Molybdenum sheets / plates

Molybdenum sheets produced with our specialized rolling techniques

We produce a wide range of thick and thin sheets, leveraging our specialized rolling techniques. Molybdenum, known for its high melting point, is utilized in high-temperature furnace components, electrodes, and as a radiation shielding material due to its high specific gravity. Additionally, we supply the world’s highest-purity molybdenum sheets for sputtering targets, manufactured in-house from raw materials through an integrated process.

| Applications | X-ray shielding materials, structural components for furnaces, electrodes, etc. |

|---|

Materials guide

| MOP | This is the most conventional pure molybdenum material, exhibiting a high melting point, high-temperature strength, high thermal conductivity, low thermal expansion, and excellent processability. |

|---|---|

| TT-TEM™ | This high-quality molybdenum material overcomes the brittleness and high-temperature deformation issues of pure molybdenum by incorporating trace amounts of special elements. |

| TT-TEM™-B | This molybdenum material excels in high-temperature deformation resistance and room-temperature impact resistance, while also being capable of plastic deformation at room temperature. It offers greater high-temperature strength compared to pure molybdenum. By incorporating trace amounts of specialized elements, this material addresses the brittleness and high-temperature deformation challenges inherent to pure molybdenum. With exceptional high-temperature deformation resistance, a high recrystallization temperature, and a wedge-shaped recrystallized structure, it maintains impressive impact resistance even after high-temperature use. Furthermore, it boasts superior bendability at room temperature compared to pure molybdenum. |

| TT-DMB™ | It exhibits excellent deformation resistance at high temperatures, a low coefficient of thermal expansion, and outstanding properties in a vacuum or reducing atmosphere. |

| TZM | Molybdenum material that has additions of titanium, zirconium, carbon, and other elements offers higher high-temperature strength than pure molybdenum. |

スクロールで表全体をご覧いただけます。

| Type | Applications | Type | High temperature deformation resistance |

Shock resistance | Bending ability | Drawing ability | Cutting ability |

|---|---|---|---|---|---|---|---|

| MOP | Heat spreader materials, Boats for deposition, Electron tubes, Furnace components, Crucibles | Standard | Average | Good | Good | Good | Excellent |

| Materials for deep drawing, Boats for evaporation coating | Cross-rolled | Average | Good | Excellent | Excellent | Excellent | |

| TT-TEM™ | Reflectors | Standard | Good | Excellent | Good | Good | Good |

| TT-DMB™ | Baking Plates Anti-welding anvils Pedestal plates Boats |

Acid washing Cutting Polishing Honing Coating |

Excellent | Average | Average | Average | Good |

| TT-TEM™-B | Excellent | Good | Excellent | Good | Average | ||

| TT-TEM™ | Acid washing Cutting Polishing |

Good | Excellent | Good | Average | Good | |

| TZM | Good | Excellent | Good | Average | Good |

Manufacturable range of Molybdenum sheets / plates

スクロールで表全体をご覧いただけます。

| Type | Thickness (mm) More than - Less than |

Finished surface | Sizes (mm) | |||

|---|---|---|---|---|---|---|

| Mirror | Acid washing | Horning | Width (Max) | Length (Max) | ||

| MOP | 0.015~0.1 *2 | ✓ | 110 | 500 | ||

| 0.1~0.15 *2 | ✓ | 350 | 1,000 | |||

| 0.15~0.2 *2 | ✓ | ✓ | 350 | 1,000 | ||

| 0.2~3.0 *2 | ✓ | ✓ | 600 | 2,000 | ||

| 3.0~25.0 | ✓ | 600 (1,000) | 1,000 (3,000) | |||

| TT-TEM™*1 | 0.2~3.0 | ✓ | ✓ | 600 | 2,000 | |

| 3.0~25.0 | ✓ | 600 (1,000) | 1,000 (3,000) | |||

| TT-TEM™-B *1 | 0.5~1.5 | ✓ | ✓ | ✓ | 300 | 600 |

| 1.5~3.0 | ✓ | ✓ | ✓ | 500 | 600 | |

| 3.0~7.0 | ✓ | ✓ | 600 | 600 | ||

| TT-DMB™ | 1.5~3.0 | ✓ | ✓ | ✓ | 500 | 600 |

| 3.0~15.0 | ✓ | ✓ | 600 | 600 | ||

| TZM | 1.0~35.0 | ✓ | ✓ | ✓ | 600 | 1,000 |

*1: Products whose structure is controlled to prevent deformation at high temperature.

*2: Able to offer products with improved diaphragm workability.

*3: The number in parentheses is the maximum size of the rolled material.

Please contact us for dimensions other than those listed above.

Standard specifications of cross-rolled molybdenum sheets / plates (Unit: mm)

スクロールで表全体をご覧いただけます。

| Thickness General tolerance±10% (mm) |

Type | Finished surface | Size(mm) | |

|---|---|---|---|---|

| MOP | Mirror | Maximum width | Maximum length | |

| 0.10~1.00 | ✓ | ✓ | 300 | 1000 |

- Cross-rolled material is available upon request. Plate thickness tolerance may vary depending on the finish.

Ceramic-coated molybdenum sheets / plates

Rather than traditional thick ceramics with low thermal efficiency, we produce molybdenum sheets and plates designed for protection against welding and reactions. Combined with ceramic coatings approximately 1/5 the thickness or less, these molybdenum sheets and plates enable more efficient furnace operations.

