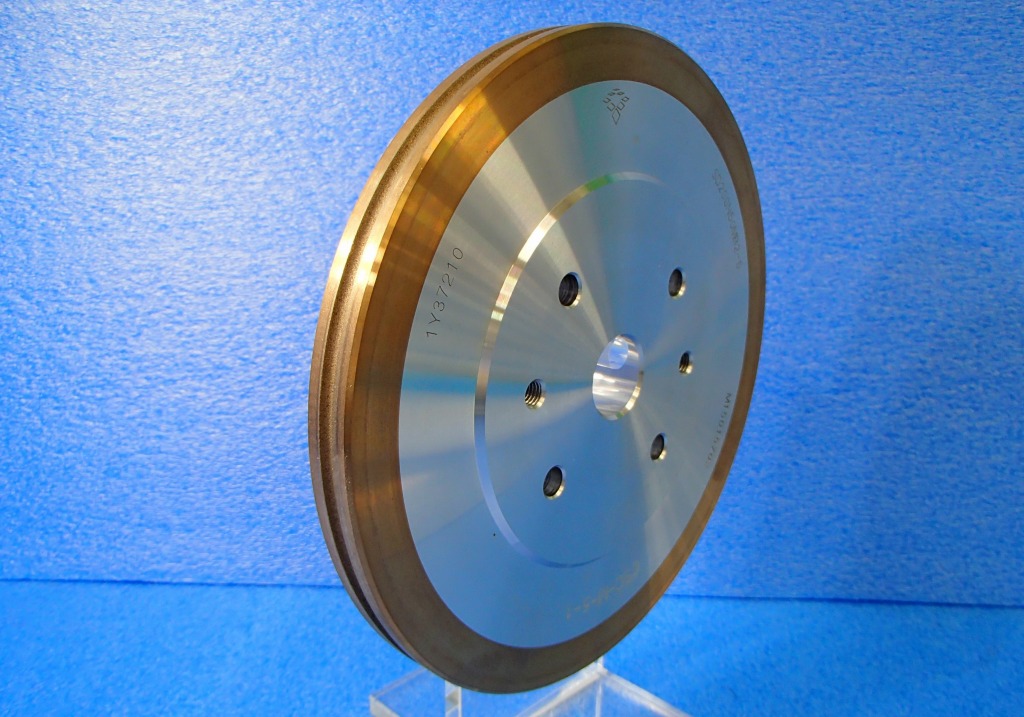

Metal bond wheels

12件中/1-12件目を表示

The employment of high grain holding power specific to metal bond and grain layer structure suitable for electro-discharge truing realizes high precision and high efficiency truing.

| Applications | Work: pump parts for air conditioners, oil pump parts for cars, engine parts for cars |

