Drilled and bent products

High-precision machining using the latest processing technology

With our in-house facilities, we are capable of producing tungsten and molybdenum products that involve drilling, bending, caulking, and more, with high precision. Please contact us through the inquiry link below with details of your required dimensions, processing and finishing methods, as well as other specifications and intended applications. We are also able to accommodate small-lot production requests for prototyping purposes.

| Applications |

Structural components for semiconductor manufacturing equipment, Trays for high-temperature furnaces, etc. |

|---|

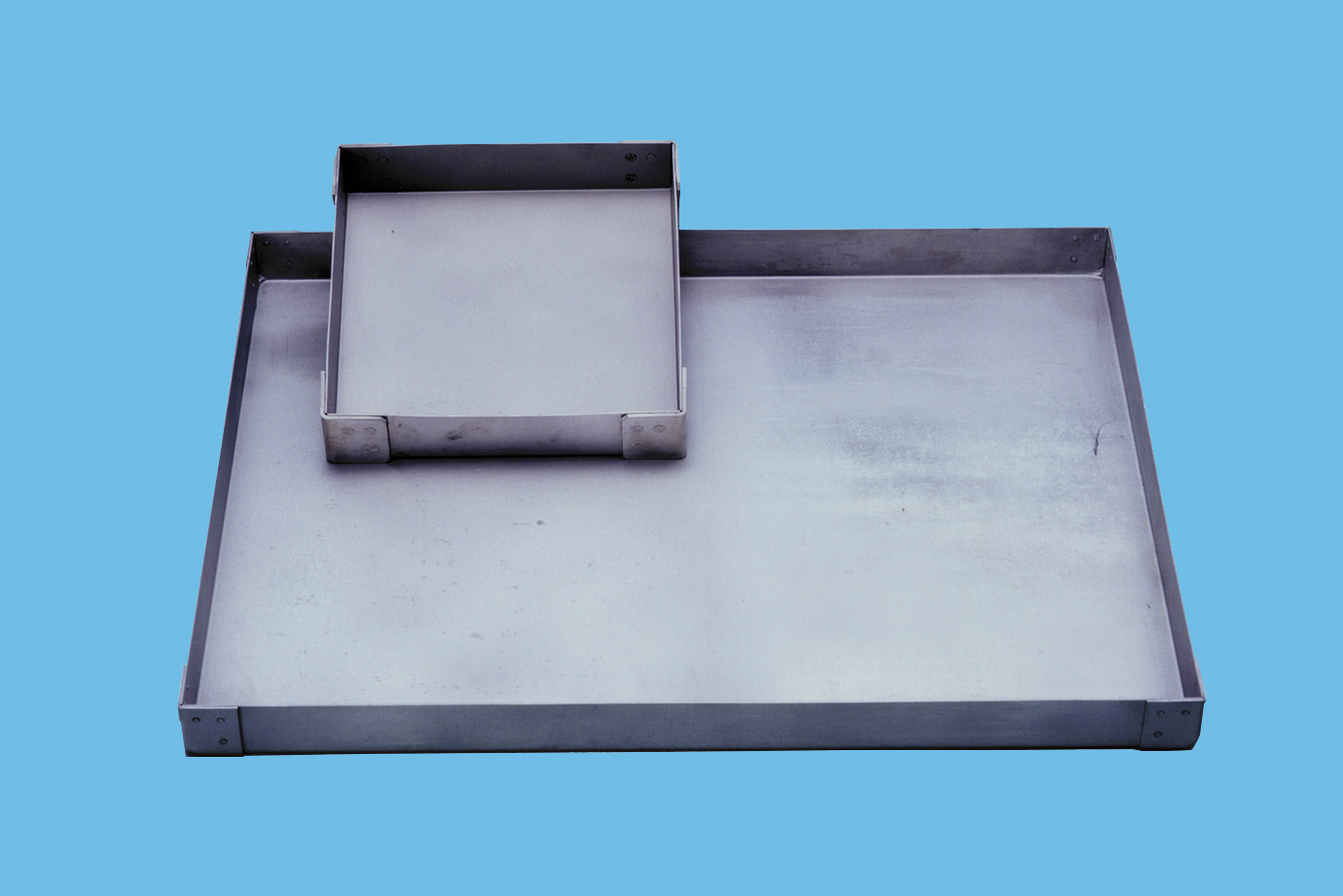

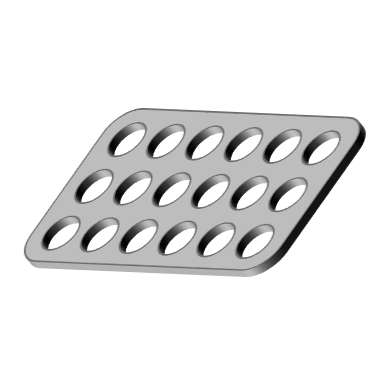

Example of processed shapes

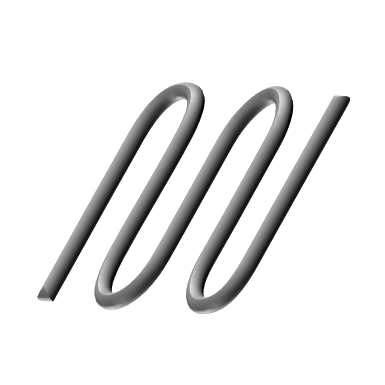

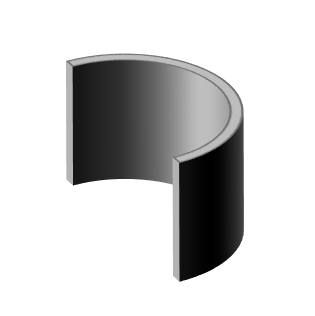

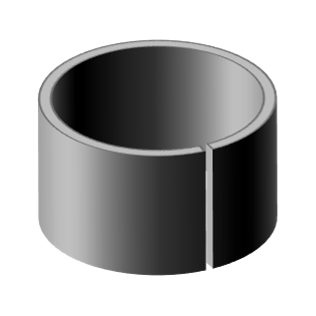

| Porous shape | Tray shape | Plate bending shape | Wire and bar bending shapes |

|---|---|---|---|

|

|

|

|

| Curved plate shape | Tube or cup shape | Taper shape |

|---|---|---|

|

|

|

Tungsten wires and rods materials guide

スクロールで表全体をご覧いただけます。

| Type | Applications | Non-sag | Shock resistance |

Machinability | Dischargeability | Discharge consumption resistance | Abrasion resistance | Corrosion resistance (VM) |

|---|---|---|---|---|---|---|---|---|

| AW | Filaments for halogen lamps, Grids, Supports, Heaters, Electrified wires | Excellent | Good | Good | Average | Good | Good | Average |

| AX | Filaments for ultra high temperature halogen lamps (for thick and medium wires) | Excellent | Excellent | Excellent | Average | Good | Good | Average |

| EX | Vacuum deposition, High-temperature furnace heaters, Printer printing wires, Supports, Discharge electrodes, Probe pins | Good | Good | Excellent | Average | Excellent | Excellent | Excellent |