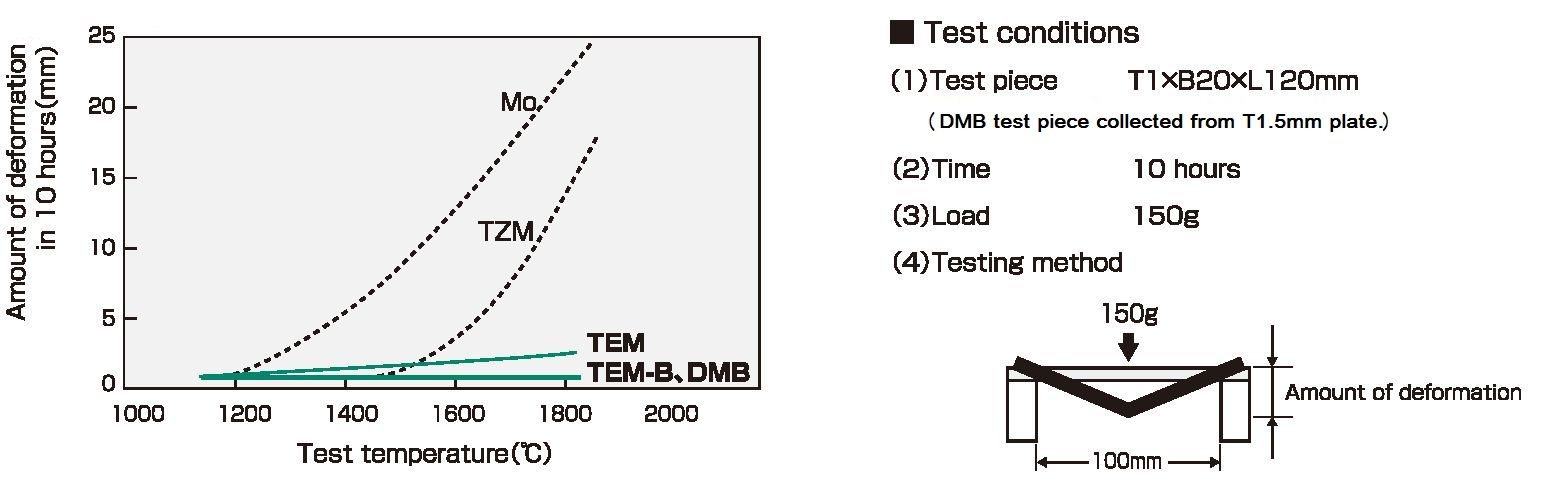

High-temperature deformation resistance of various kinds of molybdenum sheets / plates

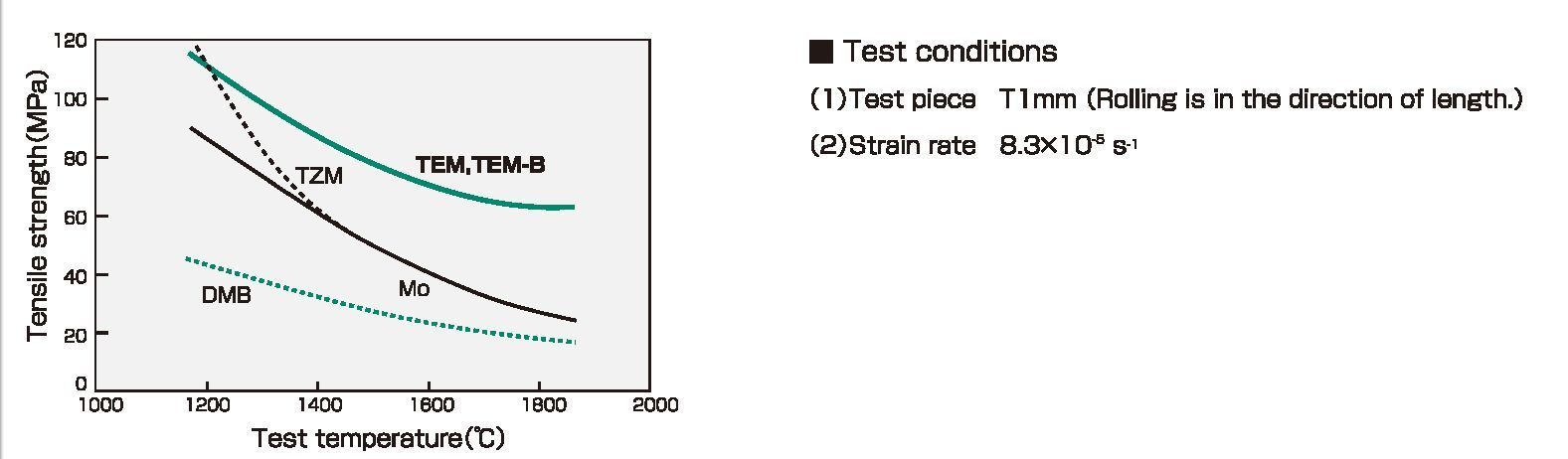

High-temperature strength of various kinds of molybdenum sheets / plates after use at high temperature (1,800℃)

- Molybdenum technical information