Processing products

Please contact us for high precision custom products and small quantity production.

We specialize in manufacturing tungsten and molybdenum, precisely processed into custom shapes using our advanced processing facilities. For inquiries, please contact the link below with details regarding your application, required dimensions, processing methods, finishing techniques, and more. Furthermore, we accommodate requests for small-lot production, including prototypes and test pieces.

| Applications |

Processing products for semiconductor manufacturing equipment, Sintering for high-temperature furnaces, etc. |

|---|

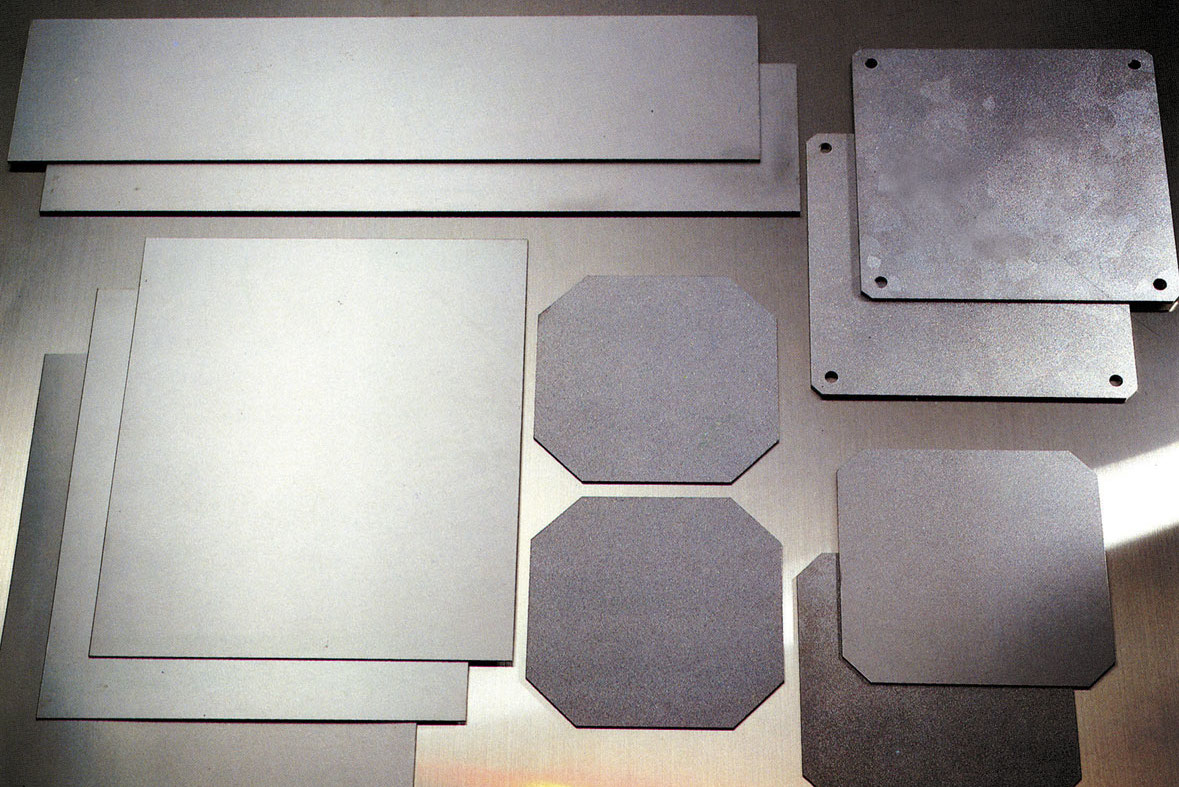

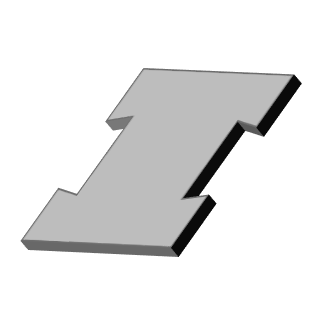

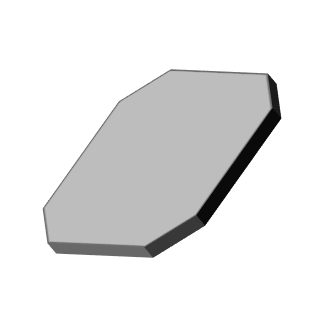

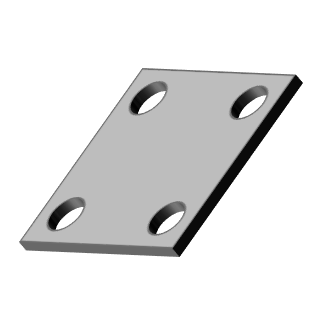

Example of processed shapes

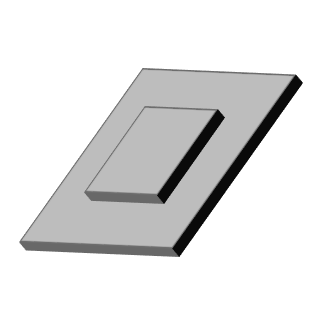

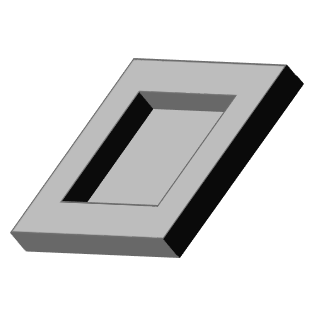

| Outer cutout shape | Polygonal shape | Drilled shape | Square plate base shape | Square plate counterbored shape |

|---|---|---|---|---|

|

|

|

|

|

| Disk shape | Ring shape | Cone-trapezoidal shape | Disk base shape | Counterbores shape |

|---|---|---|---|---|

|

|

|

|

|

Tungsten materials guide

スクロールで表全体をご覧いただけます。

| Materials | Applications | Type | Machinability | Bend formability | Impact resistance | Sputtering | Density |

|---|---|---|---|---|---|---|---|

