Truing & dressing

Truing and dressing are very important to effectively use diamond/CBN wheels so that they fully demonstrate their excellent performance. No matter how precisely the wheel is attached to the machine, runout occurs at the initial stage after installation.

Also, the abrasive grain layer deteriorates in accuracy and sharpness decreases due to wear in the grinding process. To maintain good sharpness, truing and dressing with a method and condition suitable for the grinding wheel is required.

-

Immediately after installing the equipment, correcting circumferential runout is required.

Crushing and falling off of abrasive grains reduce sharpness.

-

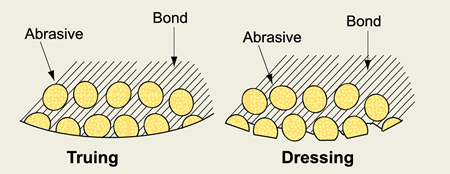

Eliminate irregularities on the abrasive surface, as well as runout, and create perfect circle (truing)

-

Retract bond and project the cutting edge (dressing)

- 【Truing】

- To mold when the grinding surface sways while the wheel is rotating or when the shape has collapsed.

- 【Dressing】

- To remove unnecessary bond and chips on the surface, letting abrasive grains project.

To see the whole table, scroll sideways..

| Abrasive grain size | #60~#140 | #170~#270 | #325~#500 | #600~ |

|---|---|---|---|---|

| B | C80K | WA120 I | GC300H | GC500H |

| M/V | C80K | C80K | WA120 I | GC300H |

To see the whole table, scroll sideways..

| Abrasive grain size | #60~#120 | #140~#170 | #200~#270 | #325~#500 | #600~#1000 | #1500~ |

|---|---|---|---|---|---|---|

| B | WA200G | WA200G | GSC00H | GC500H | GC1000G | GC1500F |

| M/V | WA120 I | WA200G | WA300G | WA300F | WA500F | GC8001F |

To see the whole table, scroll sideways..

| ◎:Best ○:Good △:Possible Blank:Not suitable | Truing | Dressing | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diamond Wheel | CBN Wheel | Diamond Wheel | CBN Wheel | |||||||||||

| Truing method and tool | B | M | V | B | M | V | B | M | V | B | M | V | ||

| Diamond tool method | Rotary | Rotary dresser | ◎ | ○ | ◎ | ◎ | ○ | ◎ | ◎ | ◎ | ○ | |||

| Metal wheel | ○ | ◎ | ○ | ◎ | ||||||||||

| Electroplated arbor dresser | ○ | ◎ | ○ | ◎ | ||||||||||

| Stationary | Single stone dresser | |||||||||||||

| Multi-stone dresser | ◎ | ◎ | ||||||||||||

| Impregnated dresser | ◎ | ◎ | ||||||||||||

| High precision block dresser | ○ | ○ | ○ | ○ | ||||||||||

| Electroplated block dresser | ○ | ○ | ○ | ○ | ||||||||||

| Conventional grinding wheel method | Rotary | Block grinding | ○ | ○ | ○ | ○ | ○ | ○ | ◎ | ◎ | ○ | ◎ | ◎ | ○ |

| Brake control | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ○ | ○ | ○ | ◎ | ◎ | ○ | ||

| Cup wheel drive | ○ | ○ | ○ | ○ | ○ | ○ | ◎ | ◎ | ○ | ◎ | ◎ | ○ | ||

| Stationary | Stick | ◎ | ○ | △ | ◎ | ○ | △ | ○ | ◎ | ○ | ◎ | ◎ | ○ | |

| Mild steel method | Rotary | Mild steel roll | ○ | △ | △ | ○ | △ | △ | ○ | ◎ | △ | ○ | ◎ | △ |

| Stationary | Mild steel block | ◎ | △ | △ | ○ | △ | △ | ○ | ◎ | △ | ○ | ◎ | △ | |

| Crushing method | Crushing roll | ○ | ◎ | ○ | ◎ | |||||||||

| Loose abrasive grain method | Abrasive grain lapping | ○ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ | △ | △ | |

| Abrasive grain blasting | △ | ○ | △ | ○ | △ | △ | △ | △ | △ | △ | ||||

| Abrasive grain sludge pouring | ○ | ○ | △ | ○ | ○ | △ | ||||||||

| Electric discharge method | Electrode | ◎ | ◎ | ◎ | ◎ | |||||||||

- Please feel free to contact us

-

-

- Inquiries by email

- For emailing form

-

- Inquiries by phone

- For sales office

-