Vitrified bond wheels

14件中/1-14件目を表示

The employment of bond that has high grain holding power and excellent surface dressing performance ensures long-lasting good sharpness and grinding efficiency improvement.

| Applications | Mass production OD finishing of ferrous round bar material |

|---|

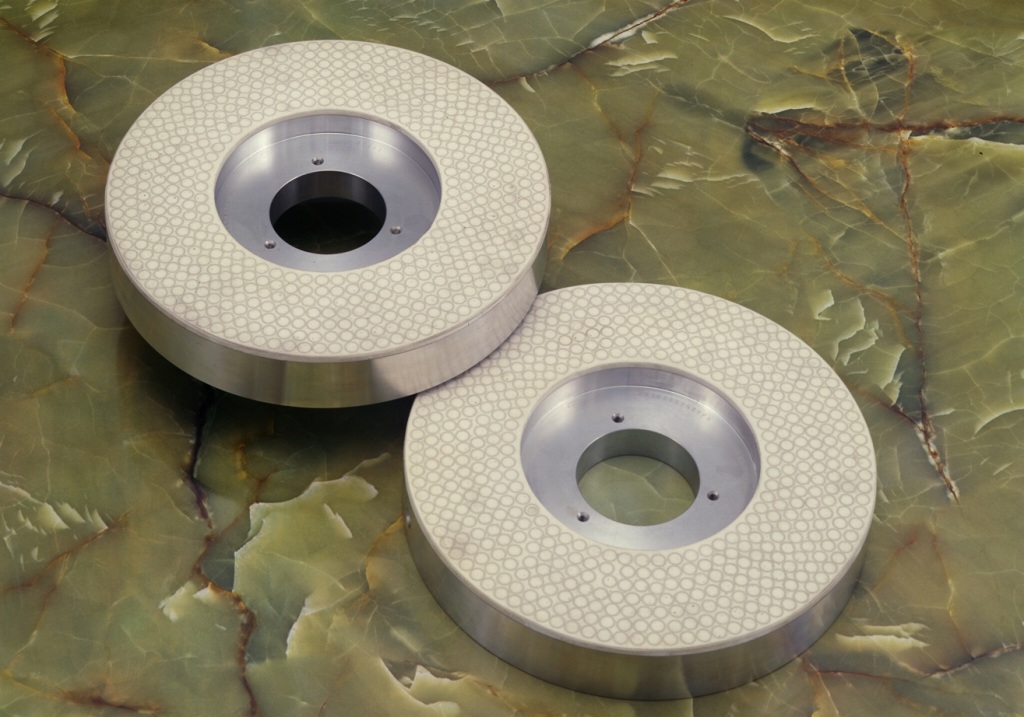

The DPG (Diamond Pellet Grinding) wheel is a bonded grain wheel developed to solve problems (such as work environment and industrial wastes generation) in lapping by use of loose abrasive grains. High efficiency and high precision lapping is possible.

| Applications | High precision and high efficiency thickness processing of ferrous material, carbide, glass, ceramics, etc. |

|---|

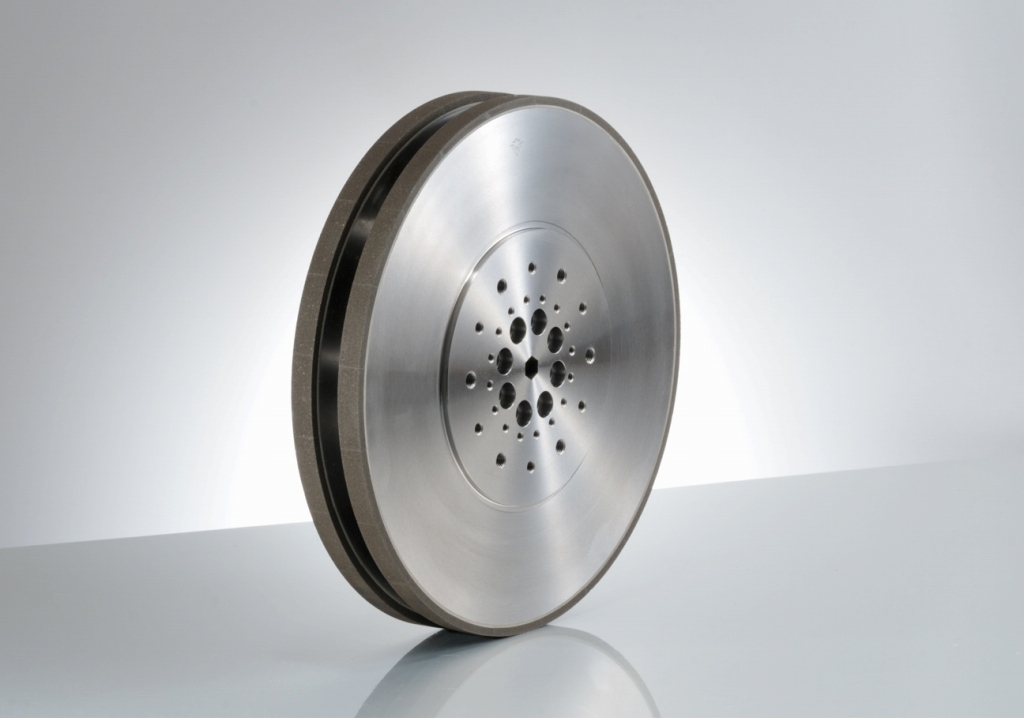

The bond that has high grain holding power and porous structure offers both sharpness and wear resistance. It ensures high efficiency and high precision grinding of cutting edges of PCD/PCBN tools.

