Molybdenum rods

High-performance grades are available for furnace components, heaters, etc.

It is available not only as molybdenum wires but also as bars. Leveraging its high melting point and easier processability compared to tungsten, molybdenum wires are primarily used for high-temperature furnace components. Various wire diameters and finishes can be provided to suit specific applications. Additionally, we offer materials with enhanced performance through the addition of trace elements (TEM), benefiting from our integrated production system from raw materials to finished products.

| Applications | Lightings, Electrodes, High-temperature furnace components, Probe pins, etc. |

|---|

Materials guide

| MOP | It is the most conventional pure molybdenum material, exhibiting a high melting point, high-temperature strength, good thermal conductivity, a low coefficient of thermal expansion, and excellent workability. |

|---|---|

| MOS | The MOS type improved coiling properties and an working range, achieved through adjustments to the composition at the raw material stage. |

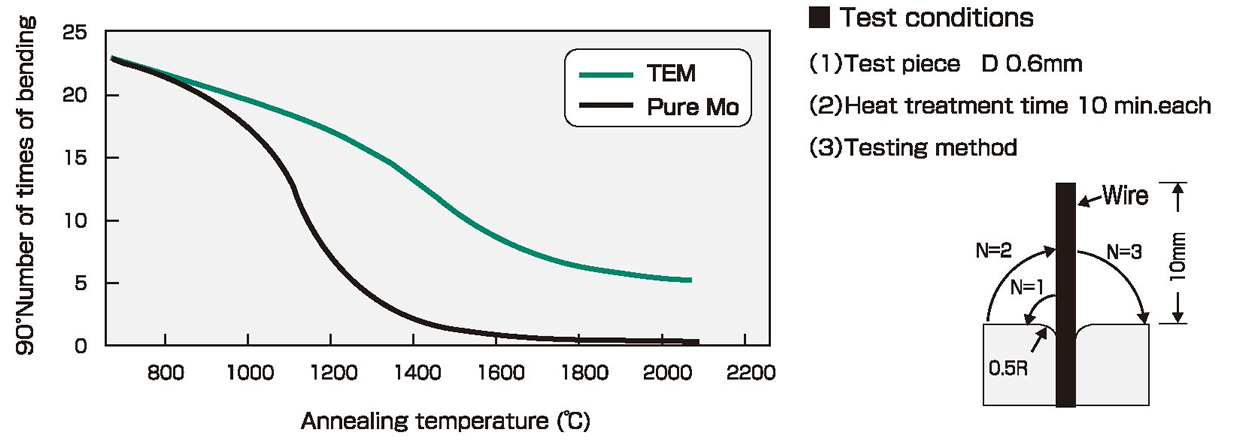

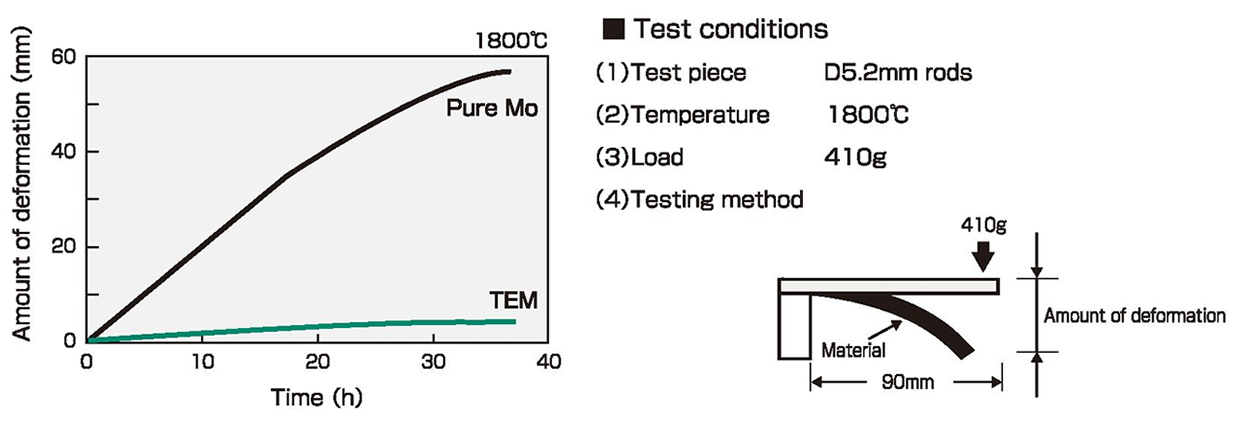

| TT-TEM™ | This high-quality molybdenum material overcomes the brittleness and high-temperature deformation issues associated with conventional molybdenum. It exhibits excellent high-temperature deformation resistance, a high recrystallization temperature, and a wedge-shaped recrystallized structure. Even after high-temperature use, it retains excellent impact resistance and remains deformable at room temperature, offering greater bendability than pure molybdenum. |

| TZM | Molybdenum with added Ti, Zr, and C. It has a high recrystallization temperature, high-temperature strength, and excellent creep resistance. It is used for forging tools and rotating anodes of X-ray tubes. |

スクロールで表全体をご覧いただけます。

| Type | Applications | Non-sag | Shock resistance |

Machinability | Abrasion resistance |

|---|---|---|---|---|---|

| MOP | Structural heaters, Bolts, Nuts | Average | Good | Excellent | Excellent |

| MOS | Grids, Mandrels, Anchors | Good | Good | Excellent | Good |

| TT-TEM™ | Supports, Heaters, Bolts, Nuts, Supporting shafts for X-ray tubes | Excellent | Excellent | Excellent | Good |

