search results

17件中/1-17件目を表示

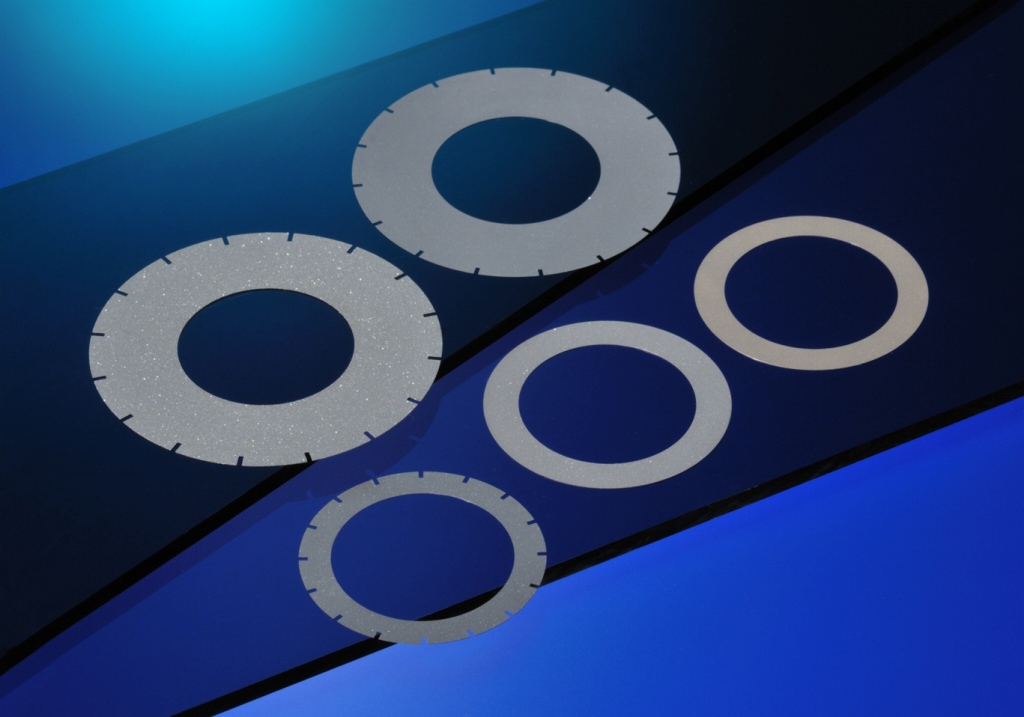

A vitrified bond wheel having high grain holding power. The high porosity structure and the characteristic grain layer shape realize low grinding resistance and create a new grinding region.

| Applications | Primary grinding of as deposition and as-sliced wafers, etc. |

|---|

This wheel demonstrates excellence in reducing damaged layers and strain layers during grinding of brittle materials such as reducing polishing of 300-mm silicon wafers and minimizing cracking of thin device wafers.

| Applications | Ultra-precision surface grinding of various semiconductor wafers |

|---|

Continuous grinding of single crystal SiC wafers that are difficult to grind with other wheels is now possible. Grinding can be performed at the same feed rate as for Si wafers and ultra-smooth surfaces can be produced.

| Applications | Ultra-precision surface grinding of various semiconductor wafers |

|---|

Brittle LT wafers used for SAW filters can be ground with low damage and high quality.

| Applications | Precision surface grinding of LT wafers |

|---|

A thin blade wheel of all-grain layer type realized by our original electroforming technology to enable high precision cutting and fine grooving accurately.