| Applications | Processing of cutting edge of PCD/PCBN cutting tools |

|---|

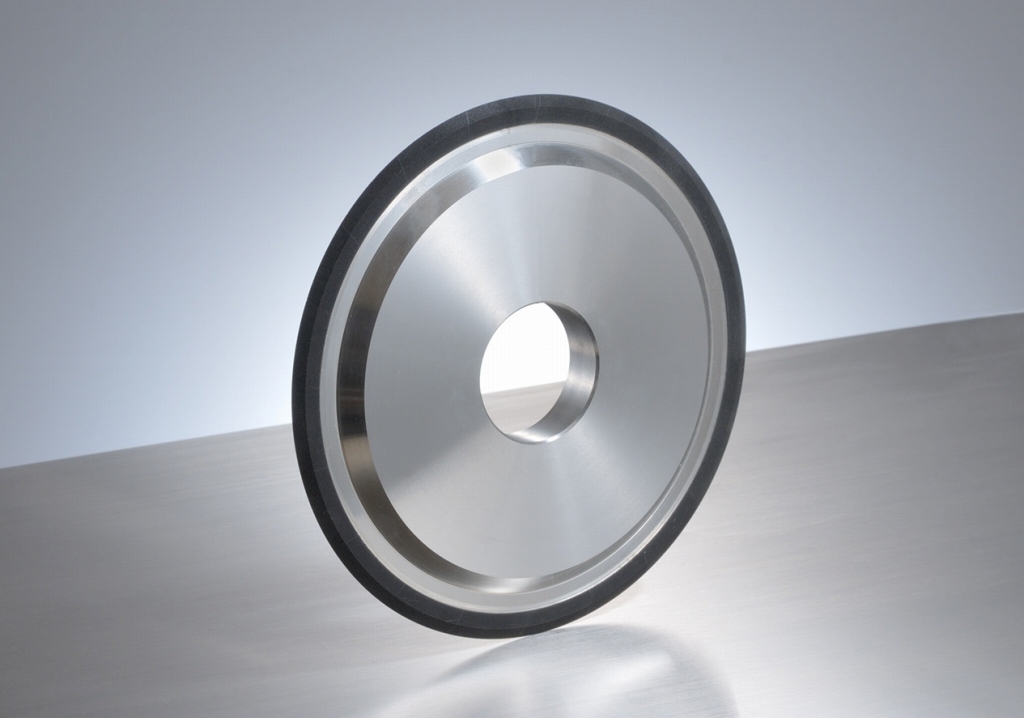

The employment of bond that has high grain holding power and dressing performance ensures high efficiency grinding of various ferrous material parts and improvement of productivity.

| Applications | Industry/automobile, bearings, home appliances, tool, machine, gear, mold; Application/mass production parts processing ; Work/cam, crankshaft, injection needle, rocker arm, turbo parts, compressor parts, bearings, linear bearings, ball screw, motor parts, machine tool bed |

|---|

The employment of bond that has high grain holding power and good dressing performance & wear resistance ensures high efficiency grinding of ferrous material parts and significant tooling cost reduction.

| Applications | Industry/automobile, bearings, home appliances, tool, machine, gear, mold; Application/mass production parts processing ; Work/cam, crankshaft, injection needle, rocker arm, turbo parts, compressor parts, bearings, linear bearings, ball screw, motor parts, machine tool bed |

|---|

A wheel for high-speed grinding to offer a high level of safety and high efficiency as well as high quality.

| Applications | Industry/automobile, bearings, home appliances, tool, machine, gear, mold; Application/mass production parts processing ; Work/cam, crankshaft, injection needle, rocker arm, turbo parts, compressor parts, bearings, linear bearings, ball screw, motor parts, machine tool bed |

|---|

This wheel solves various problems associated with truing and dressing that conventional diamond wheels have suffered.

| Applications | High efficiency and high quality processing of carbide and ceramics parts |

|---|

A vitrified bond wheel having high grain holding power. The high porosity structure and the characteristic grain layer shape realize low grinding resistance and create a new grinding region.

| Applications | Primary grinding of as deposition and as-sliced wafers, etc. |

|---|

Continuous grinding of single crystal SiC wafers that are difficult to grind with other wheels is now possible. Grinding can be performed at the same feed rate as for Si wafers and ultra-smooth surfaces can be produced.

| Applications | Ultra-precision surface grinding of various semiconductor wafers |

|---|

Brittle LT wafers used for SAW filters can be ground with low damage and high quality.

| Applications | Precision surface grinding of LT wafers |

|---|

This wheel demonstrates excellence in reducing damaged layers and strain layers during grinding of brittle materials such as reducing polishing of 300-mm silicon wafers and minimizing cracking of thin device wafers.

| Applications | Ultra-precision surface grinding of various semiconductor wafers |

|---|

The grain layer has been formed and sintered in a ring shape to provide uniform performance on the entire wheel circumference to improve the truing accuracy significantly.

| Applications | Industry/ Automobiles, bearings, tools, gears; Application/ Mass production parts grinding; Workpiece/ Cams, crankshafts, injection needles, rocker arms, turbo parts, compressor parts, bearings, linear bearings, ball screws |

|---|

The adjustment of the binding grade and bond has enabled grinding of difficult-to-cut materials with fine grains that have been difficult to grind with conventional wheels.

| Applications | Precision surface grinding of GaN wafers |

|---|

| Applications | Precision surface grinding of Sapphire wafers |

|---|

- Please contact below for Inquiries about diamond tools/ CBN tools