search results

15件中/1-15件目を表示

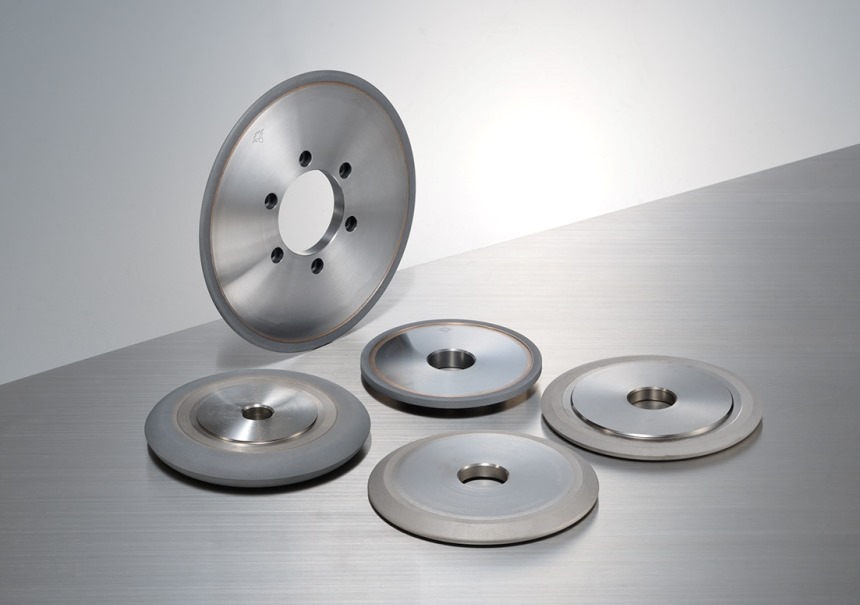

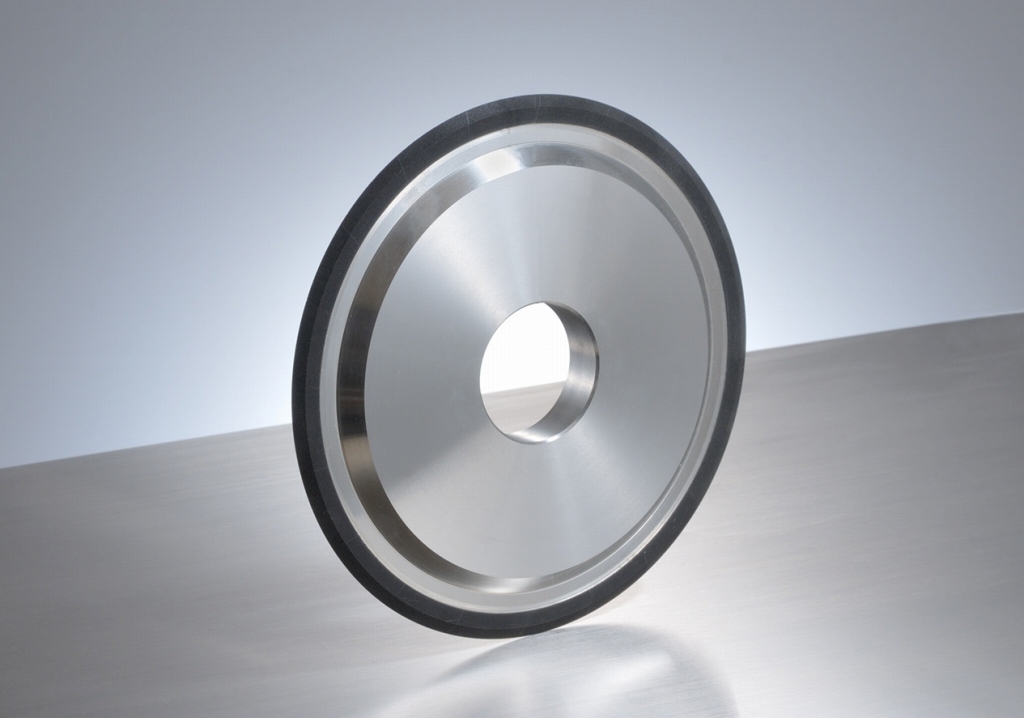

A high performance wheel that employs metal bond of excellent heat resistance and sharpness. This wheel demonstrates the outstanding grinding performance in creep feed grinding of cemented carbide and high-speed steel tools by use of oil-based grinding fluid.

