Resin bond wheels

11件中/1-11件目を表示

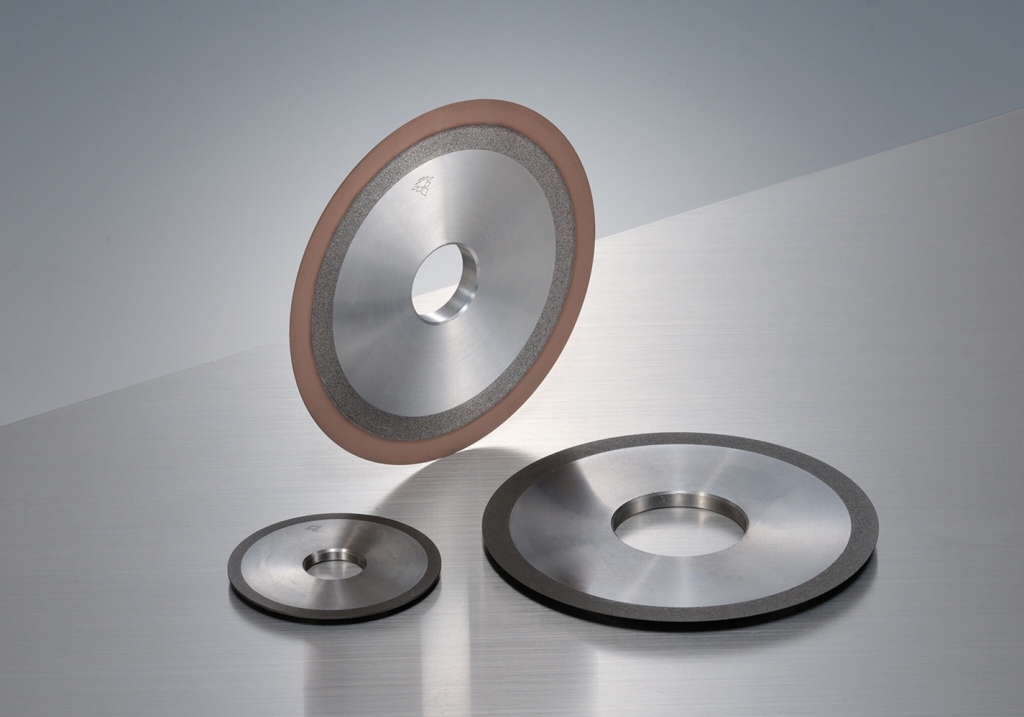

This wheel has good sharpness and shape retention in creep feed grinding of various tools such as grooving of end mills, drills and reamers.

| Applications | Grooving of end mills/drills/reamers, breaker grinding of cutting edge replacement chips, and heavy grinding of various tools and special steel tools |

|---|

This wheel demonstrates its high performance in heavy grinding of difficult-to-cut materials such as cemented carbide and cermet. In particular, in grinding operations where the heat resistance of the bond plays a critical role, this wheel offers both of good sharpness and high shape retention simultaneously.

| Applications | Grooving of end mill/drill/reamer, breaker grinding of cutting edge replacement chips, and grinding of other tools (cylindrical grinding, surface grinding, etc.) |

|---|

A hybrid structure of special metal bond having good sharpness and resin bond. The outstanding sharpness enables high efficiency and high quality grinding of difficult-to-cut cermet materials.

| Applications | Circumference grinding of hard-to-cut cermet, surface grinding, various grinding of cemented carbide and hard-to-cut ceramics |

