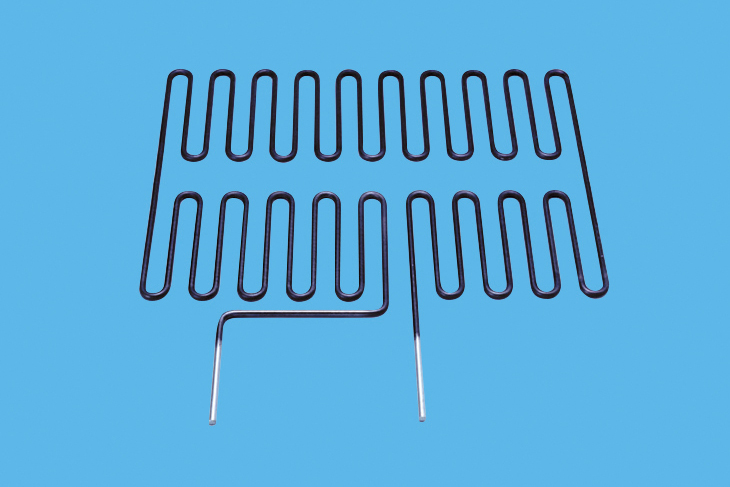

Heater for high-temperature furnace

Various machined components for vacuum furnaces and reduction atmosphere furnaces

Tungsten and molybdenum materials are essential for vacuum furnaces and reduction atmosphere furnaces. Utilizing our own tungsten and molybdenum materials, which exhibit excellent characteristics in high-temperature environments, we deliver products tailored to customer specifications. We not only follow products based on provided drawings but also offer design proposals to address issues and extend service life. Even without drawings, we can develop product designs to meet your needs. Our extensive experience includes manufacturing components for efficient high-temperature furnace operations, such as heaters for vacuum and reduction atmosphere furnaces, reflectors, ceramic parts, rare earth magnets, heaters for sintering nuclear fuel, trays, boats, and more.

| Applications | Components for high-temperature furnaces |

|---|

List of tungsten and molybdenum products for heaters

スクロールで表全体をご覧いただけます。

| W | Type | Purity(%) | Additive | Finish | Features |

|---|---|---|---|---|---|

| AW | 99.95 min. | K | Refer to Appendix 1 | It exhibits excellent resistance to high-temperature deformation, blackening, and seismic shock, providing a long service life due to its low content of impurity gases. | |

| AX | 99.95 min. | K | Compared to conventional materials, the recrystallization temperature is 50 to 200°C higher, doped pores are smaller, and the length of the crystal structure after recrystallization is 3 to 4 times longer, significantly improving nonsagging properties. | ||

| EX | 99.95 min. | K | It contains minimal impurity gases, exhibiting excellent resistance to high-temperature deformation and corrosion against deposited metals such as Al, Ni, and Cr, resulting in a long service life. | ||

| CY(PFW) | 99.95 min. | None | This is the most conventional pure tungsten material, which exhibits good workability, excellent corrosion resistance, and low impurity gas content. | ||

| 4N-W | 99.99 min. | None | High-purity tungsten material with reduced impurities. | ||

| 5N-W | 99.999 min. | None | It is one of the world's highest purity tungsten materials, featuring minimal impurities. |

スクロールで表全体をご覧いただけます。

| Mo | Type | Purity(%) | Additive | Finish | Features |

|---|---|---|---|---|---|

| MOP | 99.95 min. | None | Refer to Appendix 2 | This is the most conventional pure molybdenum material, exhibiting a high melting point and excellent high-temperature strength. It also has high thermal conductivity, low thermal expansion, and excellent workability. | |

| TT-TEM™ | 99.00 min. | Rare-Earth Oxides | This high-quality molybdenum material overcomes the brittleness and high-temperature deformation issues associated with conventional molybdenum. It exhibits excellent high-temperature deformation resistance, a high recrystallization temperature, and a wedge-shaped recrystallized structure. Even after high-temperature use, it remains excellent impact resistance and can be deformed at room temperature, offering greater bendability than pure molybdenum. |

Finish of tungsten heaters (appendix 1)