| Applications | Grooving of cemented carbide, high-speed steel end mill/drill/reamer, etc.; breaker grinding of cutting edge replacement chips; and heavy grinding of various tools and special steel tools |

|---|

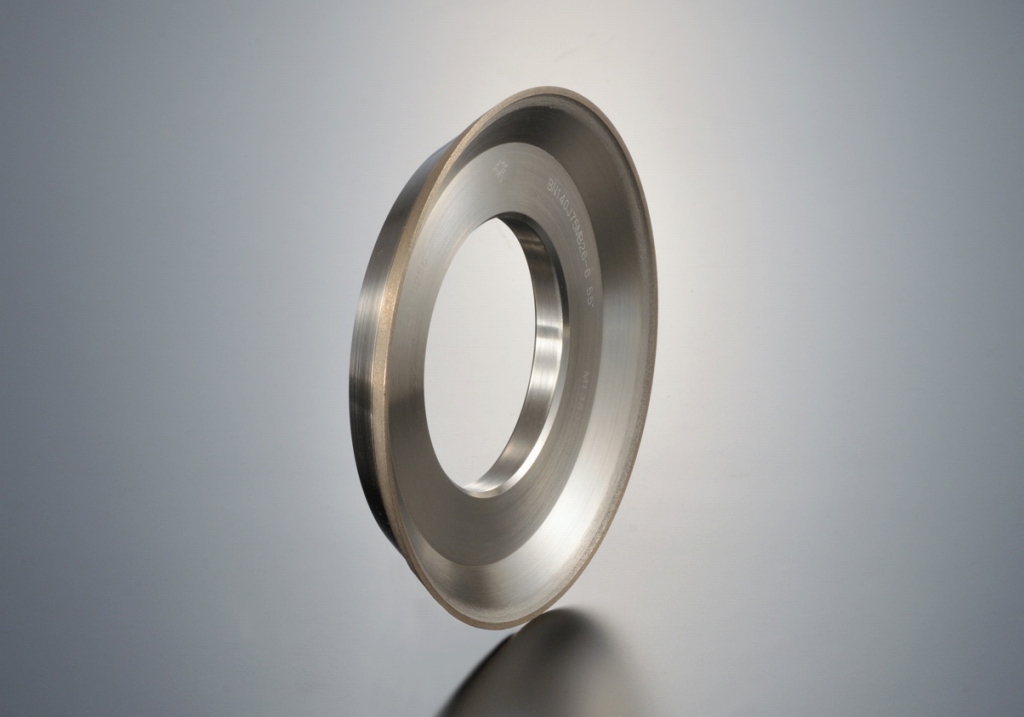

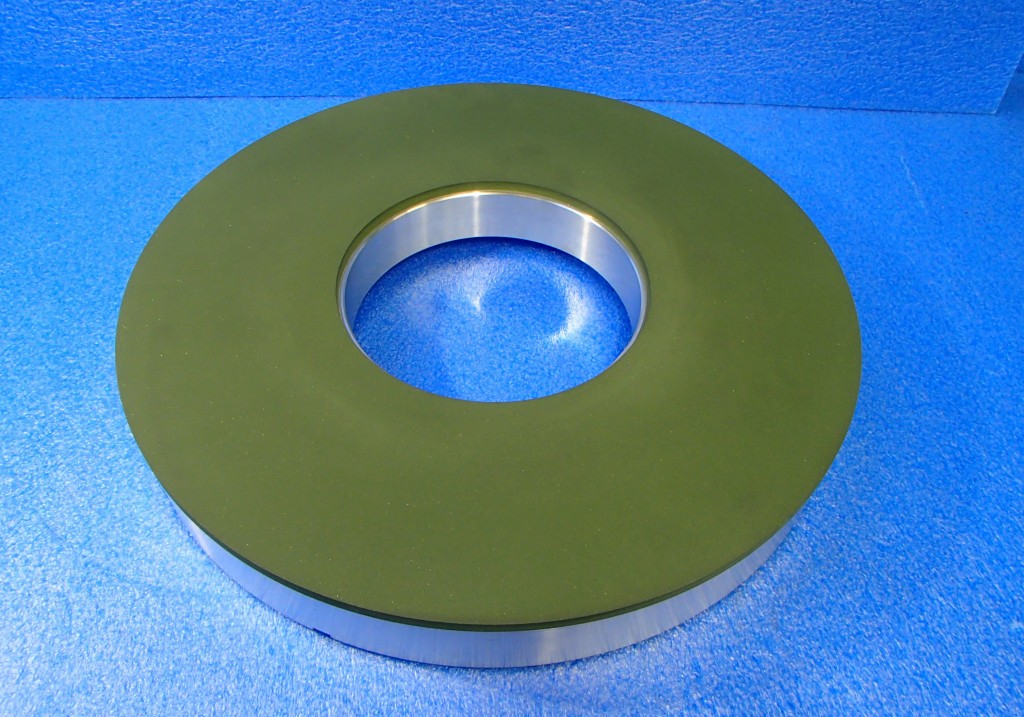

The MT Bond is new metal bond developed in pursuit of ultimate sharpness. This wheel is ideal for operations that require the sharpness of the wheel to be maintained for a long time such as surface grinding by use of a cup wheel and creep feed grinding.

| Applications | Diamond-MT bond wheels: high efficiency machining of ceramics, carbide, cermet and quartz; CBN-MT bond wheels: high efficiency machining of various ferrous materials, surface machining using cup type wheels and creep feed grinding, ideal for machining with the problem of sharpness of the wheel |

