ホーム > HOME > Product Information > Diamond tool/ CBN tool > Basic information about Diamond/CBN tools > Formula to calculate cutting process

Formula to calculate cutting process

Calculating of turning

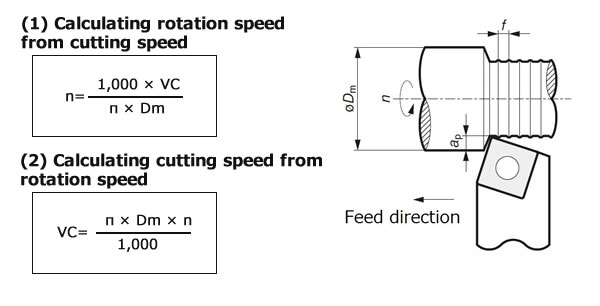

Calculating of turning [Calculating cutting speed and rotational speed]

(1) Calculating rotation speed from cutting speed

VC:Cutting speed(m/min)

Dm:Diameter of workpiece(mm)

n:Spindle speed(min-1)

(2) Calculating cutting speed from rotation speed

Dm:Diameter of workpiece(mm)

n:Spindle speed(min-1)

VC:Cutting speed(m/min)

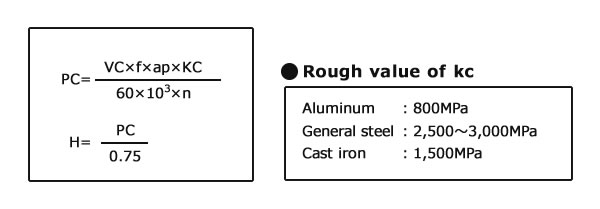

Calculating of turning [Calculating power requirement]

VC:Cutting speed(m/min)

f:Feed rate(mm/rev)

ap:Depth of cut(mm)

KC:Specific cutting force(MPa)

η:Machine efficiency(0.7~0.85)

PC:Net power requirement(kW)

H:Required horsepower(HP)

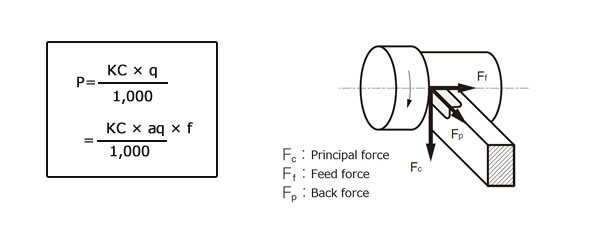

Calculating of turning [Calculating cutting force]

KC:Specific cutting force(MPa)

q:Chip area(mm2)

p:Cutting force(kN)

KC:Cutting force(MPa)

ap:Depth of cut(mm)

f:Feed rate(mm/rev)

p:Cutting force(kN)

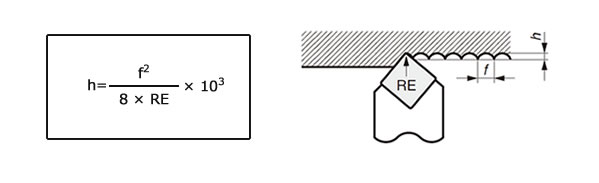

Calculating of turning [Calculating machined surface roughness]

f:Feed rate(mm/rev)

RE:Nose radius(mm)

h:Theoretical surface roughness(μm)

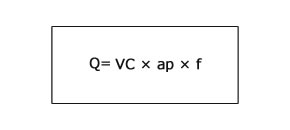

Calculating of turning [Calculating chips discharge amount]

VC:Cutting speed(m/min)

ap:Depth of cut(mm)

f:Feed rate(mm/rev)

Q:Chips discharge amount(cm3/min)

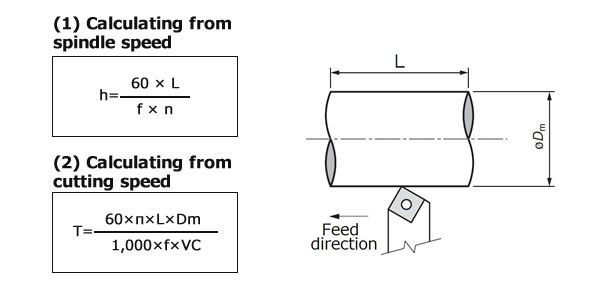

Calculating of turning [Calculating machining time (OD)]

(1) Calculating from spindle speed

L:Machining length(mm)

f:Feed rate(mm/rev)

n:Spindle speed(min-1)

T:Machining time(sec)

(2) Calculating from cutting speed

L:Machining length(mm)

f:Feed rate(mm/rev)

Dm:OD of work material(mm)

VC:Cutting speed(m/min)

T:Machining time(sec)