|---|

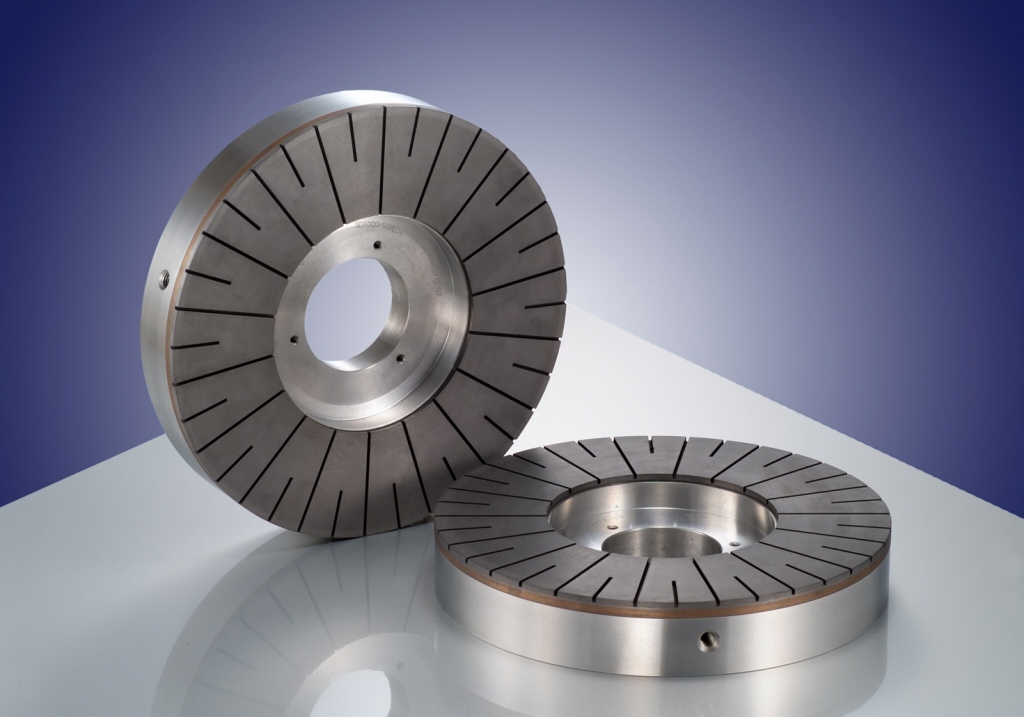

The "fine blade metal bond type" is a large-size thin blade wheel developed for purposes of precision cutting and grooving. Since this type has high blade thickness accuracy and run-out accuracy, it is ideal for processing of precision molds of cemented carbide and ceramics.

| Applications | Grooving and cutting of carbide and ceramics precision molds, precision grooving and cutting of ferrite parts of magnetic materials |

|---|

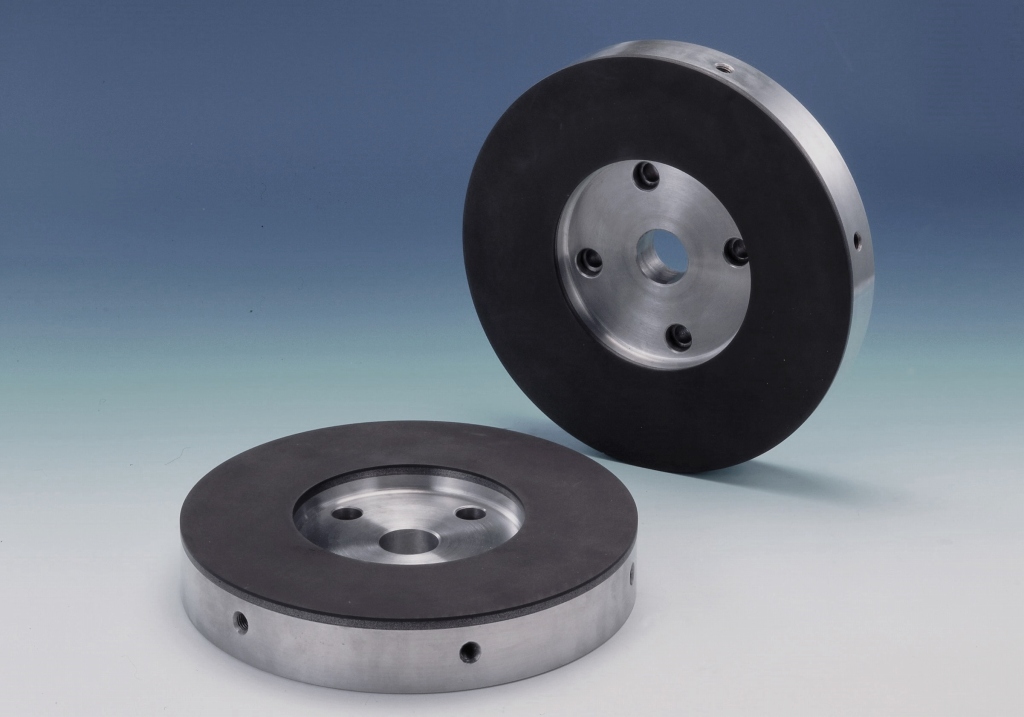

Long-lasting sharpness and high dressing performance improve the grinding efficiency significantly.

| Applications | Mass production of double-ended surface grinding of magnetic material parts and ceramics parts etc. |

