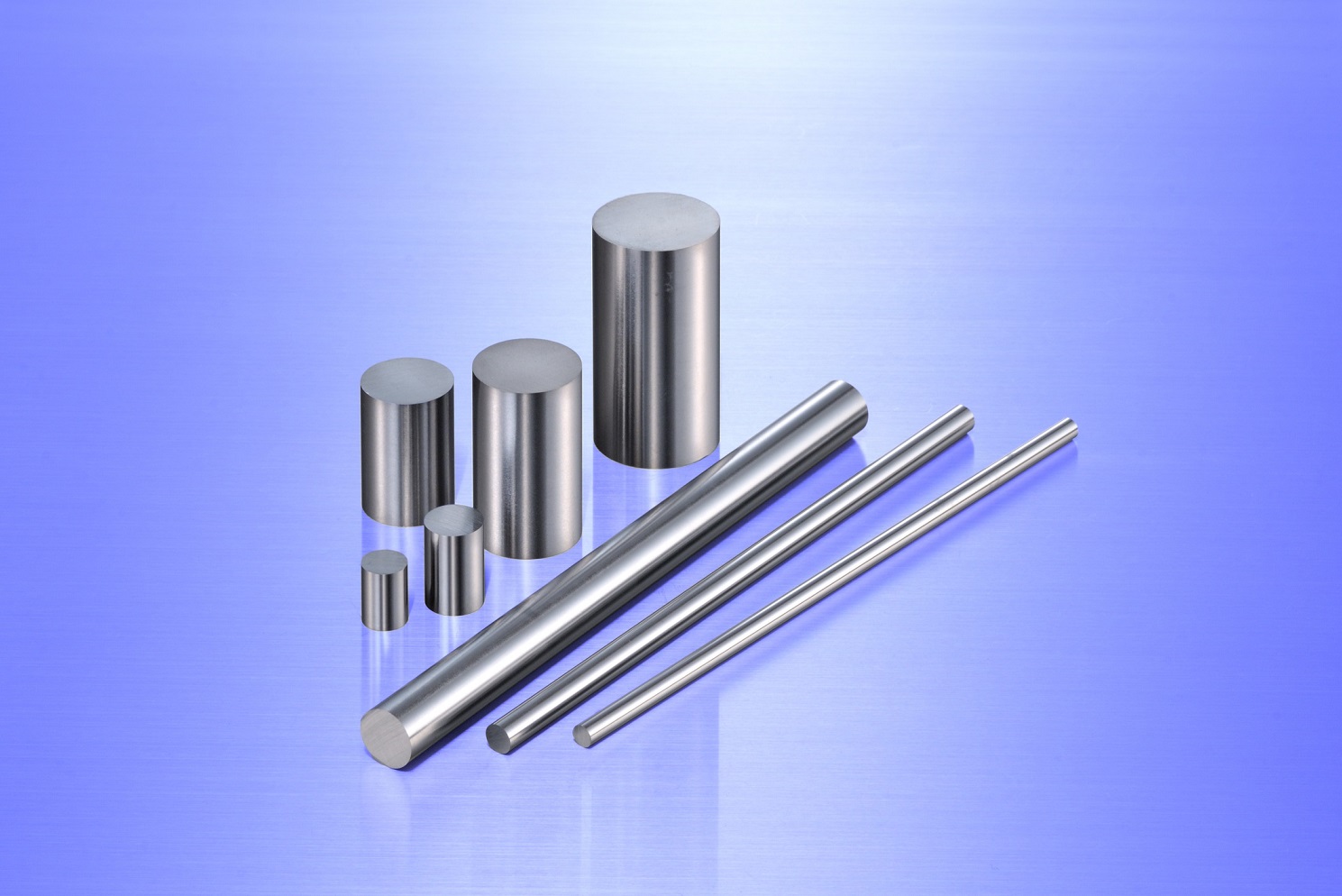

Tungsten rods

For lighting, electrodes, and components of high-temperature furnaces.

We can provide tungsten wires and rods. Leveraging its characteristic as the metal with the highest melting point, tungsten wires are utilized for lighting, electrodes, high-temperature furnace parts, probe pins, etc. Various wire diameters, materials, and finishes are available to meet your specifications. We also offer tungsten rods with the world’s highest purity, achieved through strict control of raw materials and processes, benefiting from our integrated production system.

| Applications | Lighting, Electrodes, High-temperature furnace components, Probe pins, etc. |

|---|

Materials guide

| AW | It exhibits excellent resistance to high-temperature deformation, blackening, and shock, ensuring a long service life due to its low content of impurity gases. |

|---|---|

| AX | Compared to conventional materials, the recrystallization temperature is 50 to 200℃ higher, the doped pores are smaller, and the crystal structure length after recrystallization is 3 to 4 times longer, significantly improving nonsagging properties. |

| EX | It contains minimal impurity gases and demonstrates excellent resistance to high-temperature deformation and corrosion from deposited metals such as Al, Ni, and Cr. This ensures a long service life, making it one of the world’s premier filament materials. |

| DW | Long-life tungsten facilitates thermal electron generation and prevents grain growth and grain boundary cracking at thermal electron emission temperatures. Coil processing, tip processing, and assembly processing are also available upon request. |

| CY(PFW) | This is the most common pure tungsten material, exhibiting good workability, excellent corrosion resistance, and low impurity gas content. |

| EP, KT | The fine dispersion of crystal grains significantly reduces the resistance to discharge consumption. |

| 4N-W | Tungsten with reduced impurities, achieving a purity of 99.99% or higher. |

