search results

9件中/1-9件目を表示

A lineup of cutting tools for various nano/micro-forming. The cutting edge polished accurately and measured carefully by our original technologies can machine workpieces in the order of nanometer to realize high precision micro-shape machining

| Applications |

|---|

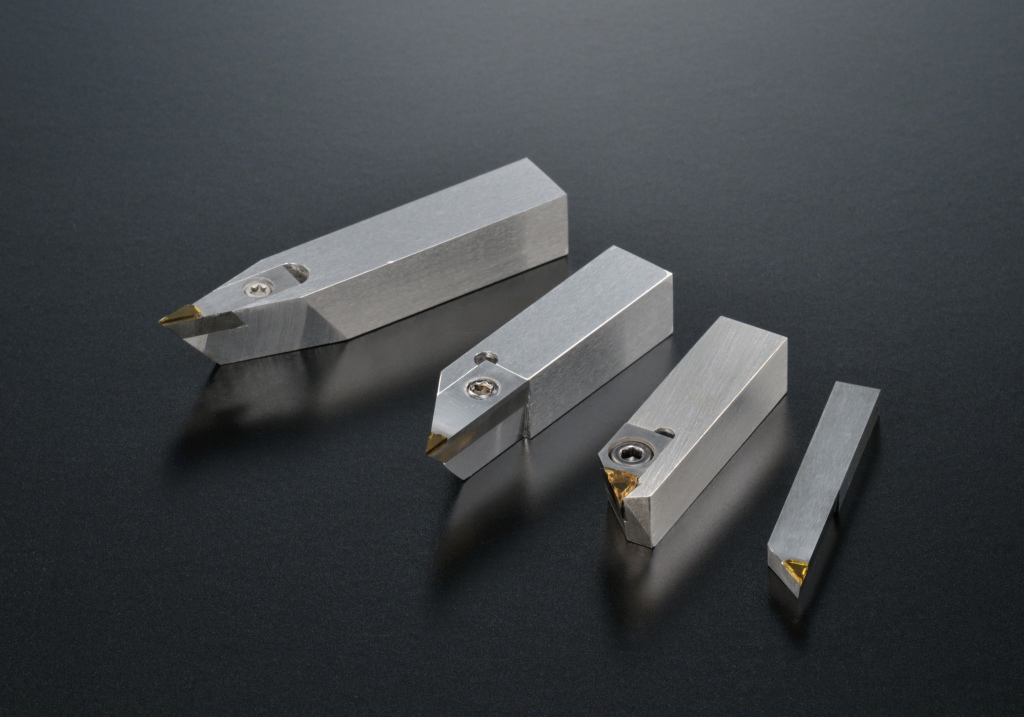

This tool has a cutting edge with high precision profile within a wide working angle range to realize excellent shape machining. This tool exhibits excellent performance in ultra-precision machining of spherical and aspherical surfaces.

| Applications | Molds of pickup lenses for CD, DVD and Blu-ray, molds of lenses for digital cameras,, molds of camera lenses for cell phones, PC and tablets, infrared lenses, spherical/aspherical mirrors for laser/X-rays, various spherical and aspherical lenses, profile machining with ultra-precision machine |

