Examples of services

The Customer Solution Center will help you solve your various grinding and cutting problems by using varied equipment and rich experience.

We will offer any solutions possible, including process evaluation and analysis or proposal of most suitable conditions and tools.

We have also expanded our activities: offering processing consultation with e-mails and telephone calls , holding training seminars, or setting up consultation corners at exhibitions.

Process evaluation examples

CuttingEvaluation of chip cutting using high speed camera

-

Evaluate tools while checking the state of chips with high speed camera.

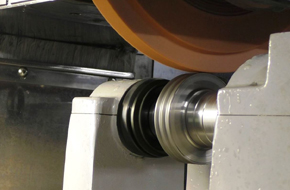

GrindingGrinding simulation using oil coolant

-

Evaluate simulation using grinding equipment of oil coolant specification.

DresserRotary Dresser evaluation using drive unit

-

Evaluate various rotary dressers using our driving units.

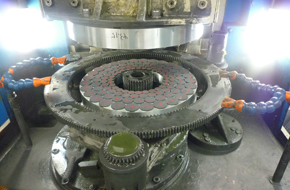

GrindingImprovement evaluation of mass-produced products using grinding machine with double-ended surface

-

Conduct evaluations to improve the efficiency and accuracy of mass-produced products using the equipment of the same type as those used at actual production sites.

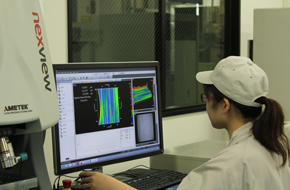

GrindingProcess evaluation of semiconductor material

-

Evaluate the process of semiconductor materials. Because workpieces can be analyzed immediately after processing, quick evaluation is possible.

Analysis examples

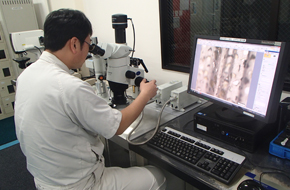

Observation of workpieces for semiconductor material

- Work analysis after processing on the spot allows faster evaluation as the following judgment can be made immediately based on the results.

Observation of grinding surface of wheel after machining

- Observation and analysis of machined wheels and workpieces allow quick judgment regarding condition or specification changes.

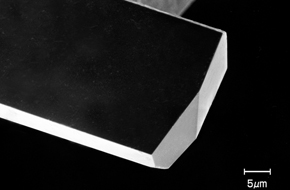

Cutting edge observation by SEM

- Observe cutting edge of cutting tools using SEM to find the usage status and problems. Quantitative observations of cutting edge change and comparison are possible because observation is possible during processing.

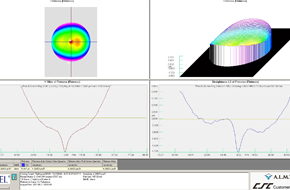

Work analysis by flatness measurement analyzer

- Obtain detailed data with the TROPEL plane analyzer to be utilized for processing various materials.

Other services

Workshop

- Hold workshops about grinding/cutting several times a year; many people have participated each time.

Exhibition

- Set up a special corner for CSC at the exhibitions such as JIMTOF and SEMICON, where you can consult directly with our CSC staff about processing and analysis.

- Please feel free to contact us

-

-

- Inquiries by email

- For emailing form

-

- Inquiries by phone

- For sales office

-