|---|

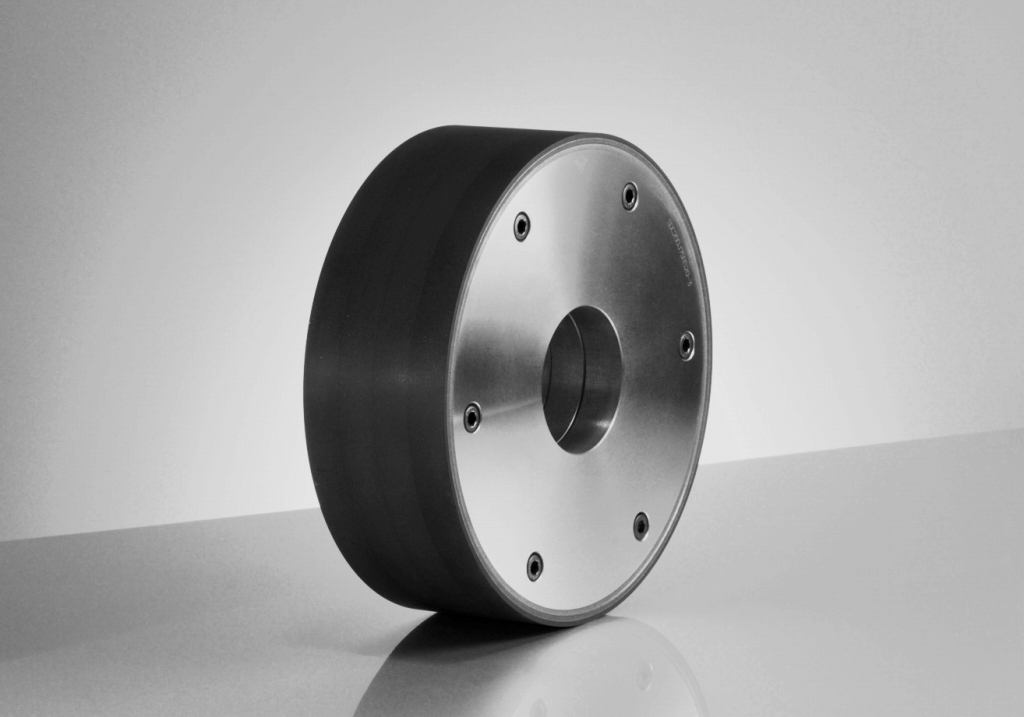

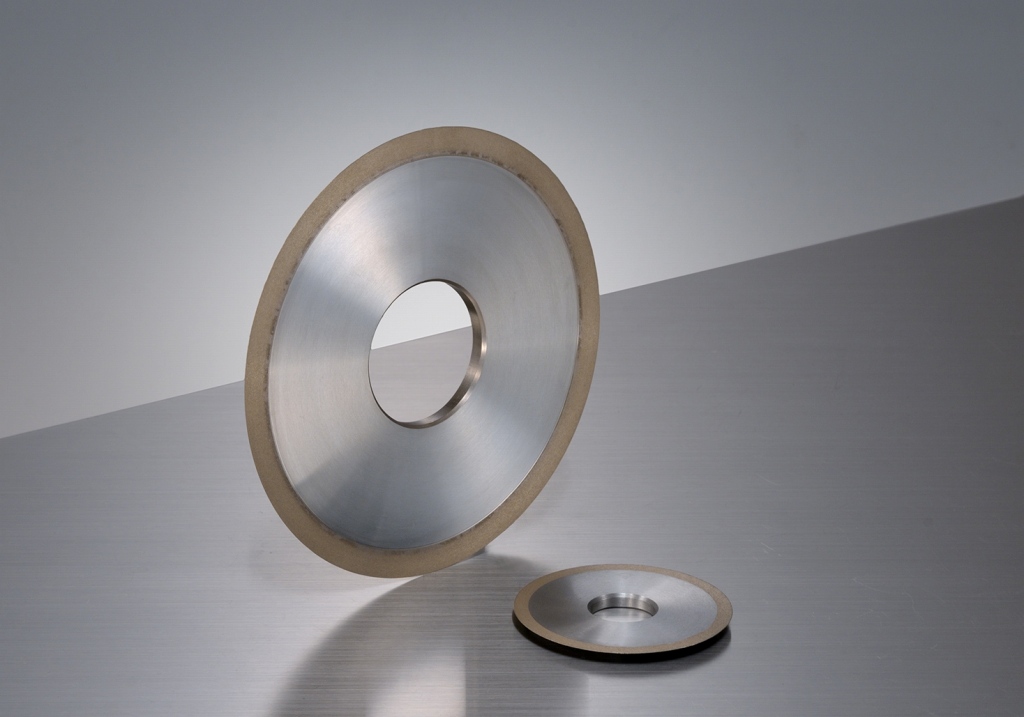

The employment of bond that has high grain holding power and excellent surface dressing performance ensures long-lasting sharpness and improvement of grinding efficiency.