|---|

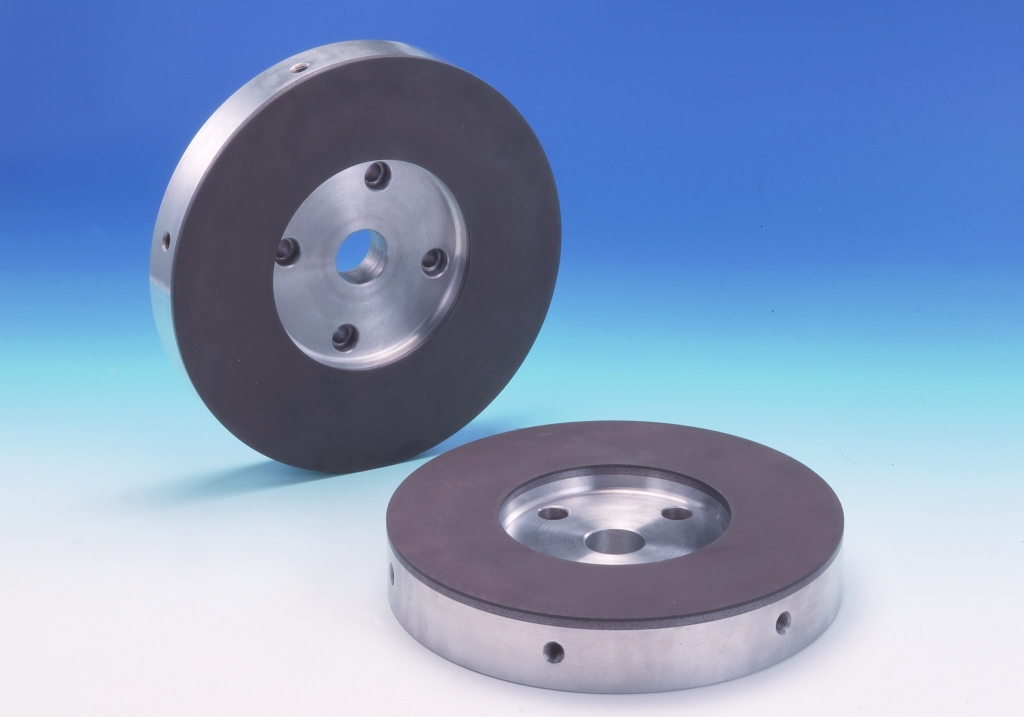

This wheel can retain its good sharpness in grinding the thickness of cutting edge replacement chips made of carbide and cermet materials.

| Applications | Thickness processing of cutting-edge replacement chips of carbide/cermet |

|---|

The employment of the "BFX Bond" developed for circumference grinding realizes both of high efficiency grinding and long life.

| Applications | Cutting-edge processing of cutting-edge replacement chips of carbide/cermet |

