ホーム > HOME > Product Information > Diamond tool/ CBN tool > Basic information about Diamond/CBN tools > Type and characteristics of Diamond/CBN wheels

Type and characteristics of Diamond/CBN wheels

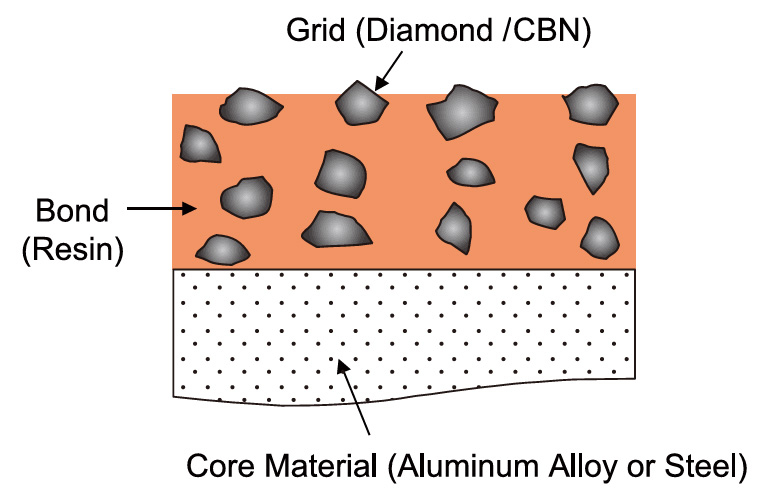

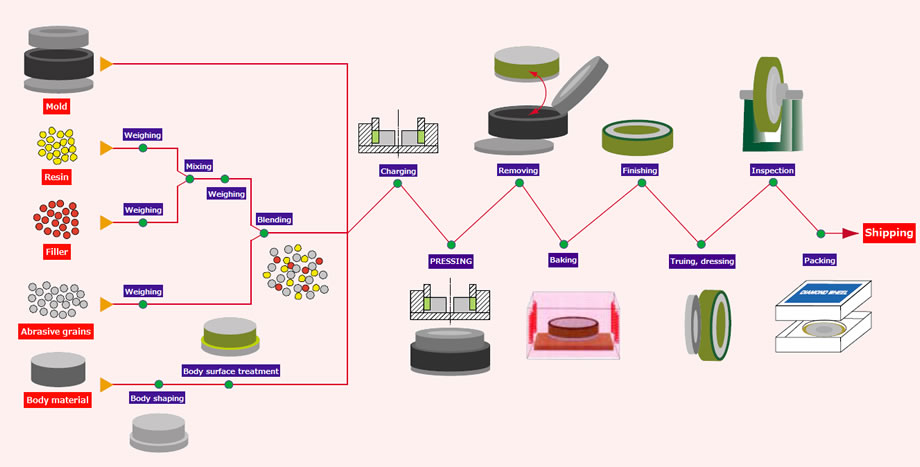

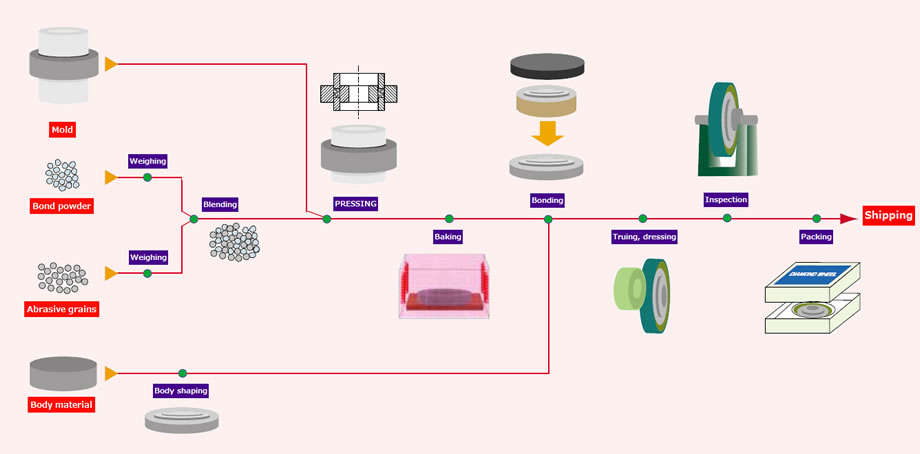

Resin bond wheel

- Structure

- Diamond/CBN abrasive grains, resin powder and filler are mixed and sintered in production.