5N-W |

This is the world’s highest purity tungsten, achieving a purity of 99.999% or higher by reducing impurities to the utmost limit. in various discharge lamps and in advanced technology fields where minimal impurity levels are critical. |

| LW | Tungsten with added La. Because La is finely dispersed, it has excellent workability. LW material is used for ion sources, lamp electrodes, and other applications because its electron work function is lower than that of pure tungsten. |

スクロールで表全体をご覧いただけます。

| Type | Applications | Non-sag | Shock resistance |

Machinability | Dischargeability | Discharge consumption resistance | Abrasion resistance | Corrosion resistance (VM) |

|---|---|---|---|---|---|---|---|---|

| AW | Filaments for halogen lamps, Grids, Supports, Heaters, Electrified wires | Excellent | Good | Good | Average | Good | Good | Average |

| AX | Filaments for ultra high temperature halogen lamps (for thick and medium wires) | Excellent | Excellent | Excellent | Average | Good | Good | Average |

| EX | Vacuum deposition, High-temperature furnace heaters, Printer printing wires, Supports, Discharge electrodes, Probe pins | Good | Good | Excellent | Average | Excellent | Excellent | Excellent |

| DW | Electrodes, charged wire thermal electron emission filaments | Good | Excellent | Excellent | Excellent | Excellent | Good | Average |

| CY (PFW) |

Structural and furnace heaters | Average | Average | Excellent | Average | Average | Good | Excellent |

| EP | Discharge electrodes, Structural materials,

welding Welding electrodes |

Good | Average | Excellent | Average | Excellent | Excellent | Average |

| KT | Discharge electrodes, Structural materials | Good | Average | Excellent | Average | Excellent | Excellent | Average |

| 4N-W 5N-W |

Electrodes, Heaters | Average | Average | Excellent | Average | Good | Excellent | Good |

| LW | Structural materials, discharge electrodes, | Good | Excellent | Excellent | Good | Good | Good | Average |

Standard specifications of tungsten rods

スクロールで表全体をご覧いただけます。

| Diameter range (mm) More than - Less than |

Type | Finish | Tolerance diameter (mm) |

Finish grinding *1 |

Tolerance diameter (mm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AW | AX | EX | CY PFW |

4N-W 5N-W |

EP KT |

LW | Drawn, Swaged |

Electrolytic Polished |

Chemical Cleaned |

||||

| ~0.15 | ✓ | ✓ | ✓ | ±0.005 | |||||||||

| 0.15~0.20 | ✓ | ✓ | ✓ | ±0.005 | |||||||||

| 0.20~0.40 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ||||||

| 0.40~0.50 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.01 | ||||||

| 0.50~0.60 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.02 | ||||||

| 0.60~0.80 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | |||||

| 0.80~1.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ✓ | ±0.03 | ||||

| 1.0~1.3 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ✓ | ±0.03 | |||||

| 1.3~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.03 | |||||

| 3.0~5.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | ||||

| 5.0~6.4 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.2 | ✓ | ±0.05 | ||||

| 6.4~8.6 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.25 | ✓ | ±0.1 | ||||

| 8.6~12.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.3 | ✓ | ±0.1 | |||||

| 12.0~15.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.4 | ✓ | ±0.1 | |||||

| 15.0~18.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.5 | ✓ | ±0.15 | ||||

| 18.0~(40.0) | ✓ | ✓ | ✓ | ✓ | ✓ | ±1.0 | ✓ | ±0.2 | |||||

*1 Finish grinding: Centerless grinding for diameters less than 30 mm, and cutting-belt grinding for diameters of 30 mm and larger.

Manufacturable range and standard tolerances for Tungsten rod lengths

スクロールで表全体をご覧いただけます。

| Diameter (mm) | Standard length (tolerance) :mm | Max length (tolerance) :mm |

|---|---|---|

| 5 | 1,000 (+10/0) | 11,000 (±50) |

| 6 | 1,000 (+10/0) | 7,500 (±50) |

| 8 | 1,100 (+10/0) | 4,000 (±50) |

| 11 | 1,000 (+10/0) | 3,000 (±50) |

| 16 | 1,200 (+10/0) | 1,500 (±50) |

| 21 | 1,100 (+10/0) | 1,500 (+10/0) |

| 25 | 850 (+5/0) | 1,500 (+10/0) |

| 31 | 700 (+5/0) | 1,400 (+10/0) |

| 36 | 500 (+5/0) | 1,000 (+10/0) |

| 41 | 400 (+4/0) | 800 (+5/0) |

| 45 | 300 (+4/0) | 600 (+5/0) |

| 50 | 230 (+3/0) | 450 (+4/0) |

please contact us for dimensions other than those mentioned above.

Purity of tungsten rods

| Type | Purity(%) |

|---|---|

| AW, AX, EX, CY, EP, KT | 99.95 min. |

| DW | 99.00 min. |

| LW | 97.00 min. |

| 4N-W | 99.99 min. |

| 5N-W | 99.999 min. |

- Tungsten technical information