| DW | Electrodes, Charged wire thermal electron emission filaments | Good | Excellent | Excellent | Excellent | Excellent | Good | Average |

| CY (PFW) |

Structural and furnace heaters | Average | Average | Excellent | Average | Average | Good | Excellent |

| EP | Discharge electrodes, Structural materials,

welding Welding electrodes |

Good | Average | Excellent | Average | Excellent | Excellent | Average |

| KT | Discharge electrodes, Structural materials | Good | Average | Excellent | Average | Excellent | Excellent | Average |

| 4N-W 5N-W |

Electrodes, Heaters | Average | Average | Excellent | Average | Good | Excellent | Good |

| LW | Structural materials, discharge electrodes, | Good | Excellent | Excellent | Good | Good | Good | Average |

Standard specifications of tungsten wires

スクロールで表全体をご覧いただけます。

| Diameter range (mm) More than - Less than |

Type | Finish | Tolerance diameter (mm) |

Tolerance MG (%) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| AW | AX CY |

EX | DW | 4N-W 5N-W |

Drawn | Chemical Cleaned |

Electrolytic polished |

Straight and Cut |

|||

| 0.03~0.14 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ±2 | ||||

| 0.14~0.40 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ±2 | ||

| 0.40~0.50 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.01 | ±2 | ||

| 0.50~0.60 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.02 | |||

| 0.60~0.80 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ||

| 0.80~1.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ||||

| 1.0~1.2 | ✓ | ✓ | ✓ | ✓ | ±0.04 | ||||||

| 1.2~1.5 | ✓ | ✓ | ±0.04 | ||||||||

Standard specifications of tungsten rods

スクロールで表全体をご覧いただけます。

| Diameter range (mm) More than - Less than |

Type | Finish | Tolerance diameter (mm) |

Finish grinding *1 |

Tolerance diameter (mm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AW | AX | EX | CY PFW |