| 3N-W | Base plate for sintering, Boats, Heaters, Reflectors, Heat spreader materials, Weights, Spacers, Various jigs and tools | Rolled products |

Excellent | Excellent | Good | Excellent | Excellent |

| 4N-W | Sputtering target materials, Hot press molds | Rolled products |

Excellent | Excellent | Good | Excellent | Excellent |

| 5N-W | Sputtering target materials | Rolled products |

Excellent | Excellent | Good | Excellent | Excellent |

Types of Tungsten plates

| Type | Purity (%) |

|---|---|

| 3N-W(General) | 99.95 min. |

| 4N-W(High purity) | 99.99 min. |

| 5N-W(Ultrahigh purity) | 99.999 min. |

| Type | Density (g/cm3) | Relative density (%) |

|---|---|---|

| Rolled products |

18.6~19.3 | 96.3~100.0 |

Tungsten sheets / plates fabrication range and tolerances

スクロールで表全体をご覧いただけます。

| Thickness (mm) More than - Less than |

Finished surface | Sizes (mm) | Tolerance (mm) Width / Length |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Rolled | Mirror | CC | Cutting | Polishing | Honing | Width (Max) | Length (Max) | ||

| 0.4~0.5 | ✓ | ✓ | ✓ | ✓ | 100 | 500 | - | ||

| 0.5~1.0 | ✓ | ✓ | ✓ | ✓ | 300 | 500 | - | ||

| 1.0~1.5 | ✓ | ✓ | ✓ | ✓ | ✓ | 300 | 500 | ±2.0 | |

| 1.5~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | 300 | 500 | ±3.0 | |

| 3.0~5.0 | ✓ | ✓ | ✓ | ✓ | ✓ | 500 | 2,000 | ±3.0 | |

| 5.0~11.0 | ✓ | ✓ | ✓ | ✓ | ✓ | 500 | 1,000 | ±3.0 | |

* For over 10 mm, please contact us for further details.

