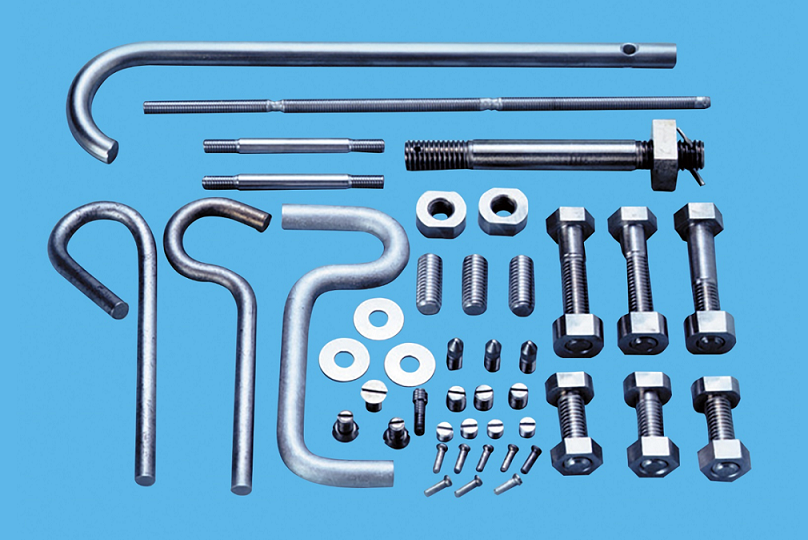

Screw parts

We can manufacture products to your specifications and applications.

Screw parts made of tungsten or molybdenum, recognized for their high specific gravity and resistance to high-temperature deformation, are extensively utilized as structural components in equipment designed for shielding or high-temperature environments. We are committed to delivering high-precision products tailored to customer specifications. Please click on the inquiry link for further details.

| Applications |

Assembly parts for environments requiring shielding or high-temperature resistance |

|---|

Tungsten rods for screw parts

スクロールで表全体をご覧いただけます。

| Type | Applications | Non-sag | Shock resistance |

Machinability | Dischargeability | Discharge consumption resistance | Abrasion resistance | Corrosion resistance (VM) |

|---|---|---|---|---|---|---|---|---|

| AW | Filaments for halogen lamps, Grids, Supports, Heaters, Electrified wires | Excellent | Good | Good | Average | Good | Good | Average |

| AX | Filaments for ultra high temperature halogen lamps (for thick and medium wires) | Excellent | Excellent | Excellent | Average | Good | Good | Average |

| EX | Vacuum deposition, High-temperature furnace heaters, Printer printing wires, Supports, Discharge electrodes, Probe pins | Good | Good | Excellent | Average | Excellent | Excellent | Excellent |

| DW | Electrodes, Charged wire thermal electron emission filaments | Good | Excellent | Excellent | Excellent | Excellent | Good | Average |

| CY (PFW) |

Structural and furnace heaters | Average | Average | Excellent | Average | Average | Good | Excellent |

| EP | Discharge electrodes, Structural materials, Welding electrodes | Good | Average | Excellent | Average | Excellent | Excellent | Average |

| KT | Discharge electrodes, Structural materials | Good | Average | Excellent | Average | Excellent | Excellent | Average |

| 4N-W 5N-W |

Electrodes, Heaters | Average | Average | Excellent | Average | Good | Excellent | Good |

| LW | Structural materials, discharge electrodes, | Good | Excellent | Excellent | Good | Good | Good | Average |

Standard specifications of tungsten rods

スクロールで表全体をご覧いただけます。

| Diameter range (mm) More than - Less than |

Type | Finish | Tolerance diameter (mm) |

Finish grinding *1 |

Tolerance diameter (mm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AW | AX | EX | CY PFW |

4N-W 5N-W |

EP KT |

LW | Drawn, Swaged |

Electrolytic Polished |

Chemical Cleaned |

||||

| ~0.15 | ✓ | ✓ | ✓ | ±0.005 | |||||||||

| 0.15~0.20 | ✓ | ✓ | ✓ | ±0.005 | |||||||||

| 0.20~0.40 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ||||||

| 0.40~0.50 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.01 | ||||||

| 0.50~0.60 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.02 | ||||||

| 0.60~0.80 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | |||||

| 0.80~1.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ✓ | ±0.03 | ||||

| 1.0~1.3 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ✓ | ±0.03 | |||||

| 1.3~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.03 | |||||

| 3.0~5.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | ||||

| 5.0~6.4 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.2 | ✓ | ±0.05 | ||||

| 6.4~8.6 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.25 | ✓ | ±0.1 | ||||

| 8.6~12.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.3 | ✓ | ±0.1 | |||||

| 12.0~15.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.4 | ✓ | ±0.1 | |||||

| 15.0~18.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.5 | ✓ | ±0.15 | ||||

| 18.0~(40.0) | ✓ | ✓ | ✓ | ✓ | ✓ | ±1.0 | ✓ | ±0.2 | |||||

*1 Finish grinding: Centerless grinding for diameters less than 30 mm, and cutting-belt grinding for diameters of 30 mm and larger.