4N-W 5N-W |

EP KT |

LW | Drawn, Swaged |

Electrolytic Polished |

Chemical Cleaned |

||||

| ~0.15 | ✓ | ✓ | ✓ | ±0.005 | |||||||||

| 0.15~0.20 | ✓ | ✓ | ✓ | ±0.005 | |||||||||

| 0.20~0.40 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ||||||

| 0.40~0.50 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.01 | ||||||

| 0.50~0.60 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.02 | ||||||

| 0.60~0.80 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | |||||

| 0.80~1.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ✓ | ±0.03 | ||||

| 1.0~1.3 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ✓ | ±0.03 | |||||

| 1.3~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.03 | |||||

| 3.0~5.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | ||||

| 5.0~6.4 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.2 | ✓ | ±0.05 | ||||

| 6.4~8.6 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.25 | ✓ | ±0.1 | ||||

| 8.6~12.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.3 | ✓ | ±0.1 | |||||

| 12.0~15.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.4 | ✓ | ±0.1 | |||||

| 15.0~18.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.5 | ✓ | ±0.15 | ||||

| 18.0~(40.0) | ✓ | ✓ | ✓ | ✓ | ✓ | ±1.0 | ✓ | ±0.2 | |||||

*1 Finish grinding: Centerless grinding for diameters less than 30 mm, and cutting-belt grinding for diameters of 30 mm and larger.

Manufacturable range and standard tolerances for Tungsten rod lengths

スクロールで表全体をご覧いただけます。

| Diameter (mm) | Standard length (tolerance) :mm | Max length (tolerance) :mm |

|---|---|---|

| 5 | 1,000 (+10/0) | 11,000 (±50) |

| 6 | 1,000 (+10/0) | 7,500 (±50) |

| 8 | 1,100 (+10/0) | 4,000 (±50) |

| 11 | 1,000 (+10/0) | 3,000 (±50) |

| 16 | 1,200 (+10/0) | 1,500 (±50) |

| 21 | 1,100 (+10/0) | 1,500 (+10/0) |

| 25 | 850 (+5/0) | 1,500 (+10/0) |

| 31 | 700 (+5/0) | 1,400 (+10/0) |

| 36 | 500 (+5/0) | 1,000 (+10/0) |

| 41 | 400 (+4/0) | 800 (+5/0) |

| 45 | 300 (+4/0) | 600 (+5/0) |

| 50 | 230 (+3/0) | 450 (+4/0) |

please contact us for dimensions other than those mentioned above.

Purity of tungsten rods

| Type | Purity(%) |

|---|---|

| AW, AX, EX, CY, EP, KT | 99.95 min. |

| DW | 99.00 min. |

| LW | 97.00 min. |

| 4N-W | 99.99 min. |

| 5N-W | 99.999 min. |

Tungsten sheets / plates materials guide

スクロールで表全体をご覧いただけます。

| Materials | Applications | Type | Machinability | Bend formability | Impact resistance | Sputtering | Density |

|---|---|---|---|---|---|---|---|

| 3N-W | Base plates for sintering, Boats, Heaters, Reflectors, Heat spreader materials, Weights, Spacers, Various jigs and tools | Rolled products |

Excellent | Excellent | Good | Excellent | Excellent |

| 4N-W | Sputtering target materials, Hot press molds | Rolled products |

Excellent | Excellent | Good | Excellent | Excellent |

| 5N-W | Sputtering target materials | Rolled products |

Excellent | Excellent | Good | Excellent | Excellent |

Types of tungsten plates

| Materials | purity (%) |

|---|---|

| 3N-W(General) | 99.95 min. |

| 4N-W(High purity) | 99.99 min. |

| 5N-W(Ultrahigh purity) | 99.999 min. |

| Type | Density (g/cm3) | Relative density (%) |

|---|---|---|

| Rolled products |

18.6~19.3 | 96.3~100.0 |

Tungsten sheets / plates fabrication range and tolerances

スクロールで表全体をご覧いただけます。

| Thickness (mm) More than - Less than |

Finished surface | Size (mm) | Tolerance Width / Length (mm) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Rolled | Mirror | CC | Cutting | Polishing | Horning | Max width | Max length | ||