| Applications | Precision cutting and grooving of various materials |

|---|

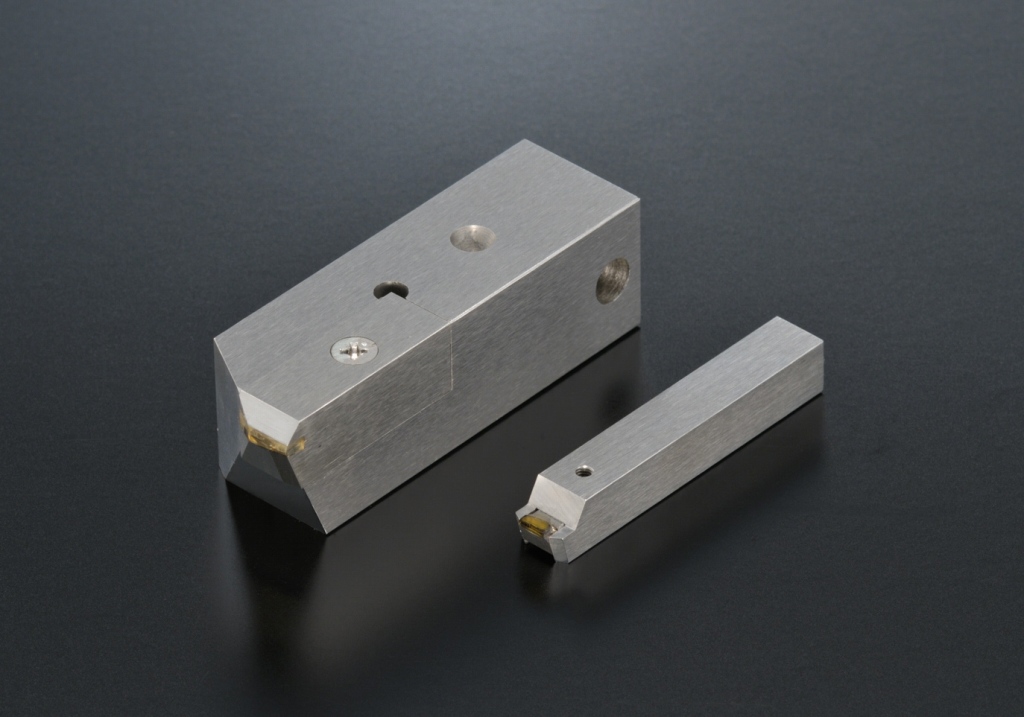

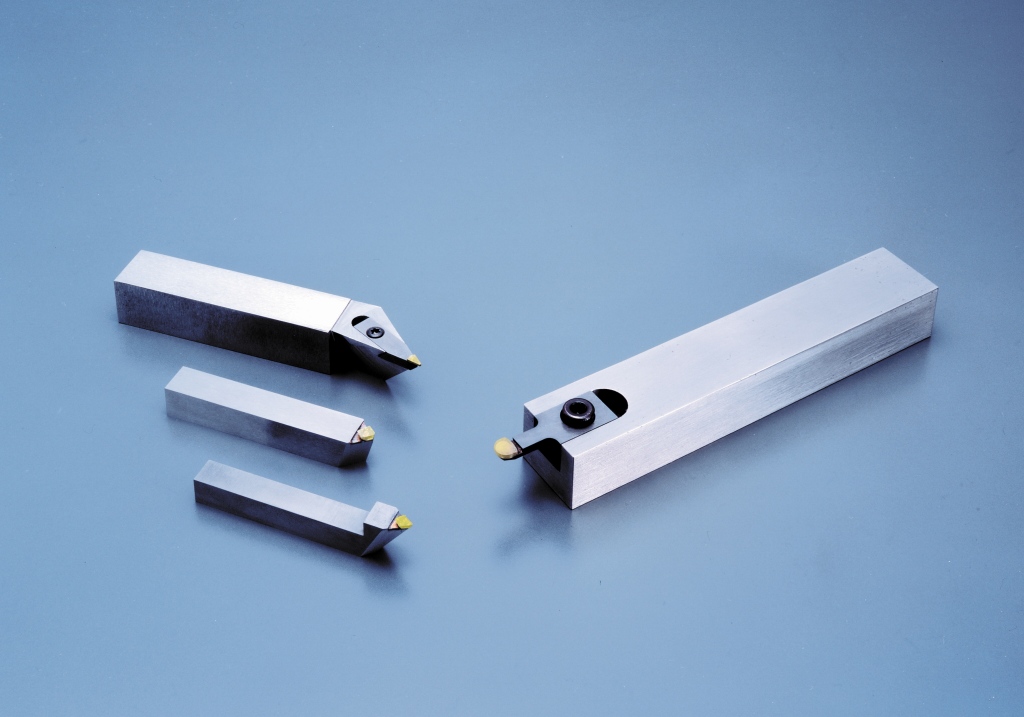

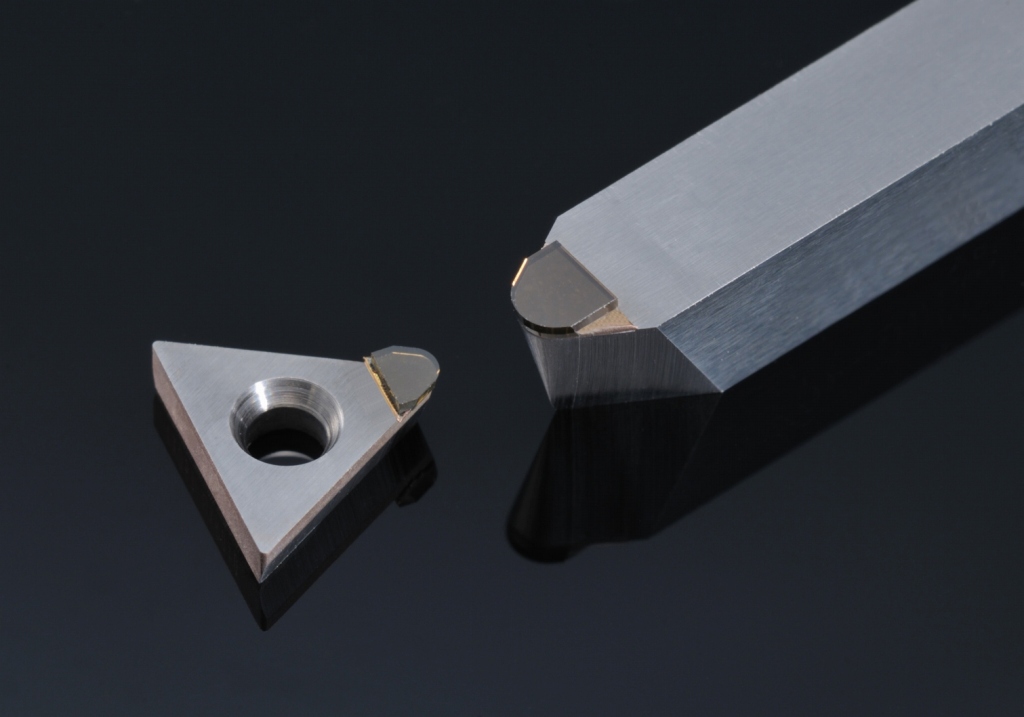

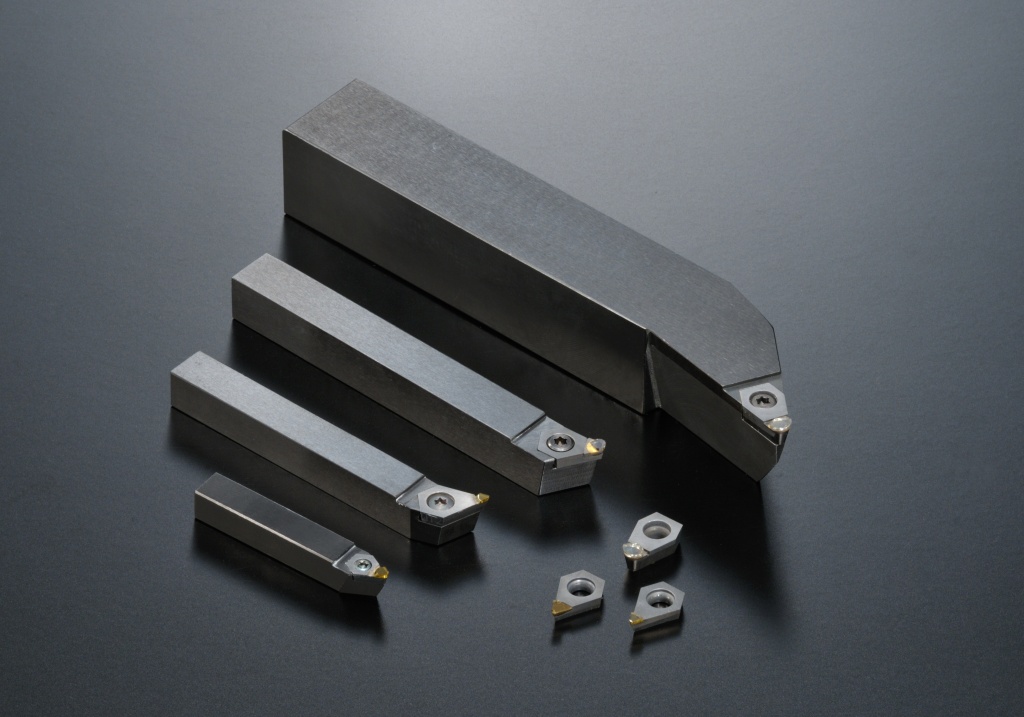

A lineup of cutting tools for various nano/micro-forming. The cutting edge polished accurately and measured carefully by our original technologies can machine workpieces in the order of nanometer to realize high precision micro-shape machining

| Applications |

|---|

This tool has a cutting edge with high precision profile within a wide working angle range to realize excellent shape machining. This tool exhibits excellent performance in ultra-precision machining of spherical and aspherical surfaces.