Phenol resin is generally used, but polyimide resin, excellent in heat resistance, is also coming into wide use. - Characteristics

-

- Because the abrasive grains are held by a resin with low elastic modulus (Young's modulus), good surface roughness can be obtained.

- Bond can be retracted well (excellent autogenous blade property) enough to last sharpness long.

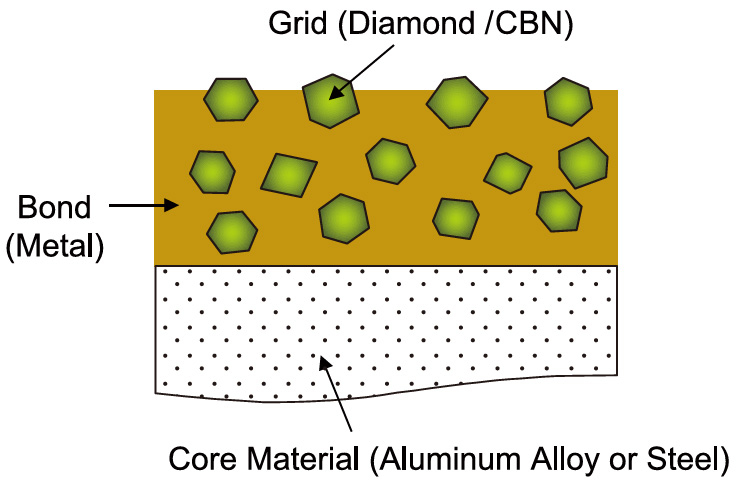

Metal bond wheel

- Structure

- Diamond/CBN abrasive grains, metal powder and filler are mixed and sintered in production.

The metal powder used includes copper, tin, iron, cobalt, and tungsten. - Characteristics

-

- High wear resistance and high abrasive grain holding power allow extended wheel lifetime.

- Good sharpness is demonstrated with materials processed in brittle mode such as glass and ferrite.

- High thermal conductivity reduces thermal degradation of abrasive grains and bond caused by heat generated during grinding.