Finished surface of Tungsten sheets / plates

スクロールで表全体をご覧いただけます。

| Finished surface | Surface roughness (µm) (Typical value) |

Feautures |

|---|---|---|

| Rolled | Ra3.0 | This is the most common tungsten sheets / plates. Plates with a thickness of 3 mm or less can be heated, bent, and pressed. We also offer tungsten sheets / plates that have been sufficiently deformed to facilitate cutting and polishing processes. |

| Mirror | Ra1.6 | This tungsten sheet has been repeatedly rolled to reduce the unevenness of the surface and to add luster to the sheet. |

| CC | Ra2.9 | Acid cleaning is applied to reduce variations in surface conditions caused by rolling. |

| Cutting | Ra2.0 | If greater precision is required than what is achieved with the rolling finish, the surface is machined. |

| Polishing | Ra0.6 | If you require a higher degree of precision or smoother surface roughness than can be achieved through cutting and finishing, polishing is an option. |

| Horning | Ra2.5 | Material blasted with alumina abrasive. |

Molybdenum materials guide

スクロールで表全体をご覧いただけます。

| Type | Applications | Type | High temperature deformation resistance | Shock resistance | Bending ability | Drawing ability | Cutting ability |

|---|---|---|---|---|---|---|---|

| MOP | Heat spreader materials, Boats for deposition, Electron tubes, Furnace components, Crucibles | Standard | Average | Good | Good | Good | Excellent |

| Materials for deep drawing, Boats for evaporation coating | Cross-rolled | Average | Good | Excellent | Excellent | Excellent | |

| TT-TEM™ | Reflectors | Standard | Good | Excellent | Good | Good | Good |

| TT-DMB™ | Baking Plates Anti-welding anvils Pedestal plates Boats |

Acid washing Cutting Polishing Horning Coating |

Excellent | Average | Average | Average | Good |

| TT-TEM™-B | Excellent | Good | Excellent | Good | Average | ||

| TT-TEM™ | Acid washing Cutting Polishing |

Good | Excellent | Good | Average | Good | |

| TZM | Good | Excellent | Good | Average | Good |

Manufacturable range of Molybdenum sheets / plates

スクロールで表全体をご覧いただけます。

| Type | Thickness (mm) More than - Less than |

Finished surface | Sizes (mm) | |||

|---|---|---|---|---|---|---|

| Mirror | Acid washing | Horning | Width (Max) | Length (Max) | ||

| MOP | 0.015~0.1 *2 | ✓ | 110 | 500 | ||

| 0.1~0.15 *2 | ✓ | 350 | 1,000 | |||

| 0.15~0.2 *2 | ✓ | ✓ | 350 | 1,000 | ||

| 0.2~3.0 *2 | ✓ | ✓ | 600 | 2,000 | ||

| 3.0~25.0 | ✓ | 600 (1,000) | 1,000 (3,000) | |||

| TT-TEM™*1 | 0.2~3.0 | ✓ | ✓ | 600 | 2,000 | |

| 3.0~25.0 | ✓ | 600 (1,000) | 1,000 (3,000) | |||

| TT-TEM™-B *1 | 0.5~1.5 | ✓ | ✓ | ✓ | 300 | 600 |

| 1.5~3.0 | ✓ | ✓ | ✓ | 500 | 600 | |

| 3.0~7.0 | ✓ | ✓ | 600 | 600 | ||

| TT-DMB™ | 1.5~3.0 | ✓ | ✓ | ✓ | 500 | 600 |

| 3.0~15.0 | ✓ | ✓ | 600 | 600 | ||

| TZM | 1.0~35.0 | ✓ | ✓ | ✓ | 600 | 1,000 |

*1: Products whose structure is controlled to prevent deformation at high temperature.

*2: Able to offer products with improved diaphragm workability.

*3: The number in parentheses is the maximum size of the rolled material.

Please contact us for dimensions other than those listed above.

Standard specifications of cross-rolled molybdenum sheets / plates (Unit: mm)

スクロールで表全体をご覧いただけます。

| Thickness General tolerance±10% (mm) |

Type | Finished surface | Sizes (mm) | |

|---|---|---|---|---|

| MOP | Mirror | Width (Max) | Length (Max) | |

| 0.10~1.00 | ✓ | ✓ | 300 | 1,000 |

* Cross-rolled material is available upon request. Plate thickness tolerance may vary depending on the finish.

- Tungsten technical information

- Molybdenum technical information