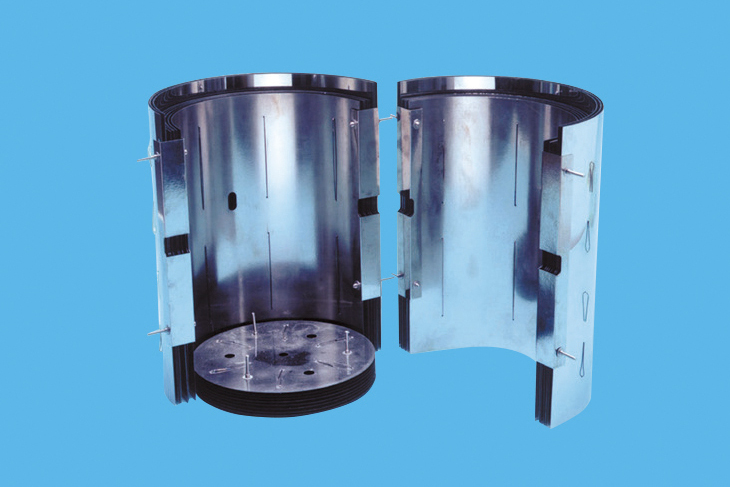

Reflector for high-temperature furnace

Reflectors for vacuum furnaces and reduction atmosphere furnaces

Tungsten and molybdenum materials are essential for vacuum furnaces and reduction atmosphere furnaces. By utilizing our proprietary tungsten and molybdenum materials, which exhibit excelent characteristics in high-temperature environments, we offer products that are designed and machined to meet customer specifications. We not only follow products based on provided drawings but also offer design proposals to address issues and extend service life. Even without drawings, we can develop product designs to meet your needs. With extensive experience in manufacturing components for high-temperature furnaces, we produce reflectors for high-temperature vacuum furnaces and reduction atmosphere furnaces, heaters, ceramic parts, rare earth magnets, sill plates, trays, and boats for sintering nuclear fuel and other materials, ensuring high-efficiency operation of high-temperature furnaces.

| Applications | Components for high-temperature furnaces |

|---|

List of Tungsten and Molybdenum products for reflectors

スクロールで表全体をご覧いただけます。

| W | Type | Purity(%) | Additive | Finish | Features |

|---|---|---|---|---|---|

| 3N-W | 99.95 min. | None | CC Cutting Polishing Horning |

This is the most conventional pure tungsten material, exhibiting good workability, excellent corrosion resistance, and low impurity gas content. | |

| 4N-W | 99.99 min. | None | High-purity tungsten material with reduced impurities. | ||

| 5N-W | 99.999 min. | None | This is the world's highest purity tungsten material, featuring minimal impurities. |

スクロールで表全体をご覧いただけます。

| Mo | Type | Purity(%) | Additive | Finish | Features |

|---|---|---|---|---|---|

| MOP | 99.95 min. | None | Mirror Acid Washing Cutting Polishing Horning Ceramic coat |

This is the most conventional pure molybdenum material, exhibiting a high melting point, high-temperature strength, high thermal conductivity, low thermal expansion, and excellent processability. | |

| TT-TEM™ | 99.00 min. | Rare-Earth Oxides | This high-quality molybdenum material overcomes the brittleness and high-temperature deformation issues of pure molybdenum by incorporating trace amounts of special elements. |