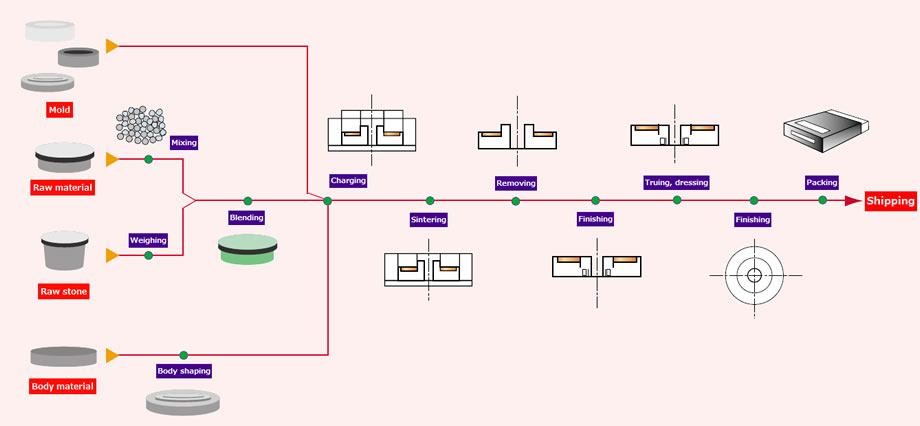

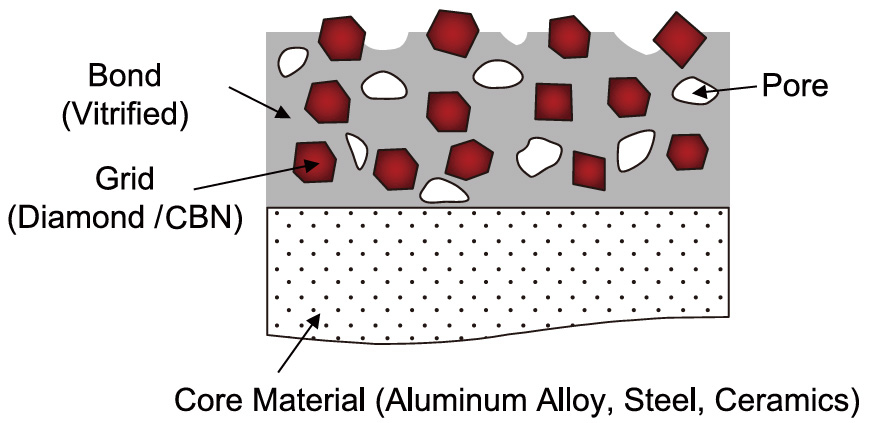

Vitrified bond wheel

- Structure

- Structure is stomatal where diamond/CBN abrasive grains, ceramic powder mainly composed of glass, and fillers were mixed and sintered.

It is a bond that has been used from the beginning as a bond for general whetstones (conventional whetstones). - Characteristics

-

- Good sharpness because of the stomatal structure.

- Excellent properties of truing/dressing make it suitable for high efficiency machining.

- Because CBN abrasive grains can be molded with a rotary dresser, mass production can be used to grind all parts.

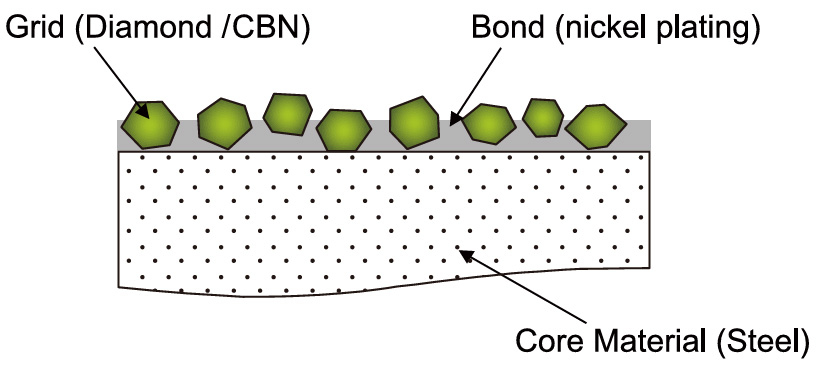

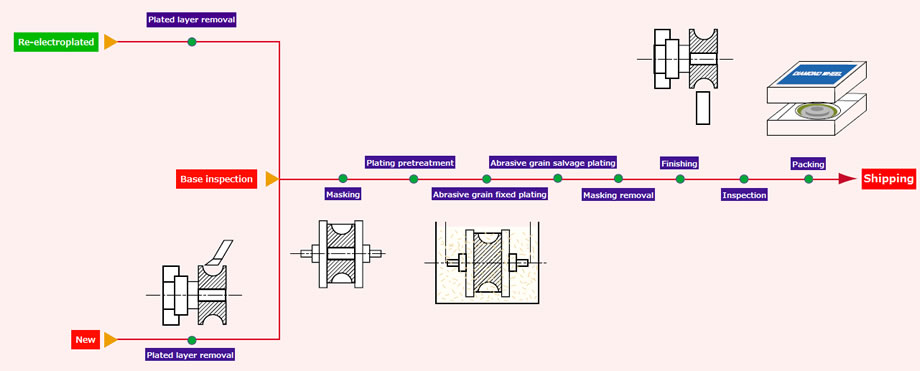

Electroplated wheel

- Structure

- This structure holds only a single layer of diamond/CBN abrasive grains on the surface of the base metal precisely machined by nickel plating.

- Characteristics

-

- Large abrasive grain protrusion allows good chip discharge properties, sustaining good sharpness.

- Complex shapes of total parts can be manufactured relatively easily, and the base metal can be reused.

- Please feel free to contact us

-

-

- Inquiries by email

- For emailing form

-

- Inquiries by phone

- For sales office

-