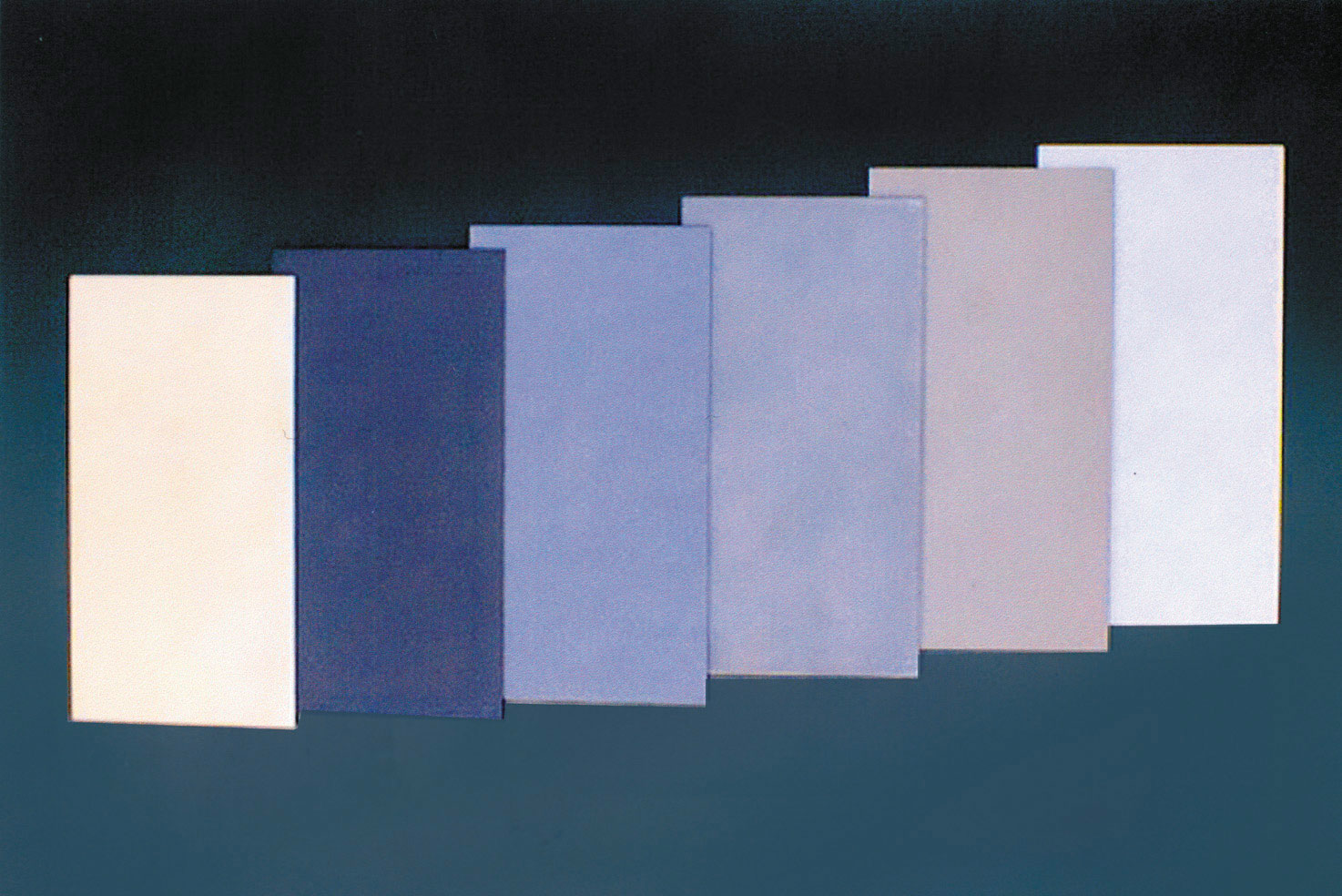

Ceramic coated molybdenum sheets / plates

Molybdenum sheets with an anti-welding effect during firing

Are you experiencing problems with welding and reactions during the firing process? Our proprietary ceramic-coated molybdenum sheets offer various advantages. Customers currently using uncoated molybdenum sheets can reduce adhesion to the furnace by switching to this product. Additionally, those using ceramic plates can expect to achieve shorter furnace cycle times, increased component charge volume, and improved accuracy of sintered products by making the switch. The coating can be customized to match the fired product and can also be applied to coat boats and other processed items.

| Applications | Jig for high temperature furnace |

|---|

スクロールで表全体をご覧いただけます。

| Applications | Coating type | Color | Examples of composition |

Examples of operating temperature (in hydrogen atmosphere or in vacuum) |

Coating thickness |

|---|---|---|---|---|---|

| Sintering MIM product (SUS-Mo, W alloy system) |

Alumina | White | Al2O399.0% | 1,400℃ | 30 to 150μm |

| Alumina-Titania | Gray | Al2O3-2.5%TiO2 | 1,400℃ | ||

| Alumina-Zirconia | Gray | Al2O3-25%ZrO2 | 1,700℃ | ||

| Zirconia -Yttria | Cream | ZrO2-8%Y2O3 | 1,400℃ | ||

| Zirconia - Silica | White with black spots | ZrO2-33%SiO2 | 1,400℃ |

* Please contact us for coating selection.

スクロールで表全体をご覧いただけます。

| Plates | Prevention of welding & reaction |

Thickness (thin) |

Heat conduction (high) |

Warp (deformation resistance) |

Characteristics |

|---|---|---|---|---|---|

| Ceramic plate | ✓ | – | – | – | Takes time to raise/lower the temperature; thick plate thickness results in a small charge amount; short lifespan of the board; deformation of the burned material. |

| Molybdenum plate (w/o coating) | – | ✓ | ✓ | ✓ | Using a ceramic board is required to prevent welding. |

| Ceramic coated molybdenum plate | ✓ | ✓ | ✓ | ✓ | While preventing welding, an increase in charge and a shortening of temperature rise/fall time may occur. |

If you currently use ceramic plates, you will achieve shorter furnace cycle times, increased charge quantities, and enhanced quality of burned material. If you currently use uncoated molybdenum plates, welding will be prevented.

- Tungsten technical information

- Molybdenum technical information