| 0.4~0.5 | ✓ | ✓ | ✓ | ✓ | 100 | 500 | - | ||

| 0.5~1.0 | ✓ | ✓ | ✓ | ✓ | 300 | 500 | - | ||

| 1.0~1.5 | ✓ | ✓ | ✓ | ✓ | ✓ | 300 | 500 | ±2.0 | |

| 1.5~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | 300 | 500 | ±3.0 | |

| 3.0~5.0 | ✓ | ✓ | ✓ | ✓ | ✓ | 500 | 2,000 | ±3.0 | |

| 5.0~11.0 | ✓ | ✓ | ✓ | ✓ | ✓ | 500 | 1,000 | ±3.0 | |

* For over 10 mm, please contact us for further details.

Molybdenum wires and rods materials guide

スクロールで表全体をご覧いただけます。

| Type | Applications | Non-sag | Shock resistance | Machinability | Abrasion resistance |

|---|---|---|---|---|---|

| MOP | Structural, Heaters, Bolts, Nuts | Average | Good | Excellent | Excellent |

| MOS | Grid, Mandrel, Anchors | Good | Good | Excellent | Good |

| TEM | Supports, Heater, Bolts, Nuts, Supporting shafts X-ray tubes | Excellent | Excellent | Excellent | Good |

| TZM | Forging tools, Furnace components | Good | Excellent | Excellent | Excellent |

Standard specifications of molybdenum wire

スクロールで表全体をご覧いただけます。

| Diameter range (mm) More than - Less than |

Type | Finish | Tolerance diameter (mm) |

Tolerance MG (%) |

||||

|---|---|---|---|---|---|---|---|---|

| MOP | MOS | TT-TEM™ | Drawn | Annealed | Electrolytic polished |

|||

| 0.02~0.18 | ✓ | ✓ | ✓ | ✓ | ±0.005 | ±3 | ||

| 0.18~0.20 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ±3 |

| 0.20~0.40 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ±2 |

| 0.40~0.50 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.01 | ±2 |

| 0.50~0.60 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.02 | |

| 0.60~0.80 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | |

| 0.80~1.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | |

| 1.0~1.5 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.04 | |

| 1.5~2.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ||

| 2.0~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ||

| 3.0~4.0 | ✓ | ✓ | ✓ | ✓ | ±0.05 | |||

Standard specifications of molybdenum rods

スクロールで表全体をご覧いただけます。

| Diameter range (mm) More than - Less than |

Type | Finish | Tolerance diameter (mm) |

Finish grinding *1 |

Tolerance diameter (mm) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| MOP | MOS | TT-TEM™ | TZM | Drawn, Swaged |

Electrolytic polished |

Chemical cleaned |

||||

| 0.02~0.20 | ✓ | ✓ | ✓ | ±0.005 | ||||||

| 0.20~0.40 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.005 | ||||

| 0.40~0.50 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.01 | ||||

| 0.50~0.60 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.02 | ||||

| 0.60~0.80 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ||||

| 0.80~1.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.03 | ✓ | |||

| 1.0~1.5 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.02 | ||

| 1.5~2.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.02 | ||

| 2.0~3.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.05 | ✓ | ±0.03 | ||

| 3.0~4.0 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | ||

| 4.0~4.6 | ✓ | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | ||

| 4.6~5.0 | ✓ | ✓ | ✓ | ✓ | ±0.15 | ✓ | ±0.03 | |||

| 5.0~6.4 | ✓ | ✓ | ✓ | ✓ | ±0.2 | ✓ | ±0.05 | |||

| 6.4~8.6 | ✓ | ✓ | ✓ | ✓ | ±0.25 | ✓ | ±0.05 | |||

| 8.6~12.0 | ✓ | ✓ | ✓ | ±0.3 | ✓ | ±0.05 | ||||

| 12.0~15.0 | ✓ | ✓ | ✓ | ±0.4 | ✓ | ±0.1 | ||||

| 15.0~22.0 | ✓ | ✓ | ✓ | ±0.5 | ✓ | ±0.15 | ||||

| 22.0~26.0 | ✓ | ✓ | ✓ | ✓ | ±0.6 | ✓ | ±0.15 | |||

| 26.0~28.0 | ✓ | ✓ | ✓ | ✓ | ±0.7 | ✓ | ±0.2 | |||

| 28.0~50.0 | ✓ | ✓ | ✓ | ✓ | ±1.0 | ✓ | ±0.2 | |||

*1 Finish grinding: Centerless grinding for diameters less than 30 mm. and cutting-belt grinding for diameters of 30 mm and larger.