| Applications | Molds of pickup lenses for CD, DVD and Blu-ray, molds of lenses for digital cameras,, molds of camera lenses for cell phones, PC and tablets, infrared lenses, spherical/aspherical mirrors for laser/X-rays, various spherical and aspherical lenses, profile machining with ultra-precision machine |

|---|

A tool ideal for high efficiency and ultra-precision cutting of planes and cylinders. An ultra-precision cutting tool that significantly reduces or eliminates the time for running-in.

| Applications | Laser reflection mirrors, polygon mirrors, copier photosensitive drums, plane and cylindrical mirror finishing |

|---|

Ideal for ultra fine grooving of Fresnel lens, etc. The shape of cutting edge tips is guaranteed in the order of submicron.

| Applications | Molds of LCD light guide plates, Fresnel lens molds, optical sheet molds, various grating molds, other fine grooving |

|---|

Our original minute cutting edge treatment* has been applied to the single crystal diamond cutting edge to improve the tool life. *Patented.

| Applications | Infrared sensor lenses, night vision camera lenses, germanium lenses, silicon lenses, calcium fluoride lenses, cobalt-less carbide molds |

|---|

An ultra precision cutting tool that employs "SUMIDIA Binderless" on the UPC cutting edge. Long life in mirror-cutting of cemented carbide and machining of fine shapes is ensured. SUMIDIA is the registered trademark of Sumitomo Electric Industries, Ltd.

| Applications | Machining of cemented carbide glass lens molds, prism sheet large roll molds, light guide plate large molds, glass lenses and other high hardness and brittle materials |

|---|

Our original precision machining technology has realized a high quality cutting edge. No chips will be fused or deposited on the rake face to keep producing high quality surfaces even during continuous operations.

| Applications | Non-ferrous metal parts such as automotive parts (pistons, aluminum wheels, compressors, commutators), plastic lenses, resin molded parts, HDD parts and aluminum die-cast parts |

|---|

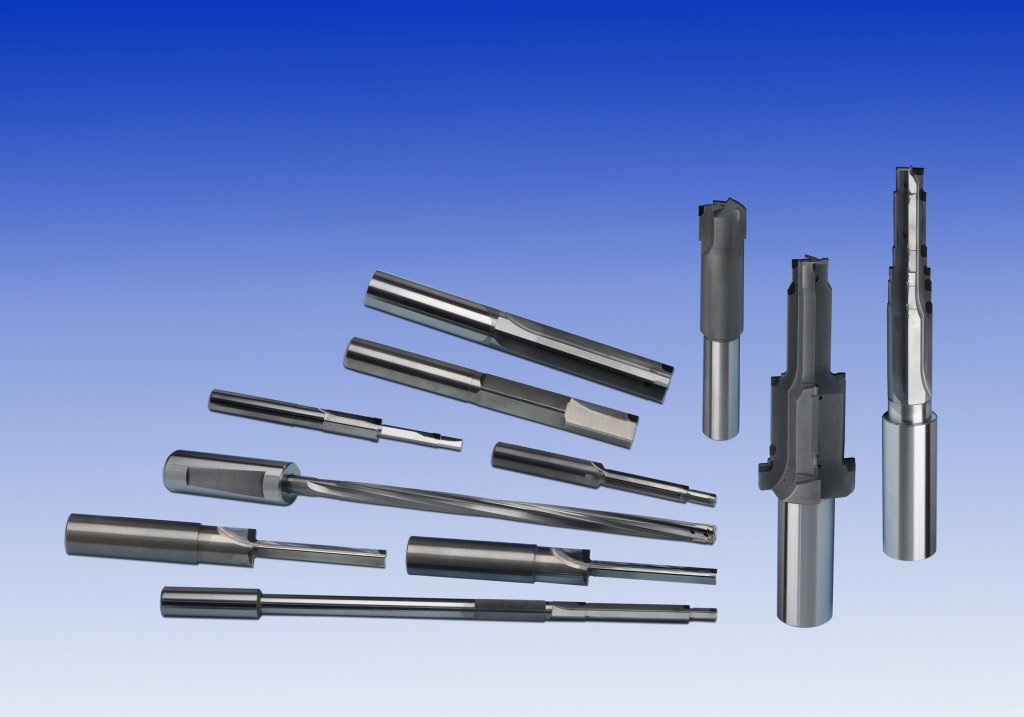

A rotating tool that employs a diamond sintered body (PCD) for the cutting edge. This is used for machining of not only non-ferrous metals represented by aluminum, but also of non-metals such as resin and wood. Various tools including reamers, drill reamers and end mills have been developed to meet various customer needs.