スクロールで表全体をご覧いただけます。

| Code | Finish |

|---|---|

| D | DRAWN |

| DS | DRAWN AND STRAIGHTENED |

| CC | CHEMICAL CLEANED |

| EE | ELECTROLYTIC ETCHED |

| EES | ELECTROLYTIC ETCHED AND STRAIGHTENED |

| EP | ELECTROLYTIC POLISHED |

| EPS | ELECTROLYTIC POLISHED AND STRAIGHTENED |

| EPSC | ELECTROLYTIC POLISHED AND STRAIGHTENED AND CUT |

| G | GROUND |

| S | SWAGED |

Finish of molybdenum heaters (appendix 2)

スクロールで表全体をご覧いただけます。

| Code | Finish |

|---|---|

| D | DRAWN |

| DSC | DRAWN AND STRAIGHTENED AND CUT |

| EE | ELECTROLYTIC ETCHED |

| EES | ELECTROLYTIC ETCHED AND STRAIGHTENED |

| EP | ELECTROLYTIC POLISHED |

| EPA | ELECTROLYTIC POLISHED AND ANNEALED |

| EPSC | ELECTROLYTIC POLISHED AND STRAIGHTENED AND CUT |

| G | GROUND |

| S | SWAGED |

| B | BELT GROUND |

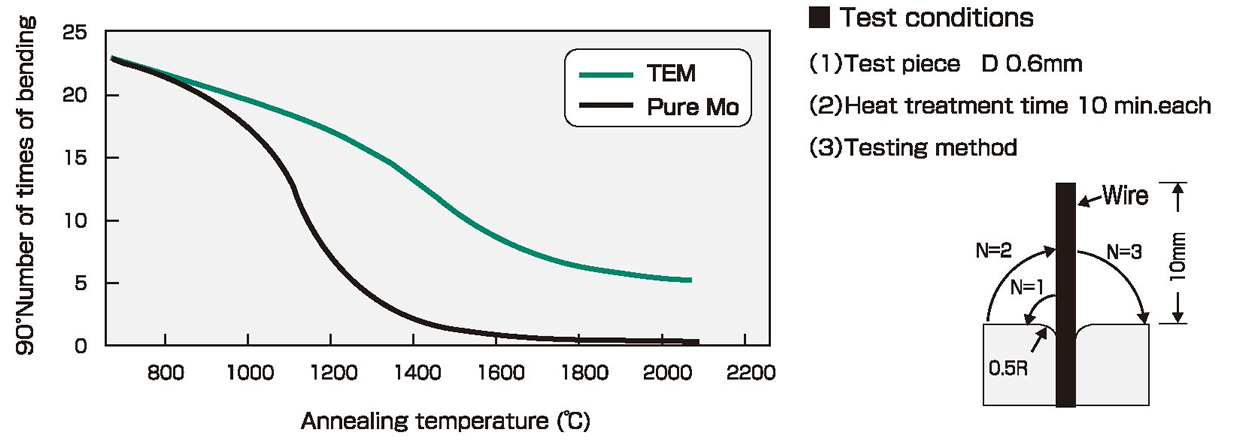

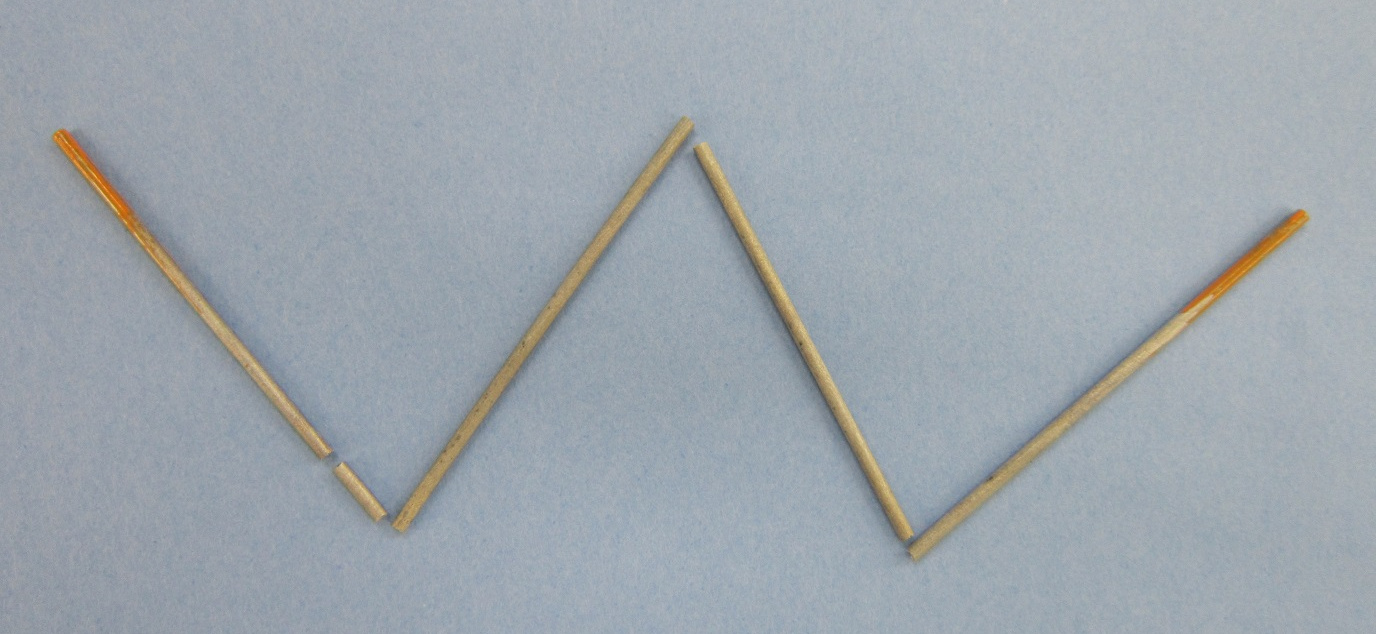

Bending ability of TT-TEM rods

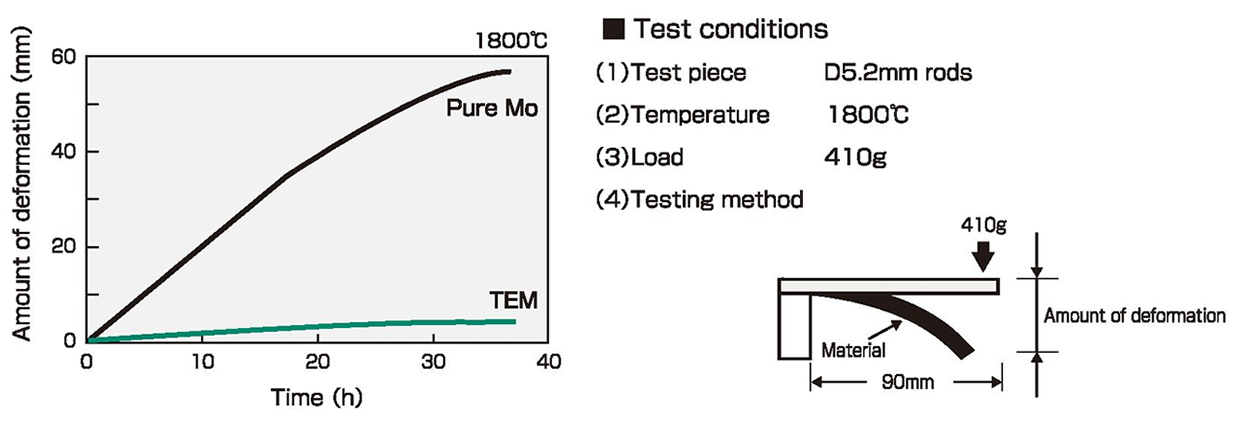

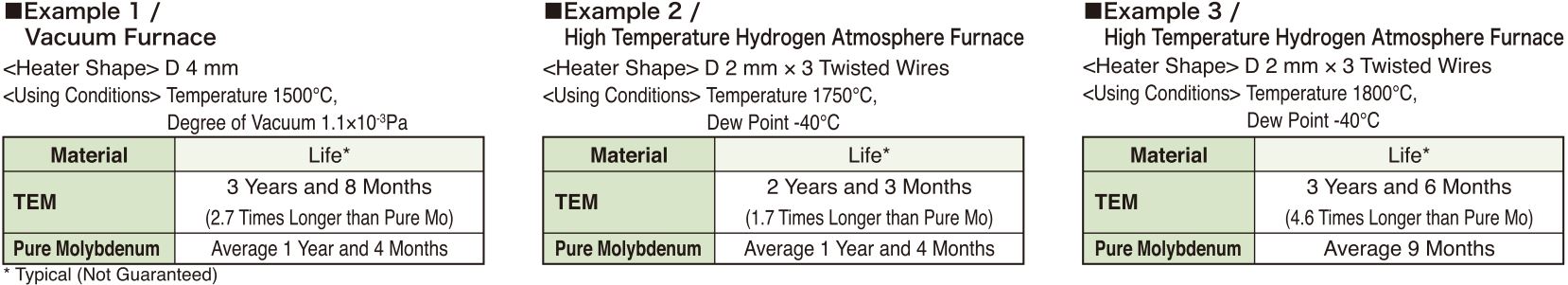