|---|

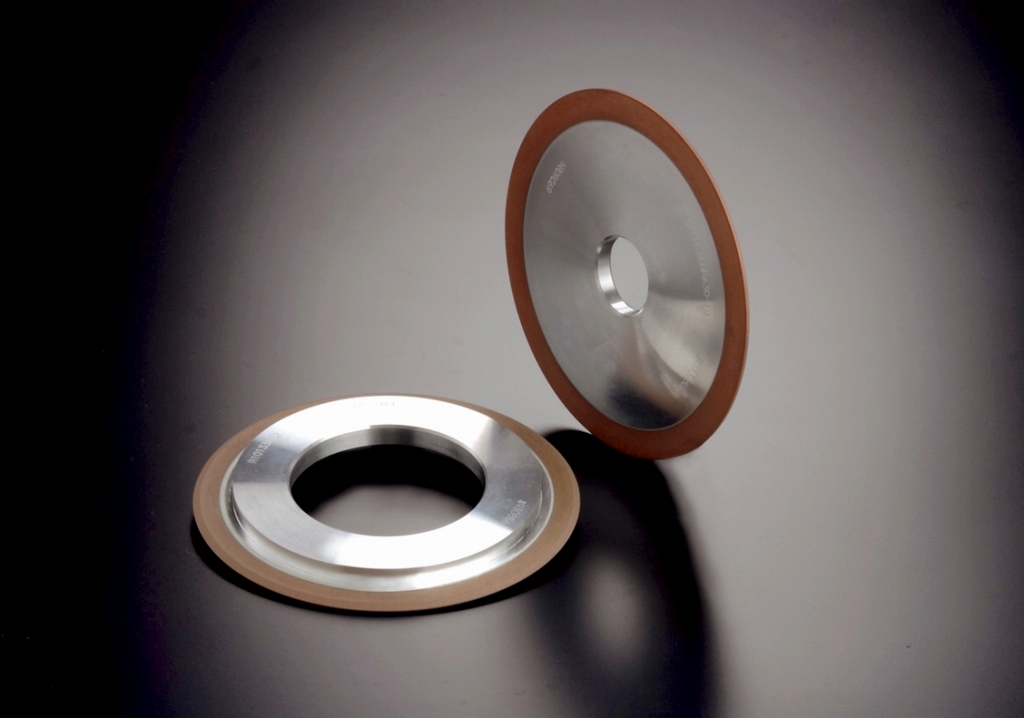

A large-size thin blade wheel for precision cutting & grooving. Since this type has high blade thickness accuracy and run-out accuracy, it is ideal for processing of precision molds of cemented carbide and ceramics.

| Applications | Grooving and cutting of carbide and ceramics precision molds, precision grooving and cutting of ferrite parts of magnetic materials |

|---|

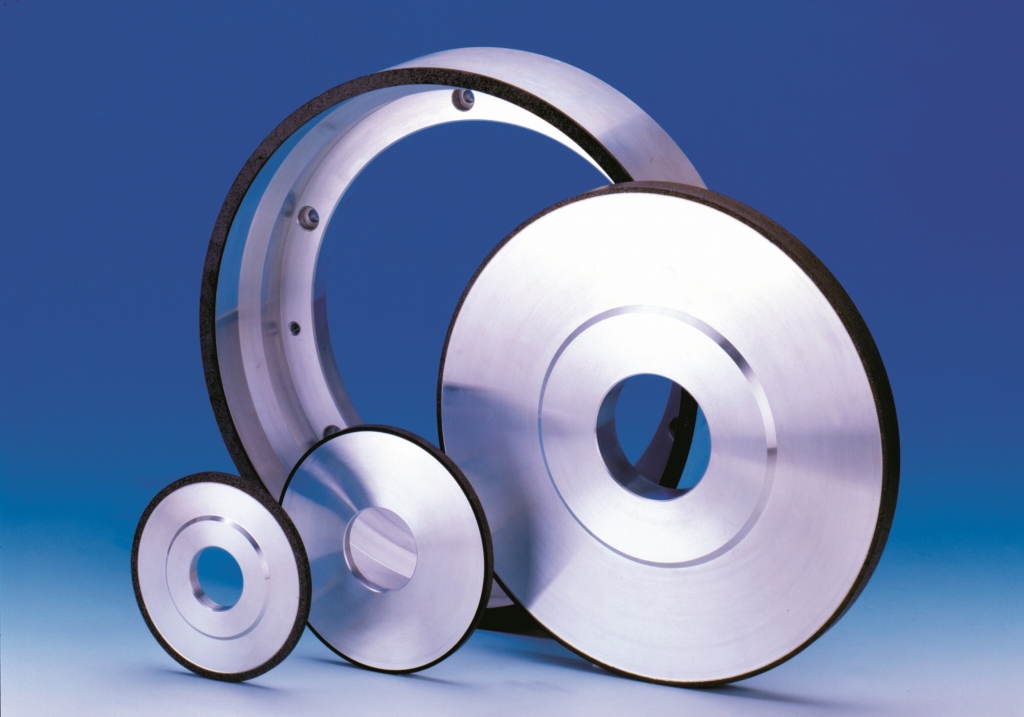

The long-lasting good sharpness and high dressing performance/wear resistance improve the grinding efficiency significantly.