*2 For products with a diameter of 50 mm or greater, please contact us.

Purity of molybdenum wires and rods

| Type | Purity(%) |

|---|---|

| MOP, MOS | 99.95 min. |

| TT-TEM™, TZM | 99.00 min. |

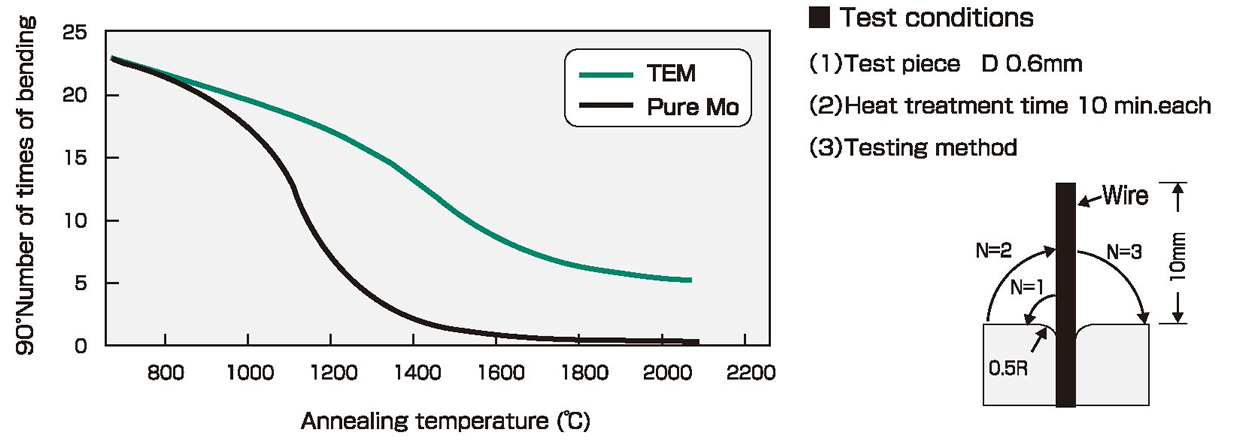

Bending ability of TT-TEM rods

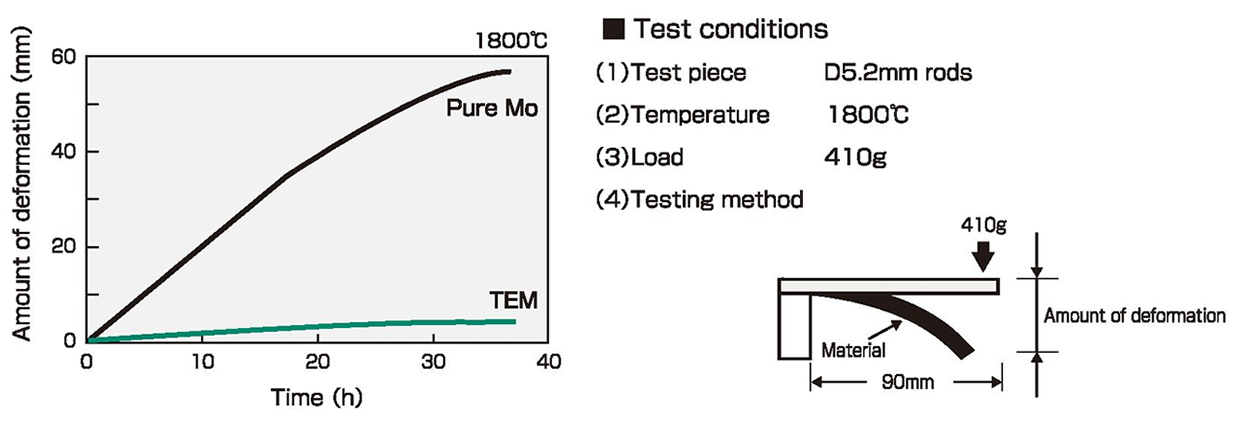

Excellent high-temperature deformation resistance of TT-TEM rods, and examples of heater use