| Applications | Non-ferrous metal parts such as automotive aluminum parts, engine valve guide holes, resin molded parts, aluminum die-cast alloys and spectacle lenses |

|---|

A reamer and drill reamer that employ a diamond sintered body (PCD) for the cutting edge. Various types of tools are available according to your requirements of workpiece shapes, machining accuracy and tact time.

| Applications | Non-ferrous metal parts such as automotive aluminum parts, engine valve guide holes, resin molded parts, aluminum die-cast alloys and spectacle lenses |

|---|

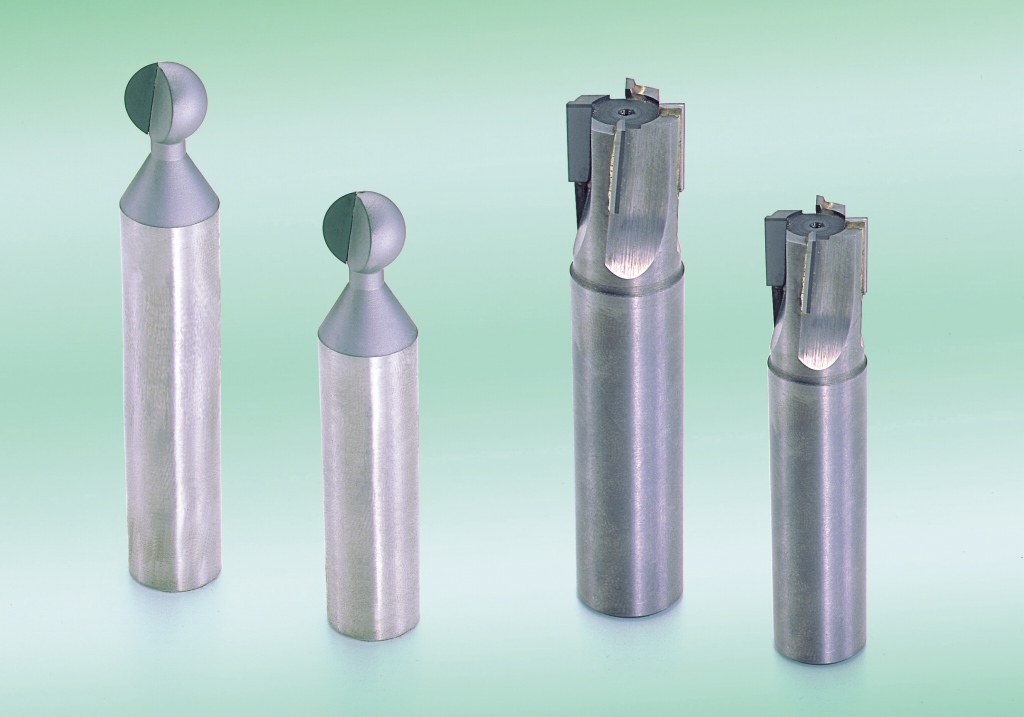

An end mill that employs a diamond sintered body (PCD) for the cutting edge. This tool lasts 10 times or more longer than carbide tools to provide consistent cutting performance.

| Applications | Non-ferrous metal parts such as automotive aluminum parts, engine valve guide holes, resin molded parts, aluminum die-cast alloys and spectacle lenses |

|---|

A diamond sintered body (PCD) is used for the cutting edge. Not only the holder-integrated body type, but also the cutting edge replacement type is available.

| Applications | Non-ferrous metal parts such as automotive aluminum parts, engine valve guide holes, resin molded parts, aluminum die-cast alloys and spectacle lenses |