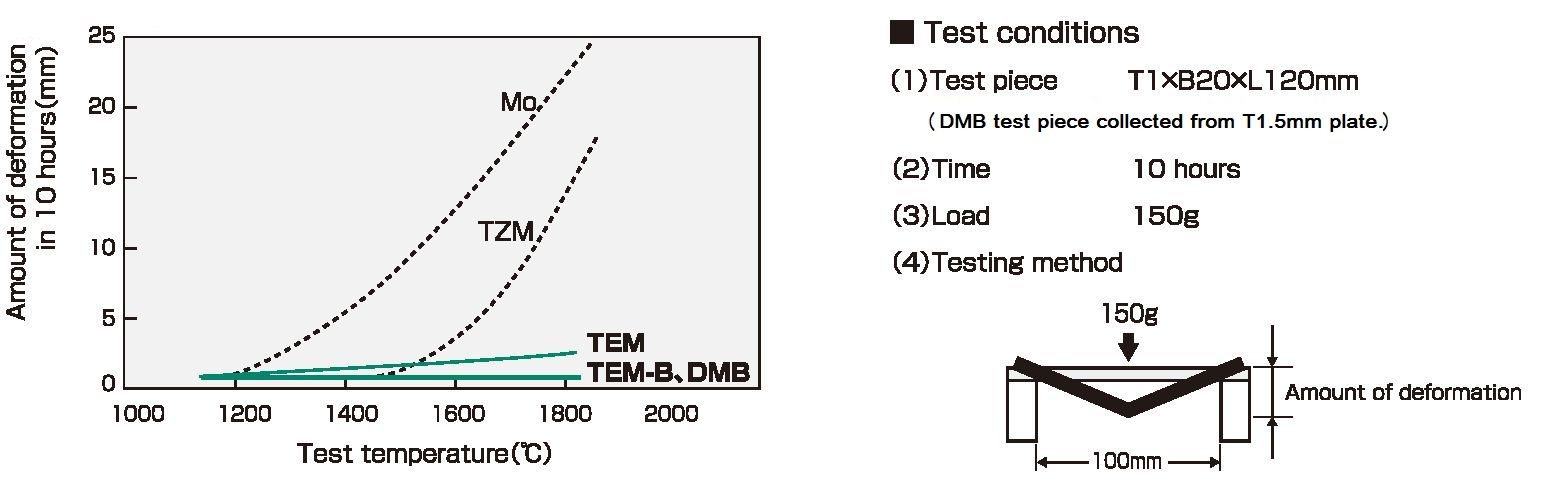

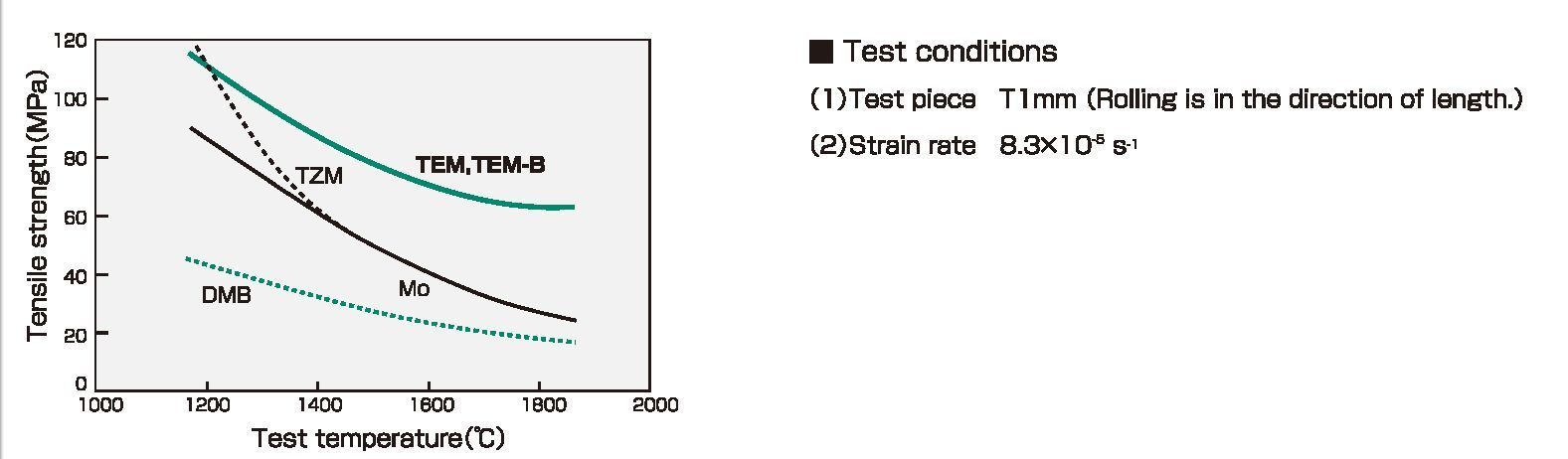

High-temperature deformation resistance of various kinds of molybdenum sheets / plates

High-temperature strength of various kinds of molybdenum sheets / plates after use at high temperature (1,800℃)

Appearance after 1,500℃×100h (in vacuum) use

- TT-TEM™ reflector

- Pure Molybdenum (MOP) reflector

- Tungsten technical information

- Molybdenum technical information