Molybdenum sheets / plates materials guide

スクロールで表全体をご覧いただけます。

| Type | Applications | Type | High temperature deformation resistance | Shock resistance | Bending ability | Drawing ability | Cutting ability |

|---|---|---|---|---|---|---|---|

| MOP | Heat spreader materials, Boats for deposition, Electron tubes, Furnace components, Crucibles | Standard | Average | Good | Good | Good | Excellent |

| Materials for deep drawing, Boats for evaporation coating | Cross-rolled | Average | Good | Excellent | Excellent | Excellent | |

| TT-TEM™ | Reflectors | Standard | Good | Excellent | Good | Good | Good |

| TT-DMB™ | Baking Plates Anti-welding anvils Pedestal plates Boats |

Acid washing Cutting Polishing Horning Coating |

Excellent | Average | Average | Average | Good |

| TT-TEM™-B | Excellent | Good | Excellent | Good | Average | ||

| TT-TEM™ | Acid washing Cutting Polishing |

Good | Excellent | Good | Average | Good | |

| TZM | Good | Excellent | Good | Average | Good |

Manufacturable range of Molybdenum sheets / plates

スクロールで表全体をご覧いただけます。

| Type | Thickness (mm) More than - Less than |

Finished surface | Sizes (mm) | |||

|---|---|---|---|---|---|---|

| Mirror | Acid washing | Horning | Width (Max) | Length (Max) | ||

| MOP | 0.015~0.1 *2 | ✓ | 110 | 500 | ||

| 0.1~0.15 *2 | ✓ | 350 | 1,000 | |||

| 0.15~0.2 *2 | ✓ | ✓ | 350 | 1,000 | ||

| 0.2~3.0 *2 | ✓ | ✓ | 600 | 2,000 | ||

| 3.0~25.0 | ✓ | 600 (1,000) | 1,000 (3,000) | |||

| TT-TEM™*1 | 0.2~3.0 | ✓ | ✓ | 600 | 2,000 | |

| 3.0~25.0 | ✓ | 600 (1,000) | 1,000 (3,000) | |||

| TT-TEM™-B *1 | 0.5~1.5 | ✓ | ✓ | ✓ | 300 | 600 |

| 1.5~3.0 | ✓ | ✓ | ✓ | 500 | 600 | |

| 3.0~7.0 | ✓ | ✓ | 600 | 600 | ||

| TT-DMB™ | 1.5~3.0 | ✓ | ✓ | ✓ | 500 | 600 |

| 3.0~15.0 | ✓ | ✓ | 600 | 600 | ||

| TZM | 1.0~35.0 | ✓ | ✓ | ✓ | 600 | 1,000 |

*1: Products whose structure is controlled to prevent deformation at high temperature.

*2: Able to offer products with improved diaphragm workability.

*3: The number in parentheses is the maximum size of the rolled material.

Please contact us for dimensions other than those listed above.

Standard specifications of cross-rolled molybdenum sheets / plates (Unit: mm)

スクロールで表全体をご覧いただけます。

| Thickness General tolerance±10% (mm) |

Type | Finished surface | Sizes (mm) | |

|---|---|---|---|---|

| MOP | Mirror | Width (Max) | Length (Max) | |

| 0.10~1.00 | ✓ | ✓ | 300 | 1,000 |

* Cross-rolled material is available upon request. Plate thickness tolerance may vary depending on the finish.

Ceramic-coated molybdenum sheets / plates

Rather than traditional thick ceramics with low thermal efficiency, we produce molybdenum sheets and plates designed for protection against welding and reactions. Combined with ceramic coatings approximately 1/5 the thickness or less, these molybdenum sheets and plates enable more efficient furnace operations.

