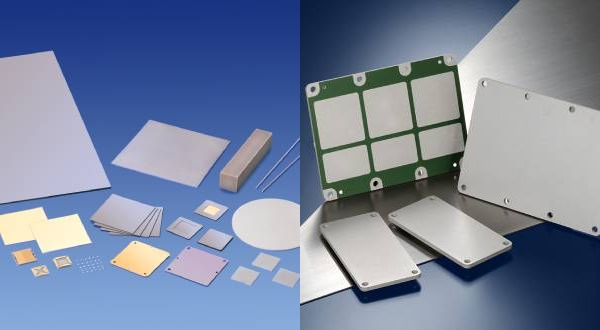

Heat spreader materials

A.L.M.T.Corp. The worlds only true “Allied” high performance heatspreaders manufacturer.

We offer a wide variety of heatspreaders of high thermal conductivity to meet various needs of customers.

Heat spreader (heat dissipation plate) by application

-

Wireless Communications

Semiconductors for wireless communications are essential for mobile phone networks. To ensure stable operation of these semiconductors, heat spreaders with high thermal conductivity are indispensable. Given the expected increase in heat generated from semiconductor devices as their speed and capacity increase with the growth of 5G, our heat spreaders are a suitable choice.

-

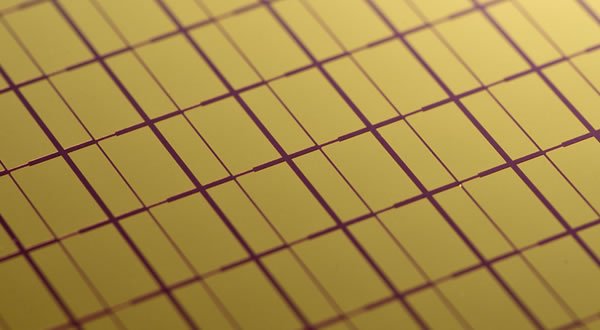

Optical Communications

Fiber-optic networks are the foundation for high-speed and high-capacity communications. For stable operation of laser devices that generate optical signals, a heat spreader with an appropriate coefficient of thermal expansion and good machinability is suitable.

-

Automotive

Hybrid vehicles and electric vehicles require a large number of electronic components that necessitate heat dissipation, such as inverters and control CPUs, which convert battery current from direct current (DC) to alternating current (AC). We offer a range of heat spreaders suitable for various cooling methods.

-

High Brightness LEDs

High brightness LED light sources are increasingly being used in automotive headlights, projectors, outdoor lighting, and other applications. Since the LEDs generate more heat than conventional lighting technologies, heat spreaders with a higher heat dissipation efficiency are required.

-

Lasers

In addition to being used for metal processes such as drilling, cutting, and welding, lasers, particularly those in medical applications like laser scalpels, increasingly requires efficient heat management. We offer heat spreaders with low thermal expansion and high thermal conductivity to handle the increased heat generation caused by the higher output of semiconductor lasers."

-

Power Generators

An offshore wind power generator, one of the new renewable energies, has a long transmission distance. Therefore, the power transmitted by these generators is usually in the form of direct current (DC). We provide heat spreaders to dissipate the heat generated by the converter that switches from AC to DC. In addition, we offer solutions for thyristors used for current control.

-

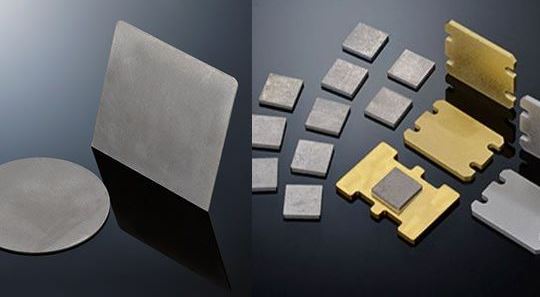

Electric Railways

High-speed rails, such as bullet trains, are equipped with numerous IGBT modules that control the power of high-output motors. To dissipate the heat generated by such power devices, we offers molybdenum-based heat spreaders that combine excellent heat dissipation characteristics and shape stability, making them suitable for IGBT modules used in rails.

-

Industrial Machinery

Industrial robots that contribute to automation and labor-saving at production sites are equipped with high-performance semiconductor devices to control high-output motors. To ensure stable operation of the robots, controlling heat dissipation of a range of semiconductor devises is necessitate. We can provide high-performance heat spreaders made from our unique materials.

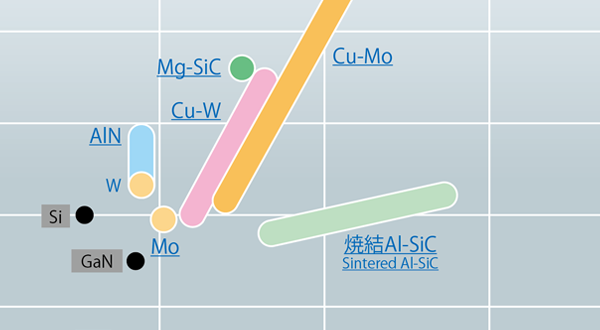

Heat spreader (heat dissipation plate) by Materials

SUMICRYSTAL is a trademark of Sumitomo Electric Industries, Ltd.