|---|

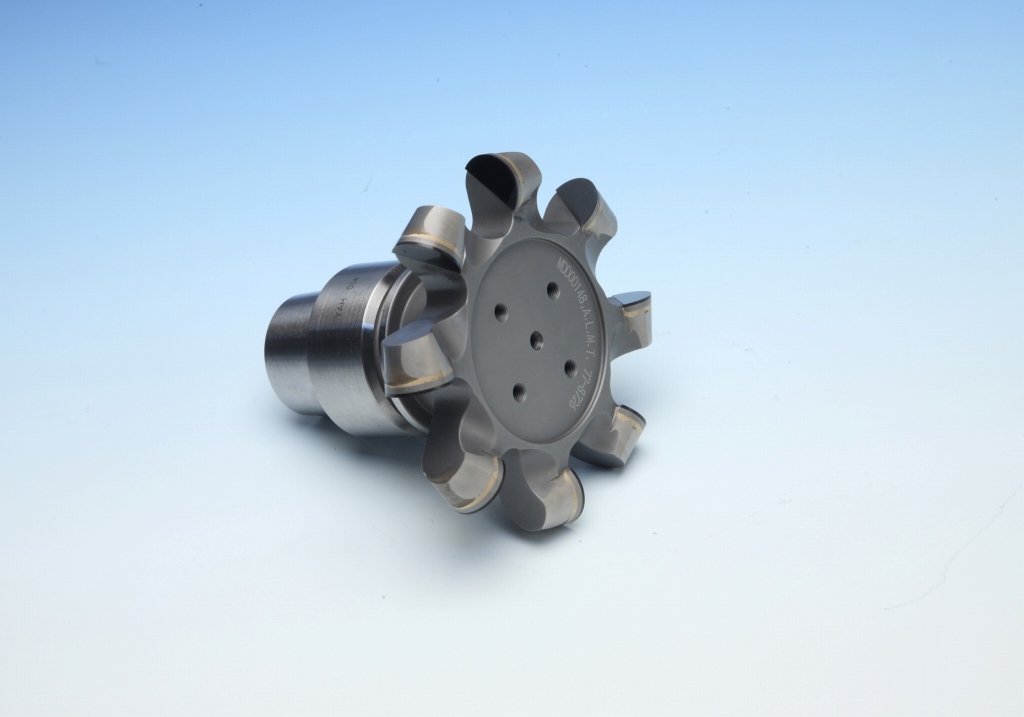

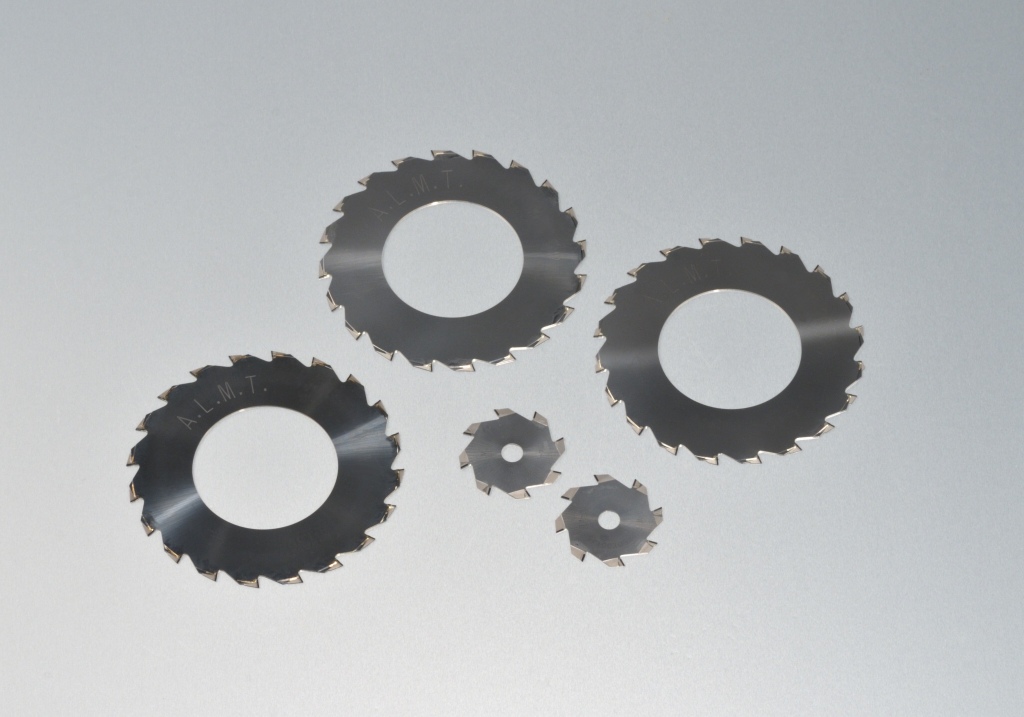

A PCD rotating tool for cutting and grooving of resin and non-ferrous materials. This tool offers long life, high quality and high efficiency machining over carbide/coated tools.

| Applications | Cutting and grooving of electronic materials, composite materials, etc. |

|---|

- Please contact below for Inquiries about diamond tools/ CBN tools