ホーム > HOME > Product Information > Tungsten and molybdenum products > Tungsten and molybdenum products by application > Molybdenum wires

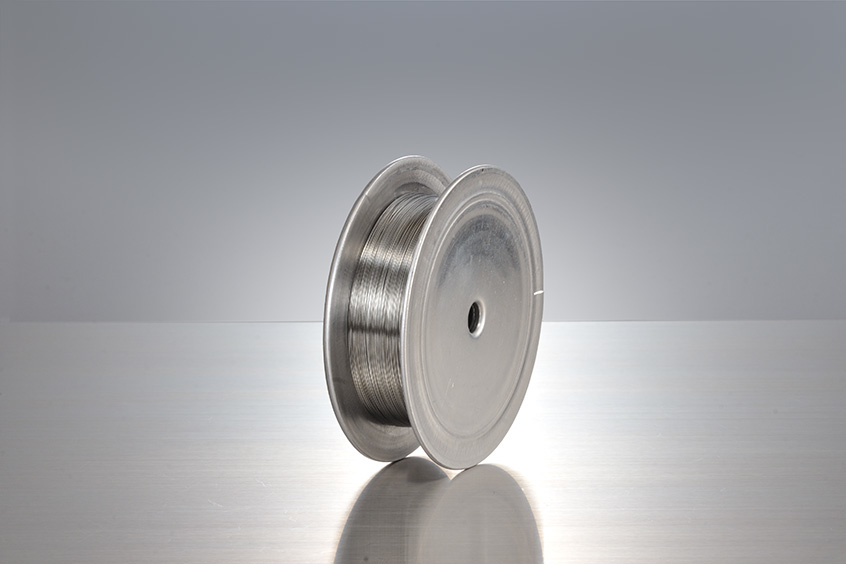

Molybdenum wires

Molybdenum wires for processing

This high-melting-point metal is easier to process than tungsten and is primarily used in high-temperature furnace components, lighting, and electron tubes. We offer a range of wire diameters and finishes to meet your specifications. Additionally, we provide TEM, a material with improved high-temperature deformation resistance achieved by incorporating trace elements, produced through our advanced, fully integrated production system starting from raw materials.

| Applications | Filaments for halogen lamps, Electrodes for projector lamps, etc. |

|---|

Materials guide

| MOP | It is the most conventional pure molybdenum material, exhibiting a high melting point, high-temperature strength, good thermal conductivity, a low coefficient of thermal expansion, and excellent workability. |

|---|---|

| MOS | The MOS type improved coiling properties and an working range, achieved through adjustments to the composition at the raw material stage. |

| TT-TEM™ | This high-quality molybdenum material overcomes the brittleness and high-temperature deformation issues associated with conventional molybdenum. It exhibits excellent high-temperature deformation resistance, a high recrystallization temperature, and a wedge-shaped recrystallized structure. Even after high-temperature use, it retains excellent impact resistance and remains deformable at room temperature, offering greater bendability than pure molybdenum. |

| TZM | Molybdenum with added Ti, Zr, and C. It has a high recrystallization temperature, high-temperature strength, and excellent creep resistance. It is used for forging tools and rotating anodes of X-ray tubes. |

スクロールで表全体をご覧いただけます。

| Type | Applications | Non-sag | Shock resistance | Machinability | Abrasion resistance |

|---|---|---|---|---|---|

| MOP | Structural heaters, Bolts, Nuts | Average | Good | Excellent | Excellent |

| MOS | Grids, Mandrels, Anchors | Good | Good | Excellent | Good |

| TT-TEM™ | Supports, Heater, Bolts, Nuts, Supporting shafts for X-ray tubes | Excellent | Excellent | Excellent | Good |

| TZM | Forging tools, Furnace components | Good | Excellent | Excellent | Excellent |

Standard specifications of Molybdenum wires

スクロールで表全体をご覧いただけます。

| Diameter range (mm) More than - Less than |

Type | Finish | Tolerance diameter (mm) |

Tolerance MG (%) |

||||

|---|---|---|---|---|---|---|---|---|

| MOP | MOS | TT-TEM™ | Drawn | Annealed | Electrolytic polished |

|||

| 0.02~0.18 | ✓ | ✓ | ✓ | ✓ | ±0.005 | ±3 | ||

| 0.18~0.20 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ±3 |

| 0.20~0.40 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ±2 |

| 0.40~0.50 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.01 | ±2 |

| 0.50~0.60 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.02 | |

| 0.60~0.80 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | |

| 0.80~1.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | |

| 1.0~1.5 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.04 | |

| 1.5~2.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ||

| 2.0~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ||

| 3.0~4.0 | ✓ | ✓ | ✓ | ✓ | ±0.05 | |||

Purity of molybdenum wires and rods

| Type | Purity(%) |

|---|---|

| MOP, MOS | 99.95 min. |

| TT-TEM™, TZM | 99.00 min. |

- Molybdenum technical information