| TZM | Forging tools, Furnace components | Good | Excellent | Excellent | Excellent |

Standard specifications of molybdenum rods

スクロールで表全体をご覧いただけます。

| Diameter range (mm) More than - Less than |

Type | Finish | Tolerance diameter (mm) |

Finish grinding *1 |

Tolerance diameter (mm) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| MOP | MOS | TT-TEM™ | TZM | Drawn, Swaged |

Electrolytic polished |

Chemical cleaned |

||||

| 0.02~0.20 | ✓ | ✓ | ✓ | ±0.005 | ||||||

| 0.20~0.40 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ||||

| 0.40~0.50 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.01 | ||||

| 0.50~0.60 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.02 | ||||

| 0.60~0.80 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ||||

| 0.80~1.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ✓ | |||

| 1.0~1.5 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.02 | ||

| 1.5~2.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.02 | ||

| 2.0~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.03 | ||

| 3.0~4.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | ||

| 4.0~4.6 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | ||

| 4.6~5.0 | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | |||

| 5.0~6.4 | ✓ | ✓ | ✓ | ✓ | ±0.2 | ✓ | ±0.05 | |||

| 6.4~8.6 | ✓ | ✓ | ✓ | ✓ | ±0.25 | ✓ | ±0.05 | |||

| 8.6~12.0 | ✓ | ✓ | ✓ | ±0.3 | ✓ | ±0.05 | ||||

| 12.0~15.0 | ✓ | ✓ | ✓ | ±0.4 | ✓ | ±0.1 | ||||

| 15.0~22.0 | ✓ | ✓ | ✓ | ±0.5 | ✓ | ±0.15 | ||||

| 22.0~26.0 | ✓ | ✓ | ✓ | ✓ | ±0.6 | ✓ | ±0.15 | |||

| 26.0~28.0 | ✓ | ✓ | ✓ | ✓ | ±0.7 | ✓ | ±0.2 | |||

| 28.0~50.0 | ✓ | ✓ | ✓ | ✓ | ±1.0 | ✓ | ±0.2 | |||

*1 Finish grinding: Centerless grinding for diameters less than 30 mm. and cutting-belt grinding for diameters of 30 mm and larger.

*2 For products with a diameter of 50 mm or greater, please contact us.

Purity of molybdenum wires and rods

| Type | Purity(%) |

|---|---|

| MOP, MOS | 99.95 min. |

| TT-TEM™, TZM | 99.00 min. |

Bending ability of TT-TEM rods

Excellent high-temperature deformation resistance of TT-TEM rods, and examples of heater use

- Molybdenum technical information