|---|

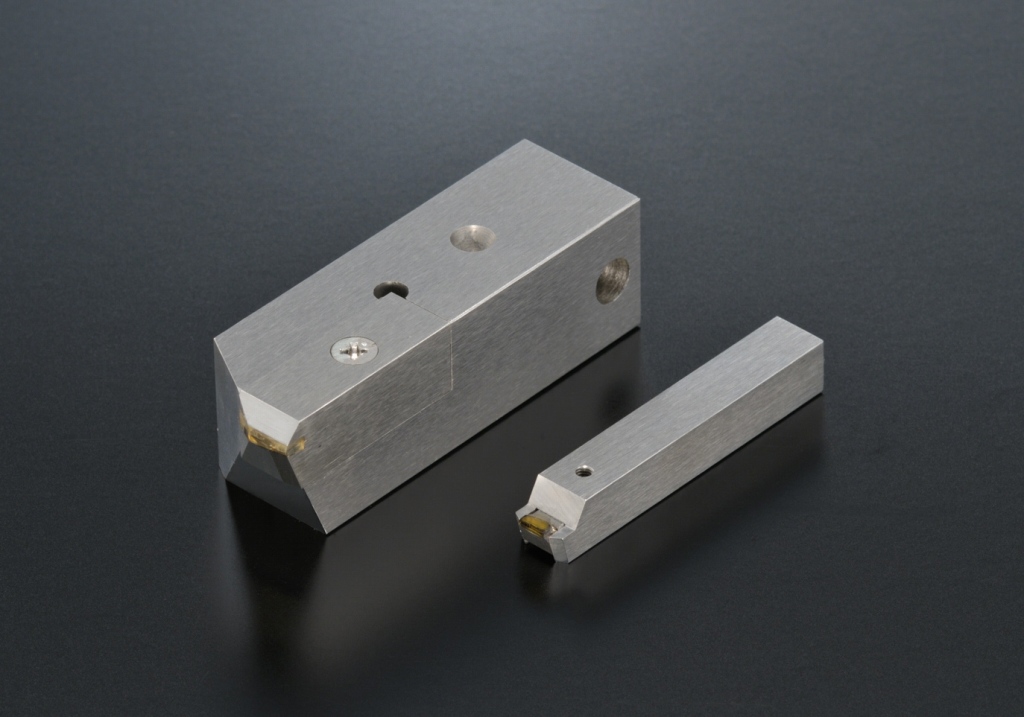

A tool ideal for high efficiency and ultra-precision cutting of planes and cylinders. An ultra-precision cutting tool that significantly reduces or eliminates the time for running-in.

| Applications | Laser reflection mirrors, polygon mirrors, copier photosensitive drums, plane and cylindrical mirror finishing |

|---|

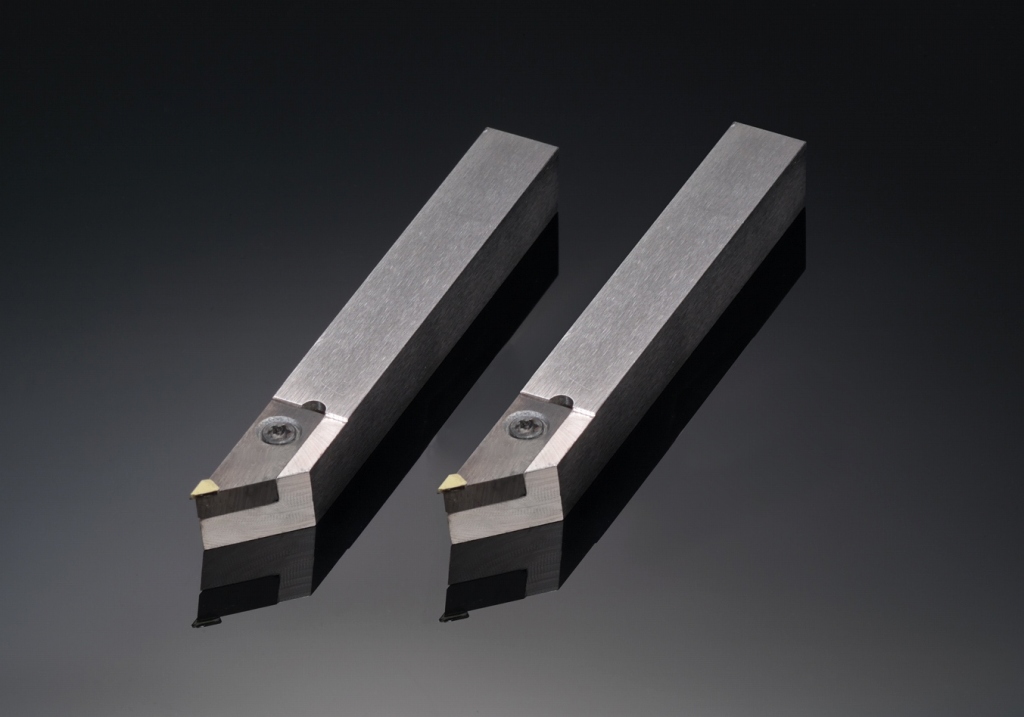

Ideal for ultra fine grooving of Fresnel lens, etc. The shape of cutting edge tips is guaranteed in the order of submicron.

| Applications | Molds of LCD light guide plates, Fresnel lens molds, optical sheet molds, various grating molds, other fine grooving |

|---|

Highly precise ultra fine grooving not achievable by the photolithography and ion beam processing can be realized.