| Applications | Mass-production double-ended surface grinding including pump parts for air-conditioner, oil pump parts for cars, engine parts of cars, magnetic material parts, and ceramics parts |

|---|

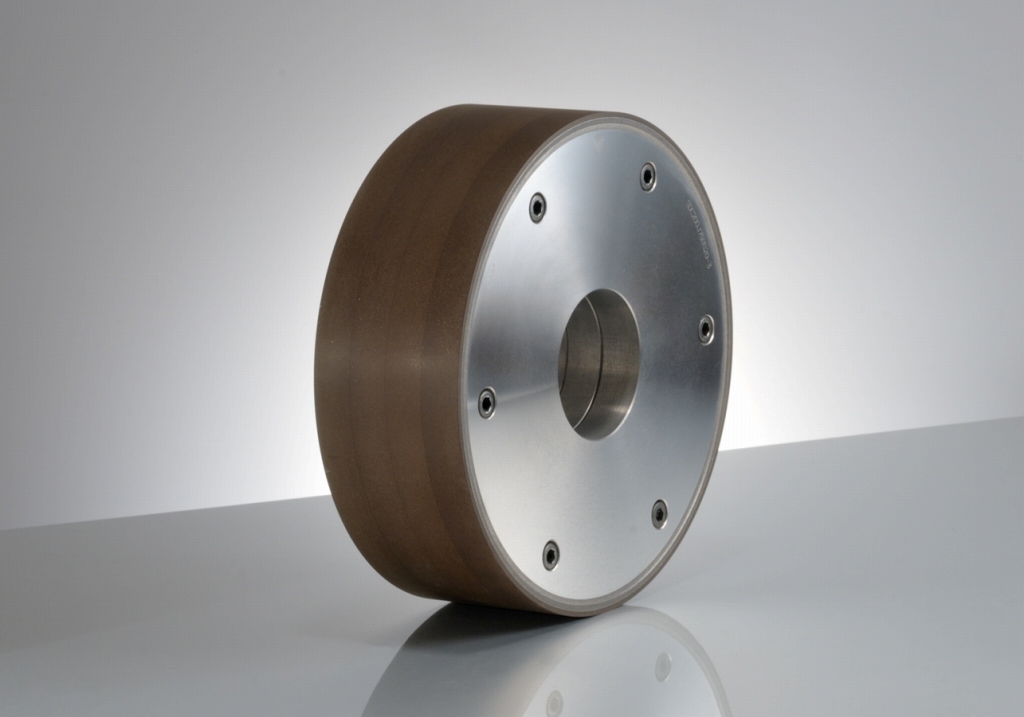

The employment of bond that has high grain holding power and excellent surface dressing performance ensures long-lasting good sharpness and grinding efficiency improvement.

| Applications | Mass production OD finishing of round bar material such as cemented carbide, ceramics and ferrous material |