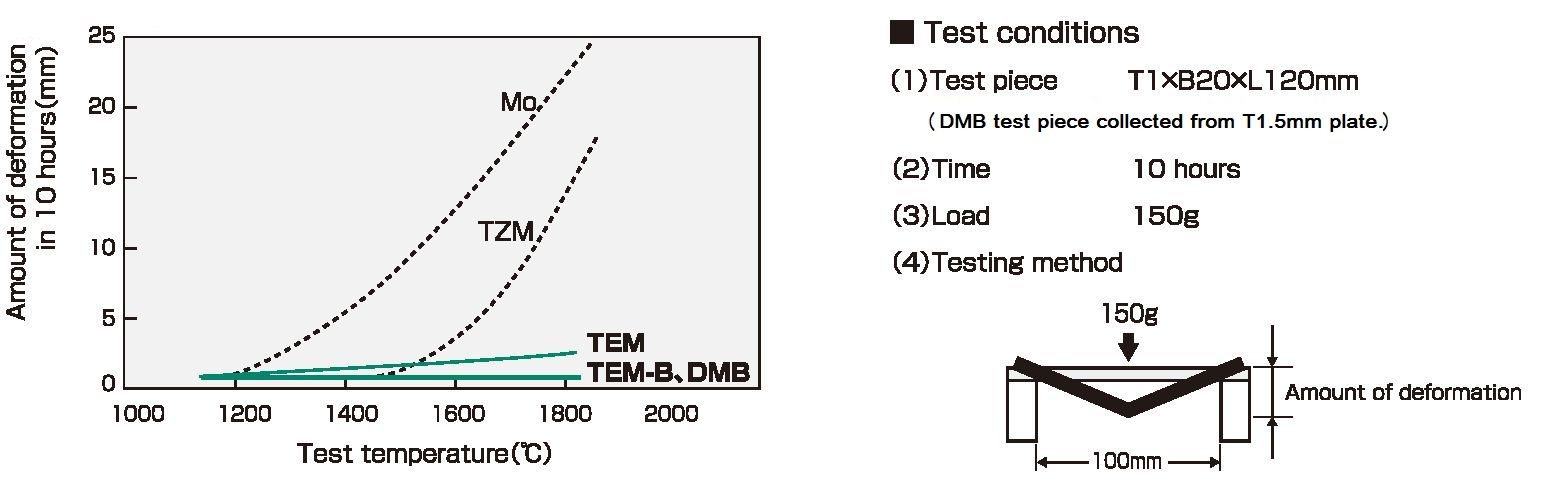

High-temperature deformation resistance of various kinds of molybdenum sheets / plates

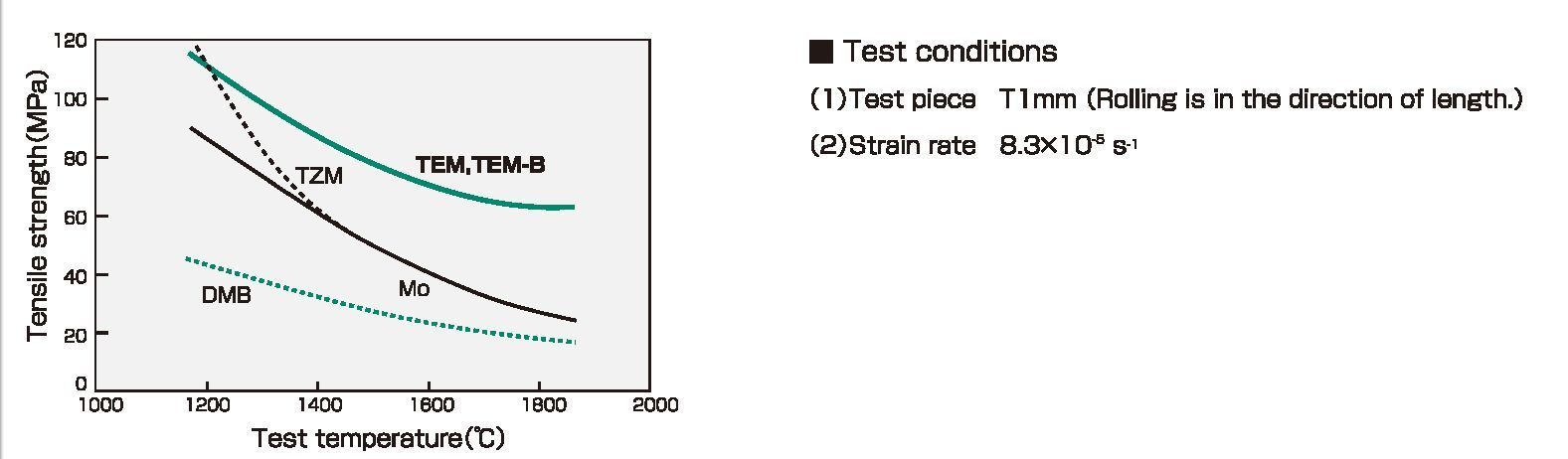

High-temperature strength of various kinds of molybdenum sheets / plates after use at high temperature (1,800℃)

- Tungsten technical information

- Molybdenum technical information