| Applications | Mass production OD finishing of round bar material such as cemented carbide, ceramics and magnetic material |

|---|

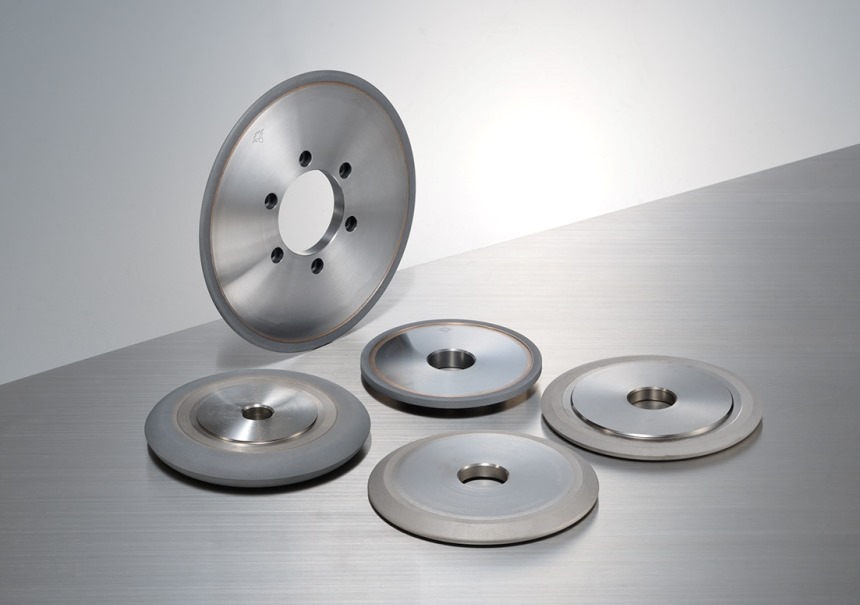

These wheels can meet various cutting requirements. They exhibit excellent performance in cutting various materials.

| Applications | Precision cutting of various ceramics, quartz, glass, ferrite, etc. |

|---|

A high performance wheel that employs metal bond of excellent heat resistance and sharpness. This wheel demonstrates the outstanding grinding performance in creep feed grinding of cemented carbide and high-speed steel tools by use of oil-based grinding fluid.

| Applications | Grooving of cemented carbide, high-speed steel end mill/drill/reamer, etc.; breaker grinding of cutting edge replacement chips; and heavy grinding of various tools and special steel tools |

|---|

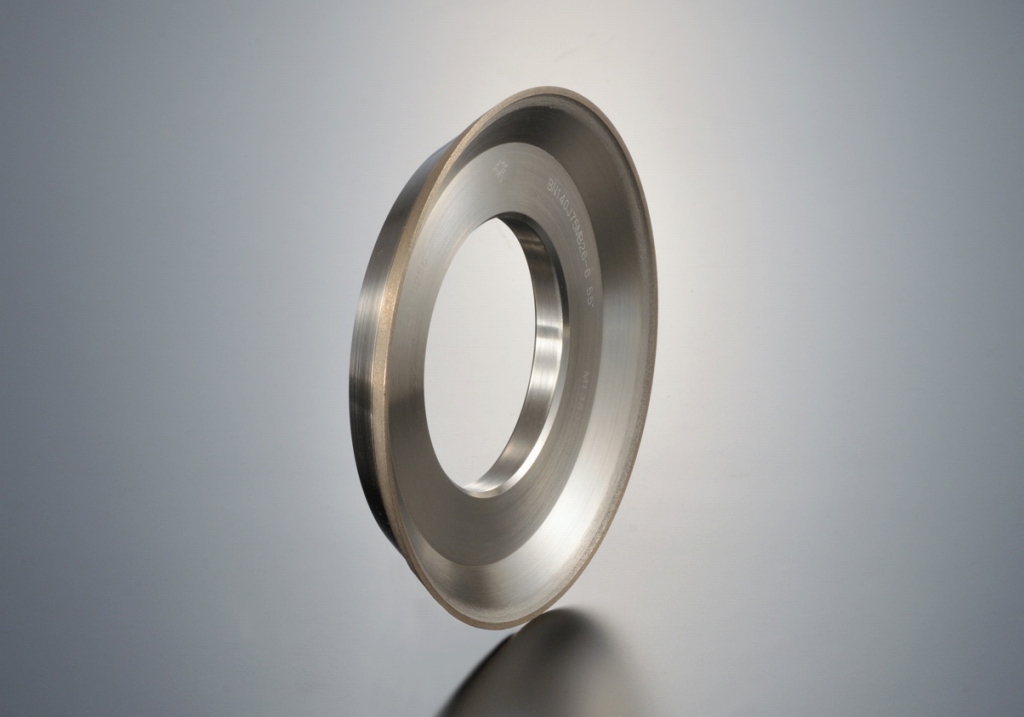

The MT Bond is new metal bond developed in pursuit of ultimate sharpness. This wheel is ideal for operations that require the sharpness of the wheel to be maintained for a long time such as surface grinding by use of a cup wheel and creep feed grinding.