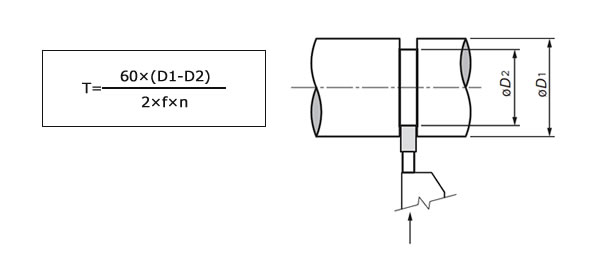

Calculating of turning [Calculating machining time (Grooving)]

f:Feed rate(mm/rev)

n:Spindle speed(min-1)

D1:Max. diameter of work material(mm)

D2:Min. diameter of work material(mm)

T:Machining time(sec)

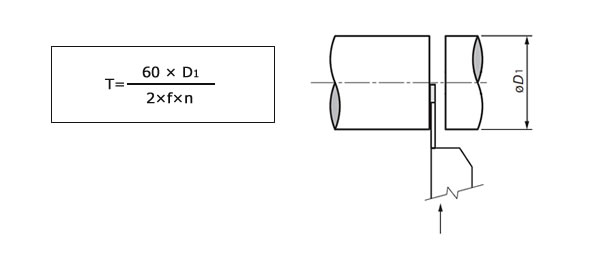

Calculating of turning [Calculating machining time (Cutting-off)]

f:Feed rate(mm/rev)

n:Spindle speed(min-1)

D1:Max. diameter of work material(mm)

T:Machining time(sec)

Milling calculation formulas

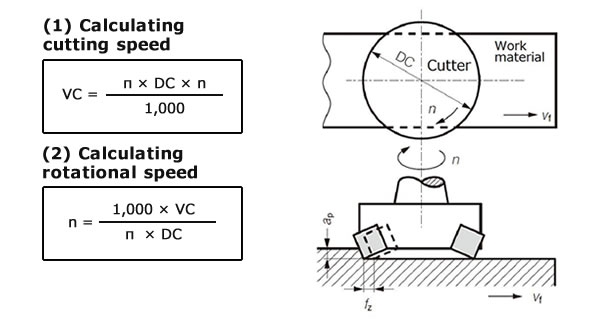

Milling calculation formulas [Calculating cutting speed]

(1) Calculating cutting speed

DC:Cutter diameter(mm)

n:Rotational speed(min-1)

VC:Cutting speed(m/min)

(2) Calculating rotational speed

VC:Cutting speed(m/min)

DC:Cutter diameter(mm)

n:Rotational speed(min-1)

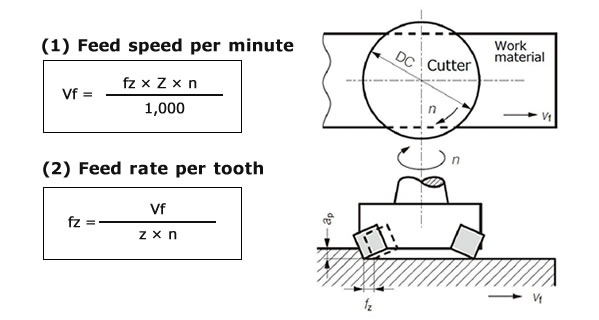

Milling calculation formulas [Calculating feed speed]

(1) Feed speed per minute

fz:Feed rate per tooth(mm/t)

Z:Number of teeth(pieces)

n:Rotational speed(min-1)

Vf:Feed speed per minute(m/min)

(2) Feed rate per tooth

Vf:Feed speed per minute(m/min)

Z:Number of teeth(pieces)

n:Rotational speed(min-1)

fz:Feed rate per tooth(mm/t)

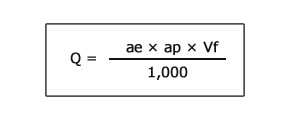

Milling calculation formulas [Calculating chip removal amount]

ae:Cutting width(mm)

Vf:Feed speed per minute(mm/min)

ap:Depth of cut(mm)

Q:Chip removal amount(cm3/min)

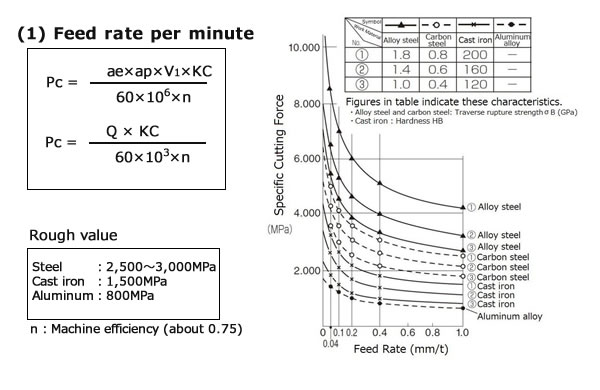

Milling calculation formulas [Calculating power requirement]

ae:Cutting width(mm)

apDepth of cut(mm)