|---|

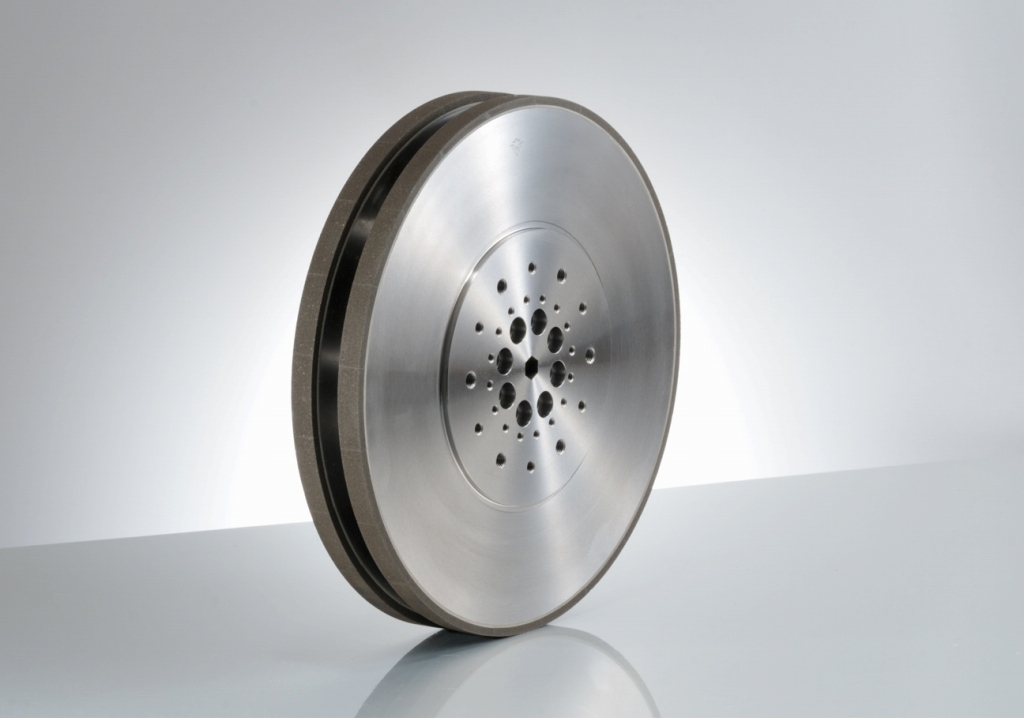

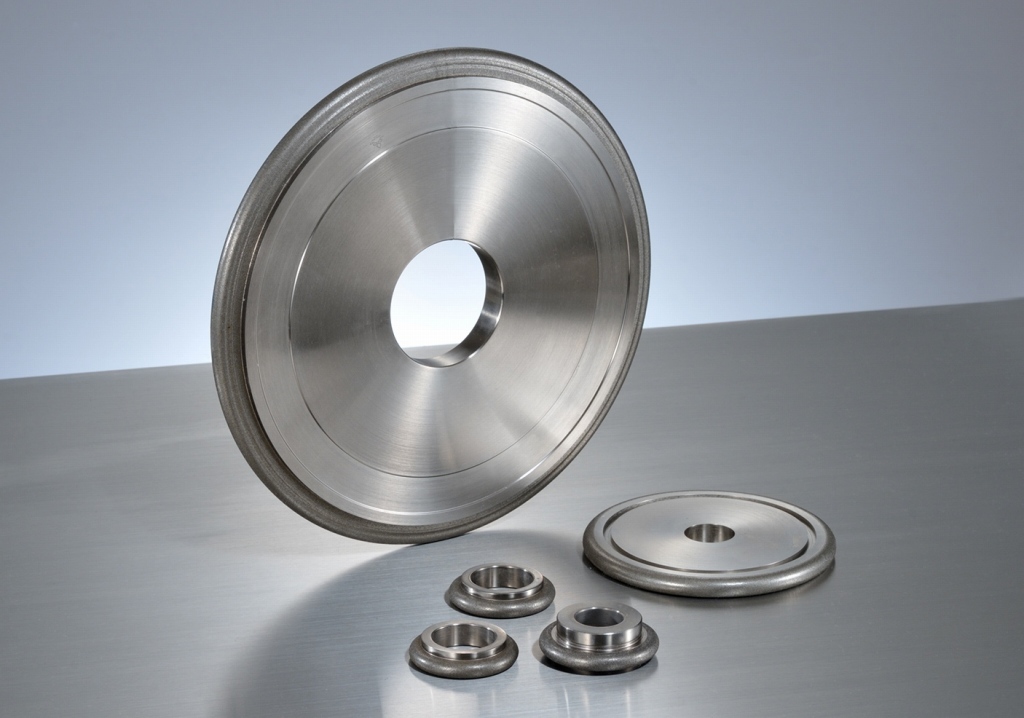

The employment of bond that has high grain holding power, dressing performance and wear resistance ensures high efficiency grinding of various ferrous material parts and reduces tooling cost significantly.

| Applications | Industry/automobile, bearings, home appliances, tool, machine, gear, mold; Application/mass production parts processing ; Work/cam, crankshaft, injection needle, rocker arm, turbo parts, compressor parts, bearings, linear bearings, ball screw, motor parts, machine tool bed |

