

Trioxide molybdenum powder

Molybdenum oxide used for pigment, coloring and catalyst

High purity trioxide molybdenum powder

To see the whole table, scroll sideways.

| Type | Al(ppm) | Ca(ppm) | Cr(ppm) | Cu(ppm) | Fe(ppm) | Mg(ppm) | Mn(ppm) | Ni(ppm) | Pb(ppm) | Si(ppm) | Sn(ppm) | Grain size(µm) | IL(%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MoO3-1 | ≤15 | ≤15 | ≤10 | ≤15 | ≤15 | ≤10 | ≤10 | ≤10 | ≤5 | ≤15 | ≤15 | 10 to 20 | ≤0.3 |

| MoO3-2 | ≤20 | ≤15 | ≤10 | ≤10 | ≤30 | ≤20 | ≤10 | ≤10 | ≤30 | ≤140 | ≤55 | 1 to 5 | ≤0.6 |

We respond to consultation on production of intermediate (lower grade) oxides other than those listed above.

- Molybdenum Technical information