What are diamond/CBN cutting tools?

What is cutting?

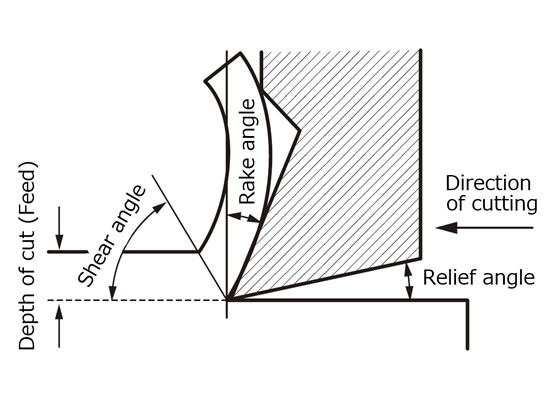

Metal cutting is a processing method that causes sliding inside a metal by shearing force accompanying compression and then separates the metal.

Cutting, feeding amount (speed) and cutting speed are three cutting conditions; other conditions are called operational conditions.

The larger the rake angle, the less the cutting resistance.

Increasing cutting speed reduces the cutting resistance.

Cooling oil cools the cutting edge and workpiece, suppressing softening caused by high temperature and deformation resulting from heat. It is also used to provide a lubrication effect between the cutting edge and chips, thus preventing welding.

Characteristics of material

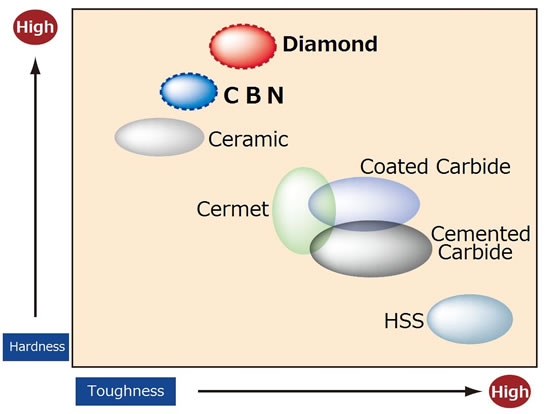

Diamond excels in "hardness" and "heat diffusibility" as a cutting tool material. CBN, with hardness akin to that of diamond diamond is mainly used for cutting ferrous metal thanks to its lower reactivity than diamond with ferrous metal. Both materials can be polished to form "sharp cutting edge."

Diamond/CBN cutting tools

Although various materials such as carbide and high-speed steels are used as cutting tools, diamond/CBN tools have excellent "hardness" and "diffusion of heat" compared with these materials.

Polished diamond/CBN tools can make "sharp cutting edge."

Diamond/CBN cutting tools with these characteristics provide superior precision, superior lifetime, and high performance for your work pieces.

| Diamond | Cemented Carbide | High Speed Steel | ||

|---|---|---|---|---|

| Single crystalline | Polycrystalline | |||

| ① High hardness | ◎ | ◎ | △ | × |

| ② Adequate toughness | × | △ | ○ | ◎ |

| ③ Good thermal diffusivity | ◎ | ○ | △ | △ |

| ④ Sharpness of cutting edge | ◎ | × | △ | ○ |

| ⑤ Affinity with ferrous metals | × | × | △ | △ |

| ⑥ Isotropy | × | ○ | ◎ | ◎ |

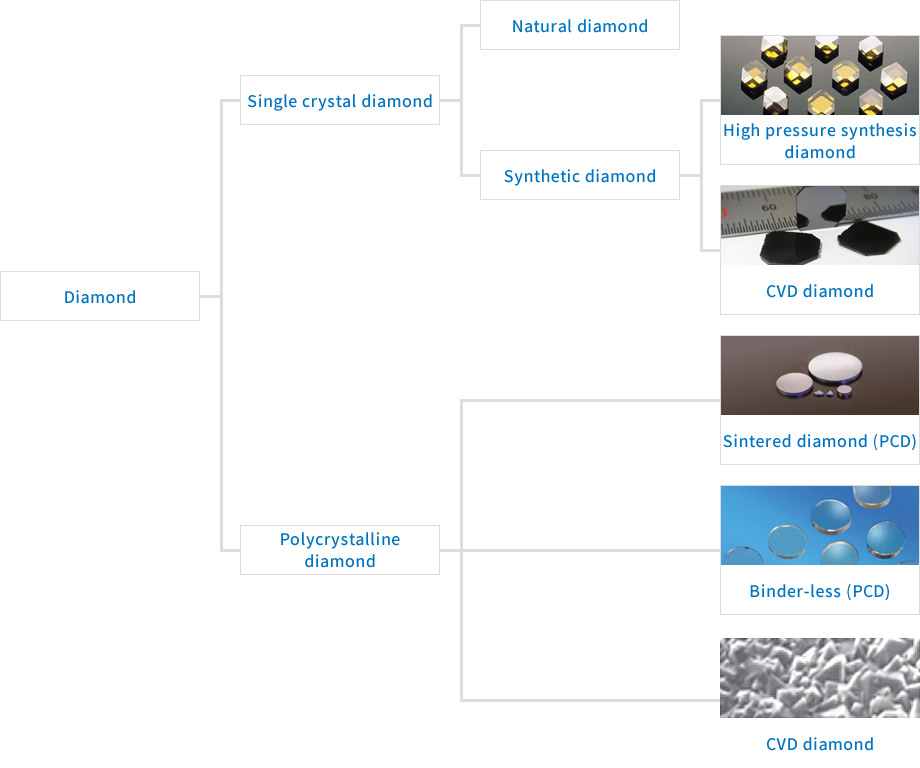

Types of Diamond

- Please feel free to contact us

-

-

- Inquiries by email

- For emailing form

-

- Inquiries by phone

- For sales office

-