|---|

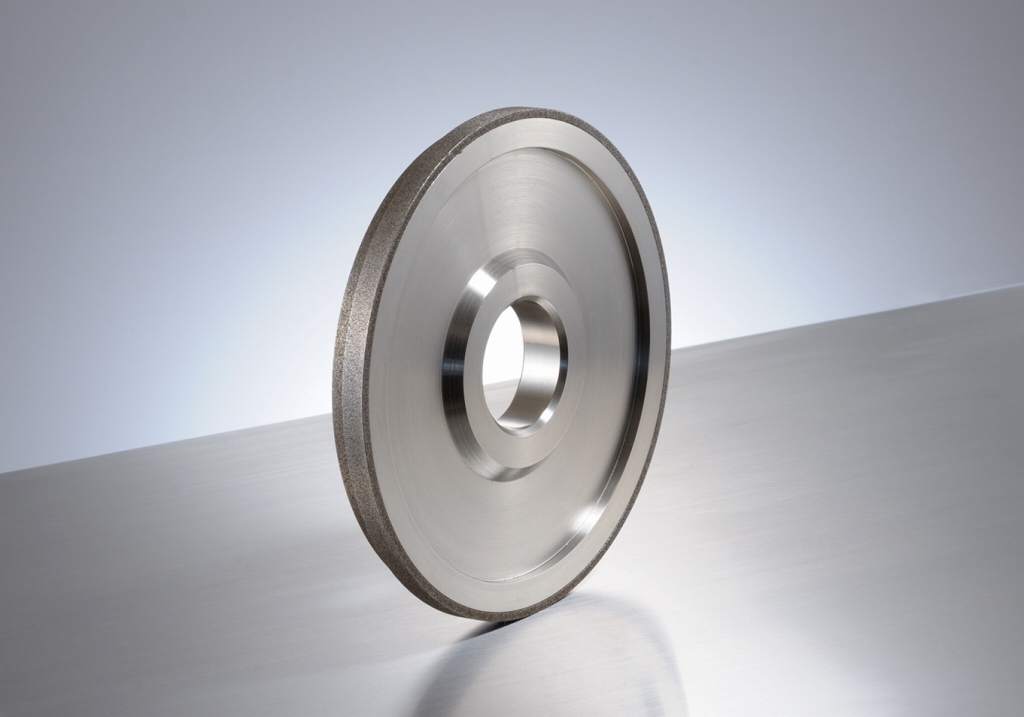

The bond that has high grain holding power and porous structure offers both sharpness and wear resistance. It ensures high efficiency and high precision grinding of cutting edges of PCD/PCBN tools.

| Applications | Processing of cutting edge of PCD/PCBN cutting tools |

|---|

The employment of bond that has high grain holding power and dressing performance ensures high efficiency grinding of various ferrous material parts and improvement of productivity.

| Applications | Industry/automobile, bearings, home appliances, tool, machine, gear, mold; Application/mass production parts processing ; Work/cam, crankshaft, injection needle, rocker arm, turbo parts, compressor parts, bearings, linear bearings, ball screw, motor parts, machine tool bed |

|---|

The employment of bond that has high grain holding power and good dressing performance & wear resistance ensures high efficiency grinding of ferrous material parts and significant tooling cost reduction.

| Applications | Industry/automobile, bearings, home appliances, tool, machine, gear, mold; Application/mass production parts processing ; Work/cam, crankshaft, injection needle, rocker arm, turbo parts, compressor parts, bearings, linear bearings, ball screw, motor parts, machine tool bed |

|---|

A wheel for high-speed grinding to offer a high level of safety and high efficiency as well as high quality.

| Applications | Industry/automobile, bearings, home appliances, tool, machine, gear, mold; Application/mass production parts processing ; Work/cam, crankshaft, injection needle, rocker arm, turbo parts, compressor parts, bearings, linear bearings, ball screw, motor parts, machine tool bed |

|---|

This wheel solves various problems associated with truing and dressing that conventional diamond wheels have suffered.

| Applications | High efficiency and high quality processing of carbide and ceramics parts |

|---|

The employment of the "BFX Bond" developed for circumference grinding realizes both of high efficiency grinding and long life.