| Applications | Diamond-MT bond wheels: high efficiency machining of ceramics, carbide, cermet and quartz; CBN-MT bond wheels: high efficiency machining of various ferrous materials, surface machining using cup type wheels and creep feed grinding, ideal for machining with the problem of sharpness of the wheel |

|---|

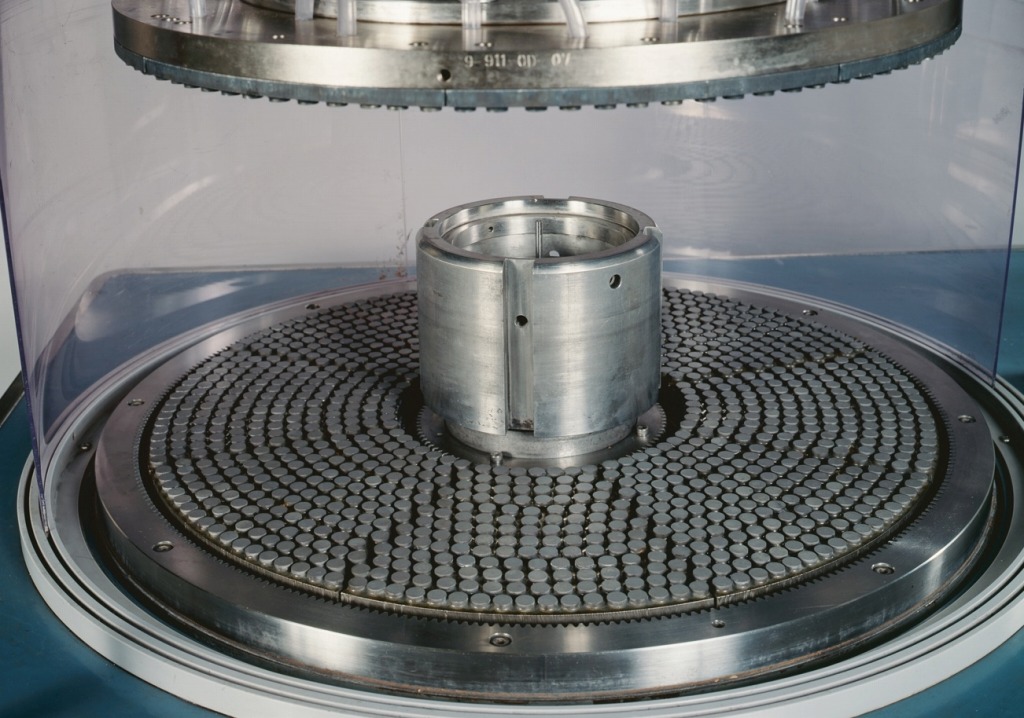

The DPG (Diamond Pellet Grinding) wheel is a bonded grain wheel developed to solve problems (such as work environment and industrial wastes generation) in lapping by use of loose abrasive grains. High efficiency and high precision lapping is possible.

| Applications | Diamond-MT bond wheels: high efficiency machining of ceramics, carbide, cermet and quartz; CBN-MT bond wheels: high efficiency machining of various ferrous materials, surface machining using cup type wheels and creep feed grinding, ideal for machining with the problem of sharpness of the wheel. |

|---|

The employment of bond that has high grain holding power, dressing performance and wear resistance ensures high efficiency grinding of various ferrous material parts and reduces tooling cost significantly.

| Applications | Industry/automobile, bearings, home appliances, tool, machine, gear, mold; Application/mass production parts processing ; Work/cam, crankshaft, injection needle, rocker arm, turbo parts, compressor parts, bearings, linear bearings, ball screw, motor parts, machine tool bed |

|---|

High grain holding power, large abrasive grain protrusion amount and abrasive grain spacing provide excellent sharpness and chips removal performance. Ideal for grinding materials such as rubber and resin that tend to cause loading.

| Applications | Rough processing of rubber, resin, etc. |

|---|

The highly wear-resistant bond that has been developed for profile grinding operations is employed. This wheel enables grinding with minimum shape deformation.

| Applications | Profile grinding of cemented carbide, cermet, etc. |

|---|

High quality is achieved to meet various beveling requirements.

| Applications | Beveling of glass, ceramic and magnetic material parts |

|---|

- Please contact below for Inquiries about diamond tools/ CBN tools