| Applications | Holographic grating molds, linear fine grooving, molds that require ultra fine grooving, optical sheet molds |

|---|

A formed single crystal diamond cutting tool having a free curve cutting edge. Paraboloid and ellipse of profile accuracy less than 1μm can be machined in one shot

| Applications | LCD panel optical sheet molds, microlens array molds, various optical element molds |

|---|

Our original minute cutting edge treatment* has been applied to the single crystal diamond cutting edge to improve the tool life. *Patented.

| Applications | Infrared sensor lenses, night vision camera lenses, germanium lenses, silicon lenses, calcium fluoride lenses, cobalt-less carbide molds |

|---|

An ultra precision cutting tool that employs "SUMIDIA Binderless" on the UPC cutting edge. Long life in mirror-cutting of cemented carbide and machining of fine shapes is ensured. SUMIDIA is the registered trademark of Sumitomo Electric Industries, Ltd.

| Applications | Machining of cemented carbide glass lens molds, prism sheet large roll molds, light guide plate large molds, glass lenses and other high hardness and brittle materials |

|---|

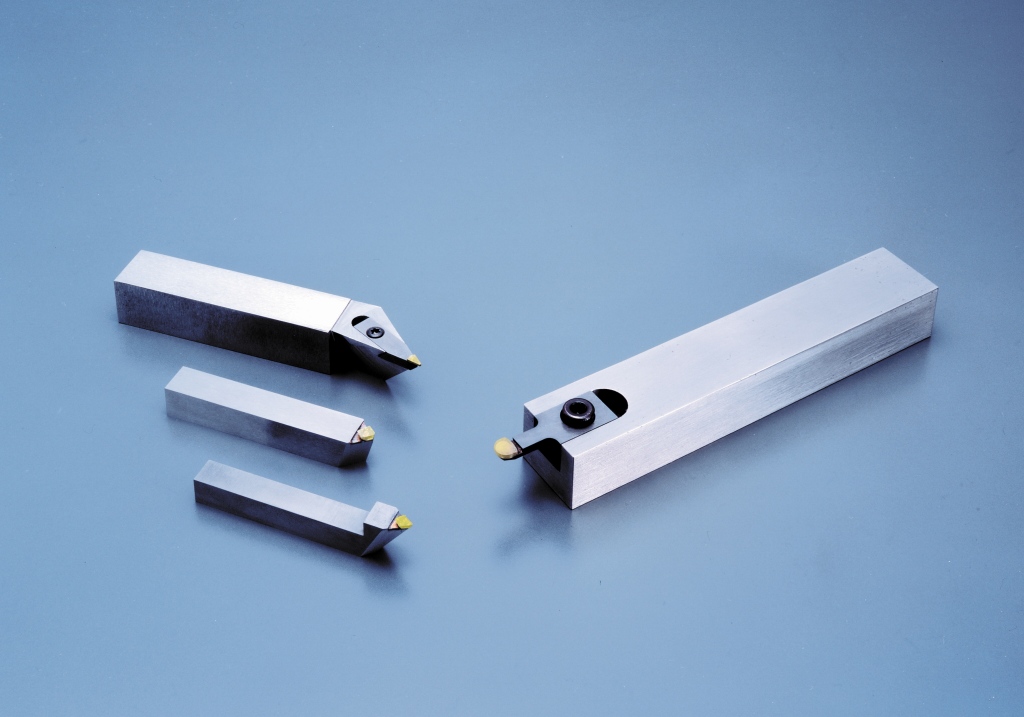

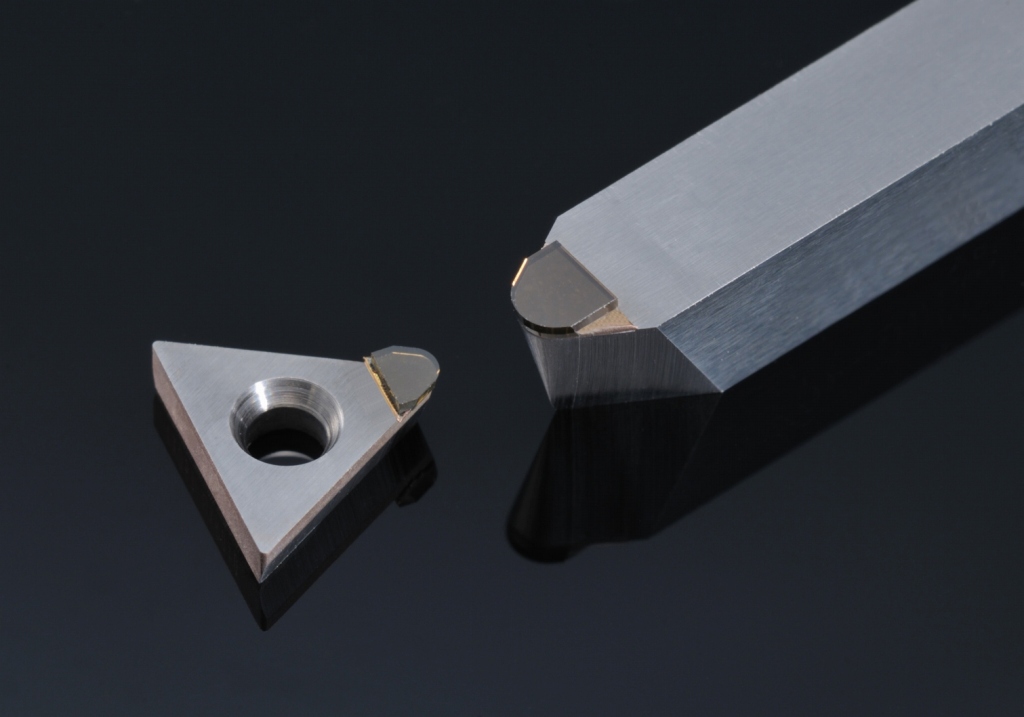

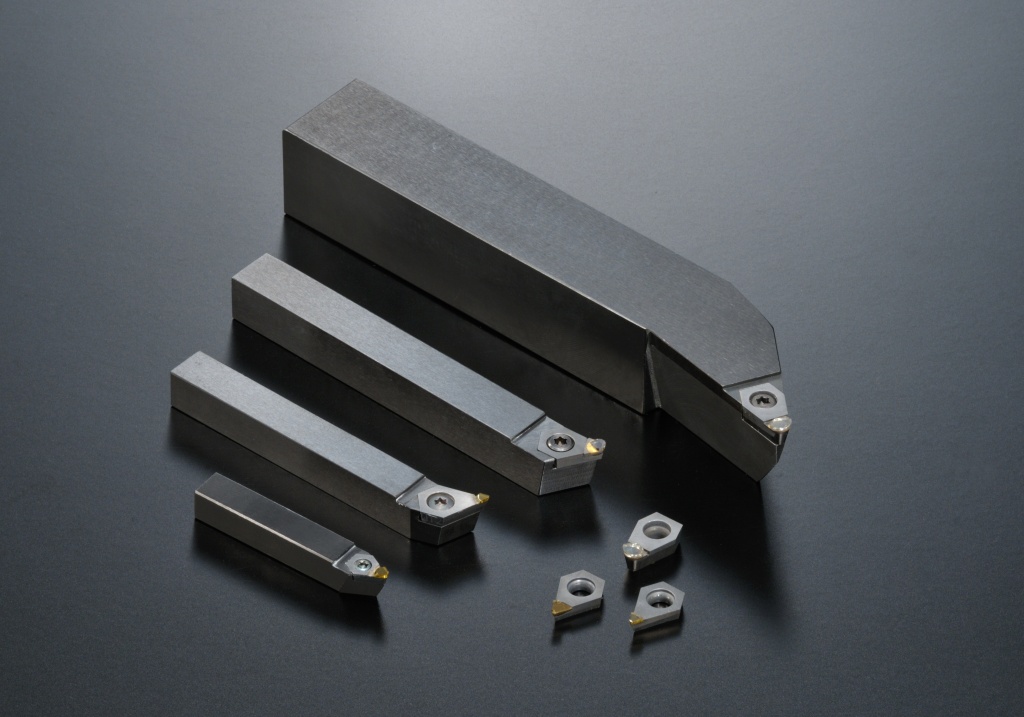

Our original precision machining technology has realized a high quality cutting edge. No chips will be fused or deposited on the rake face to keep producing high quality surfaces even during continuous operations.

| Applications | Non-ferrous metal parts such as automotive parts (pistons, aluminum wheels, compressors, commutators), plastic lenses, resin molded parts, HDD parts and aluminum die-cast parts |

|---|

- Please contact below for Inquiries about diamond tools/ CBN tools