| Applications | Cutting-edge processing of cutting-edge replacement chips of carbide/cermet |

|---|

This wheel can retain its good sharpness in grinding the thickness of cutting edge replacement chips made of carbide and cermet materials.

| Applications | Thickness processing of cutting-edge replacement chips of carbide/cermet |

|---|

This wheel offers excellent shape retention performance and good sharpness in form grinding of magnetic materials. Form grinding can be performed efficiently since truing/dressing on a machine is not required.

| Applications | High efficient total shape processing of magnetic material, carbide, ceramics, etc. |

|---|

This wheel offers excellent shape retention performance and good sharpness in form grinding of heat-resistant alloy materials. Form grinding can be performed efficiently since truing/dressing on a machine is not required.

| Applications | High efficiency total shape processing of heat resistant metal materials used for aircraft parts, etc. |

|---|

This wheel offers excellent shape retention performance and good sharpness in form grinding of ferrous materials. Form grinding can be performed efficiently and precisely since truing/dressing on a machine is not required.

| Applications | High accuracy and high efficiency total form processing of ferrous materials used for automobile parts and machine parts |

|---|

This wheel exhibits excellent performance in various grinding operations.

| Applications | Finishing holes of ferrous materials, cemented carbide, glass and ceramic materials |

|---|

This ultra high-speed wheel offers high safety, high efficiency and high quality.

| Applications | Industry/automobile, bearings, home appliances, tool, machine, gear, mold; Application/mass production parts processing ; Work/cam, crankshaft, injection needle, rocker arm, turbo parts, compressor parts, bearings, linear bearings, ball screw, motor parts, machine tool bed |

|---|

- Please contact below for Inquiries about diamond tools/ CBN tools