|---|

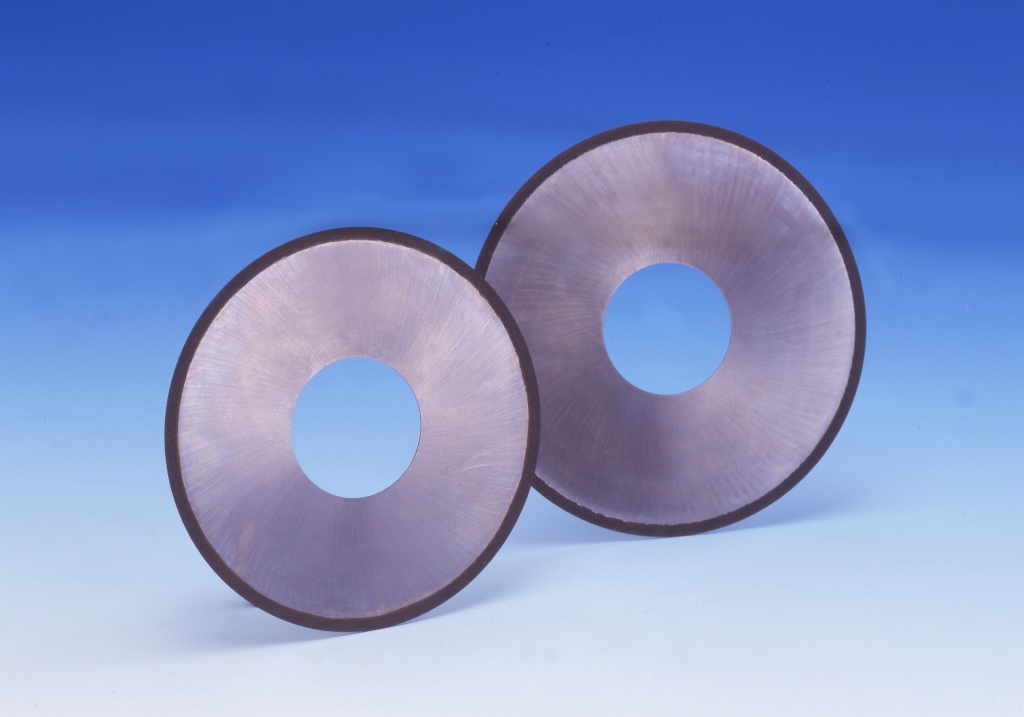

These wheels can meet various cutting requirements. They exhibit excellent performance in cutting various materials.

| Applications | Precision cutting of various ceramics, quartz, glass, ferrite, etc. |

|---|

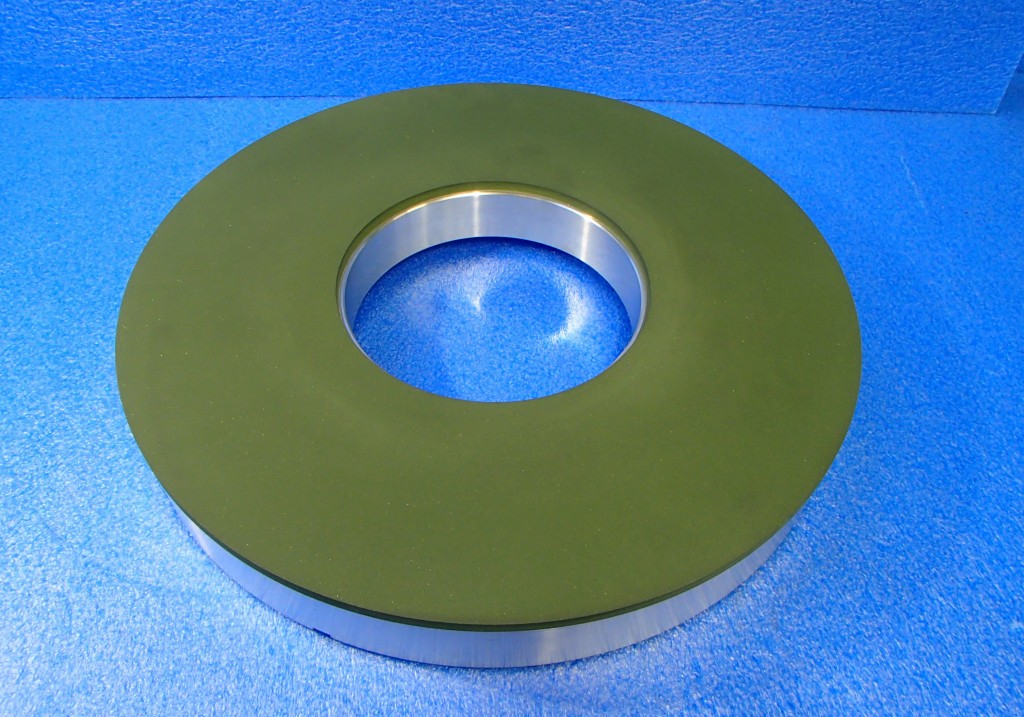

The highly wear-resistant bond that has been developed for profile grinding operations is employed. This wheel enables grinding with minimum shape deformation.

| Applications | Profile grinding of cemented carbide, cermet, etc. |

|---|

Since a highly rigid body is employed, the feed rate can be increased to provide high efficiency cutting and high cutting accuracy.

| Applications | High efficiency and high precision cutting of various ceramics, glass and magnetic materials |

|---|

- Please contact below for Inquiries about diamond tools/ CBN tools