Manufacturable range and standard tolerances for Tungsten rod lengths

スクロールで表全体をご覧いただけます。

| Diameter (mm) | Standard length (tolerance) :mm | Max length (tolerance) :mm |

|---|---|---|

| 5 | 1,000 (+10/0) | 11,000 (±50) |

| 6 | 1,000 (+10/0) | 7,500 (±50) |

| 8 | 1,100 (+10/0) | 4,000 (±50) |

| 11 | 1,000 (+10/0) | 3,000 (±50) |

| 16 | 1,200 (+10/0) | 1,500 (±50) |

| 21 | 1,100 (+10/0) | 1,500 (+10/0) |

| 25 | 850 (+5/0) | 1,500 (+10/0) |

| 31 | 700 (+5/0) | 1,400 (+10/0) |

| 36 | 500 (+5/0) | 1,000 (+10/0) |

| 41 | 400 (+4/0) | 800 (+5/0) |

| 45 | 300 (+4/0) | 600 (+5/0) |

| 50 | 230 (+3/0) | 450 (+4/0) |

please contact us for dimensions other than those mentioned above.

Purity of Tungsten rods

| Type | Purity(%) |

|---|---|

| AW, AX, EX, CY, EP, KT | 99.95 min. |

| DW | 99.00 min. |

| LW | 97.00 min. |

| 4N-W | 99.99 min. |

| 5N-W | 99.999 min. |

Molybdenum rods for screw parts

スクロールで表全体をご覧いただけます。

| Type | Applications | Non-sag | Shock resistance |

Machinability | Abrasion resistance |

|---|---|---|---|---|---|

| MOP | Structural, Heaters, Bolts, Nuts | Average | Good | Excellent | Excellent |

| MOS | Grid, Mandrels, Anchors | Good | Good | Excellent | Good |

| TT-TEM™ | Supports, Heaters, bolts, Nuts, Supporting shafts for X-ray tubes | Excellent | Excellent | Excellent | Good |

| TZM | Forging tools, Furnace components | Good | Excellent | Excellent | Excellent |

Standard specifications of molybdenum rods

スクロールで表全体をご覧いただけます。

| Diameter range (mm) More than - Less than |

Type | Finish | Tolerance diameter (mm) |

Finish grinding *1 |

Tolerance diameter (mm) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| MOP | MOS | TT-TEM™ | TZM | Drawn, Swaged |

Electrolytic polished |

Chemical cleaned |

||||

| 0.02~0.20 | ✓ | ✓ | ✓ | ±0.005 | ||||||

| 0.20~0.40 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ||||

| 0.40~0.50 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.01 | ||||

| 0.50~0.60 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.02 | ||||

| 0.60~0.80 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ||||

| 0.80~1.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ✓ | |||

| 1.0~1.5 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.02 | ||

| 1.5~2.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.02 | ||

| 2.0~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.03 | ||

| 3.0~4.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | ||

| 4.0~4.6 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | ||

| 4.6~5.0 | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | |||

| 5.0~6.4 | ✓ | ✓ | ✓ | ✓ | ±0.2 | ✓ | ±0.05 | |||

| 6.4~8.6 | ✓ | ✓ | ✓ | ✓ | ±0.25 | ✓ | ±0.05 | |||

| 8.6~12.0 | ✓ | ✓ | ✓ | ±0.3 | ✓ | ±0.05 | ||||

| 12.0~15.0 | ✓ | ✓ | ✓ | ±0.4 | ✓ | ±0.1 | ||||

| 15.0~22.0 | ✓ | ✓ | ✓ | ±0.5 | ✓ | ±0.15 | ||||

| 22.0~26.0 | ✓ | ✓ | ✓ | ✓ | ±0.6 | ✓ | ±0.15 | |||

| 26.0~28.0 | ✓ | ✓ | ✓ | ✓ | ±0.7 | ✓ | ±0.2 | |||

| 28.0~50.0 | ✓ | ✓ | ✓ | ✓ | ±1.0 | ✓ | ±0.2 | |||

*1 Finish grinding: Centerless grinding for diameters less than 30 mm. and cutting-belt grinding for diameters of 30 mm and larger.

*2 For products with a diameter of 50 mm or greater, please contact us.

Purity of molybdenum wires and rods

| Type | Purity(%) |

|---|---|

| MOP、MOS | 99.95 min. |

| TT-TEM™, TZM | 99.00 min. |

- Tungsten technical information

- Molybdenum technical information