Excellent high-temperature deformation resistance of TT-TEM rods, and examples of heater use

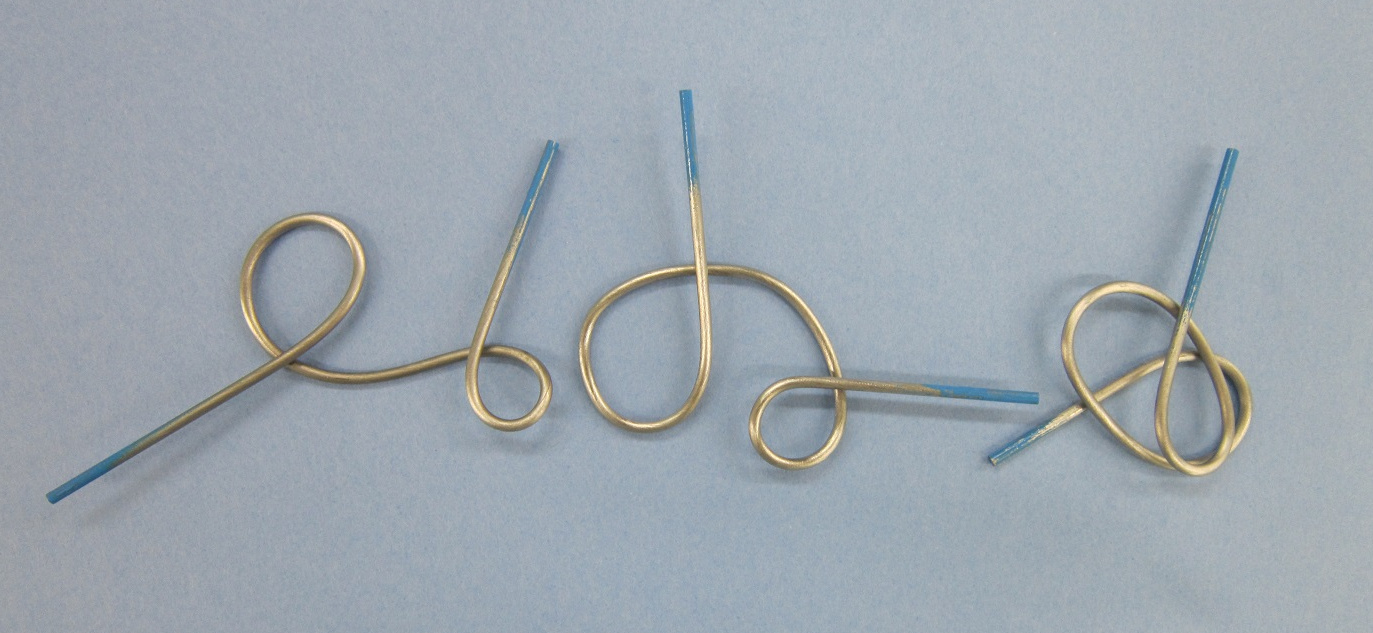

Comparison of bending of TT-TEM and pure Mo recrystallized rods

- TT-TEM recrystallized rods

- Pure Molybdenum recrystallized rods

Excellent high-temperature deformation resistance of TT-TEM rods,

and examples of heater use

- TT-TEM heater used for 3 years

- Pure Molybdenum heater used for 1.5 years

- Tungsten technical information

- Molybdenum technical information