KC:Specific cutting force(MPa)

vf:Table feed speed per minute(mm/min)

η:Machine efficiency(about 0.75)

Pc:Power requirement(kW)

Q:Chip removal amount(cm3/min)

KC:Specific cutting force(MPa)

η:Machine efficiency(about 0.75)

Pc:Power requirement(kW)

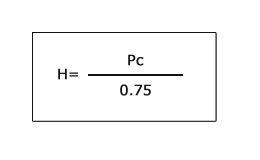

Milling calculation formulas [Calculating required horsepower]

PC:Power requirement(kw)

H:Power requirement(horsepower)

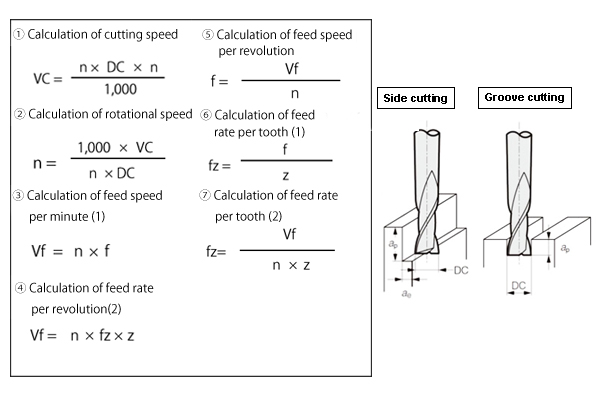

Endmilling calculation formulas

(1) Calculating cutting speed

DC:Endmill diameter(mm)

n:Spindle speed(min-1)

VC:Cutting speed(m/min)

(2) Calculating spindle speed

VC:Cutting speed(m/min)

DC:Endmill diameter(mm)

n:Spindle speed(min-1)

(3) Calculating feed rate per minute (1)

f:Feed rate per tooth(mm/rev)

n:Spindle speed(min-1)

Vf:Feed rate per minute(m/min)

(4) Calculating feed rate per minute (2)

Z:Number of teeth(pieces)

n:Spindle speed(min-1)

fz:Feed rate per tooth(mm/t)

Vf:Feed rate per minute(m/min)

(5) Calculating feed rate per revolution

n:Spindle speed(min-1)

Vf:Feed rate per minute(m/min)

f:Feed rate per tooth(mm/rev)

(6) Calculating feed rate per tooth (1)

f:Feed rate per revolution(mm/rev)

Z:Number of teeth(pieces)

fz:Feed rate per tooth(mm/t)

(7) Calculating feed rate per tooth (2)

Vf:Feed rate per minute(m/min)

n:Spindle speed(min-1)

Z:Number of teeth(pieces)

fz:Feed rate per tooth(mm/t)

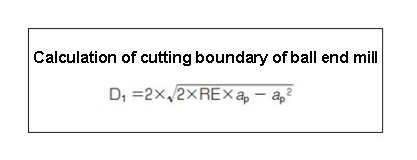

・Calculating notch width of ball endmill

RE:Ballnose radius(mm)

ap:Depth of cut(mm)

D1:Notch width(mm)

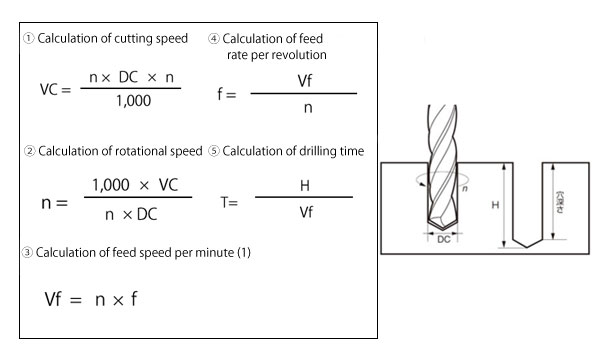

Drilling calculation formulas

(1) Calculating cutting speed

DC:Drill diameter(mm)

n:Spindle speed(min-1)

VC:Cutting speed(m/min)

(2) Calculating spindle speed

VC:Cutting speed(m/min)

DC:Drill diameter(mm)

n:Spindle speed(min-1)

(3) Calculating feed rate per minute (1)

f:Feed rate per tooth(mm/rev)

n:Spindle speed(min-1)

Vf:Feed rate per minute(m/min)

(4) Calculating feed rate per revolution

n:Spindle speed(min-1)

Vf:Feed rate per minute(m/min)

f:Feed rate per tooth(mm/rev)

(5) Calculation of cutting time

H:Drilling depth(mm)

Vf:Feed rate per minute(m/min)

T:Cutting time(min)

- Please feel free to contact us

-

-

- Inquiries by email

- For emailing form

-

- Inquiries by phone

- For sales office

-