ホーム > HOME > Product Information > Diamond tool/ CBN tool > Basic information about Diamond/CBN tools > What is a diamond drawing dies?

What is a diamond drawing dies?

What is a diamond drawing dies?

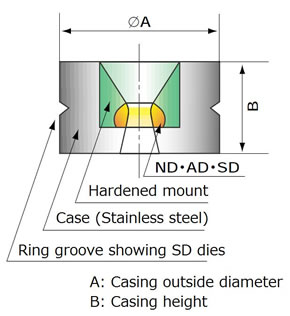

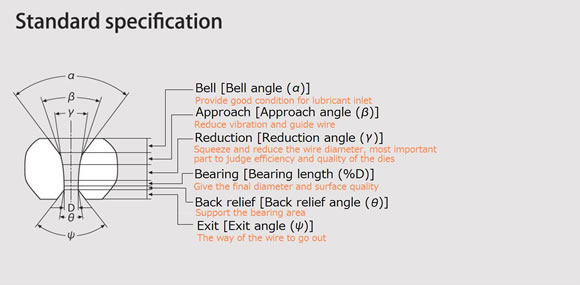

To make desired smaller wire diameter by a tool with conical hole is called "wire drawing " or "wire drawing process". The hole of the tool has different diameter each side, its entrance is wide and its exit is small - the tool is "die"."Diamond dies" has with diamond for superior precision and longevity.We suggest appropriate diamond type and die shape for application.

Structure and role of diamond drawing dies

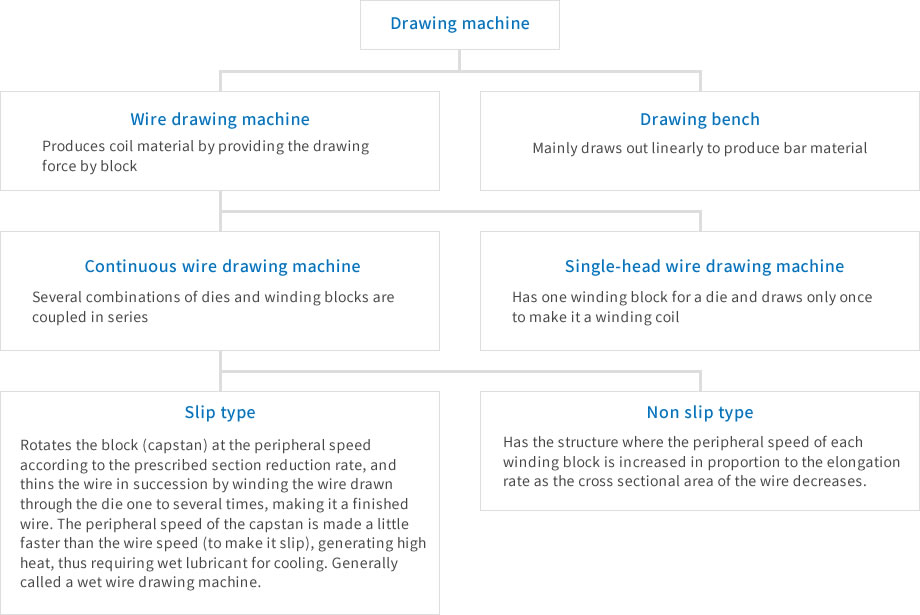

Wire drawing machine types

Types of lubricant

Lubricants are necessary to reduce friction between the die and wire material when drawing, preventing wear of the die, and seizures and scratches on the wire surface.

Types of lubricant: dry lubricant, wet lubricant for wire material, oil lubricant, etc.

Lubricants can be used properly according to wire material, processing method, and desired finish state.

Performance

- Dry lubricant (powder)

- The basic ingredients are inorganic substances such as metal soap and lime; sulfur, molybdenum disulfide and the like are blended as an extreme pressure additive for improving seizure resistance. Mainly used for drawing steel wire.

- Oil lubricant (grease)

- Based on mineral oil, and animal and vegetable oils, extreme pressure additives are added.

Suitable for wire of metallic luster such as aluminum.

- Wet lubricant (liquid)

- Wet lubricants consist of animal and vegetable oils, mineral oil, and additives.

Surfactant is used to disperse and emulsify it in water. Suitable for drawing wire of metallic luster such as aluminum and thin wire.

- Please feel free to contact us

-

-

- Inquiries by email

- For emailing form

-

- Inquiries by phone

- For sales office

-