Various grinding methods

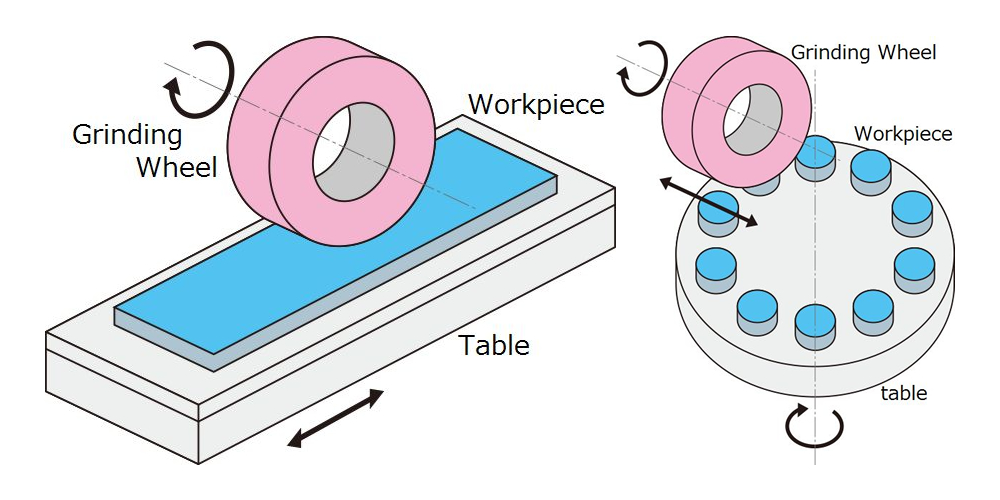

Surface grinding

Surface grinding is generally called Heiken or Hiraken, which uses either a vertical axis grinding machine or a horizontal axis grinding machine, with a square table or a circular table, and a straight type wheel or a cup type wheel.

The workpiece is fixed on a table and the wheel is rotated at high speed to perform grinding. The double-ended type is equipped with wheels above and below to perform grinding the workpiece in between. Surface grinding is the most common grinding method and is used in a wide range of fields.

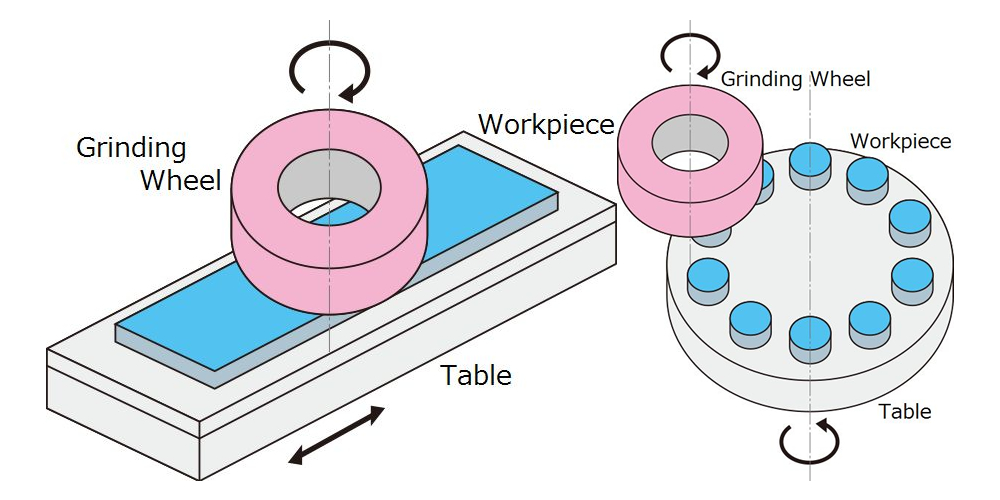

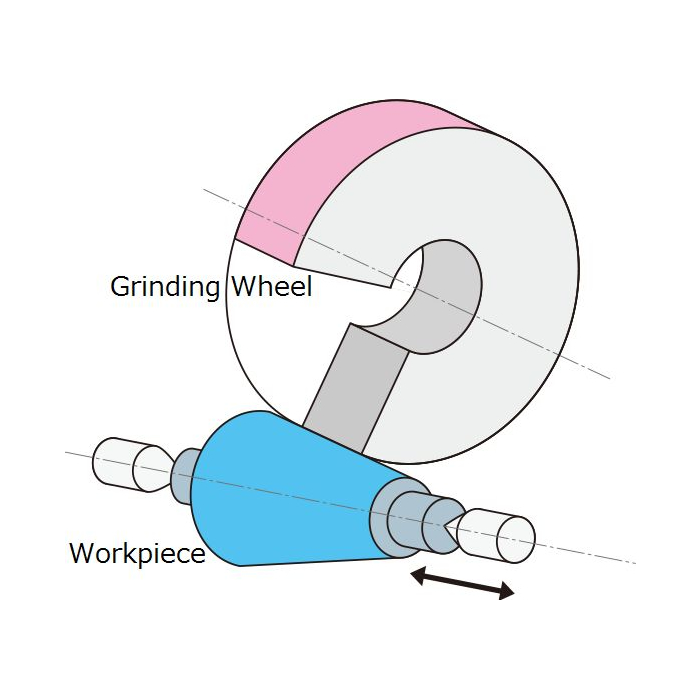

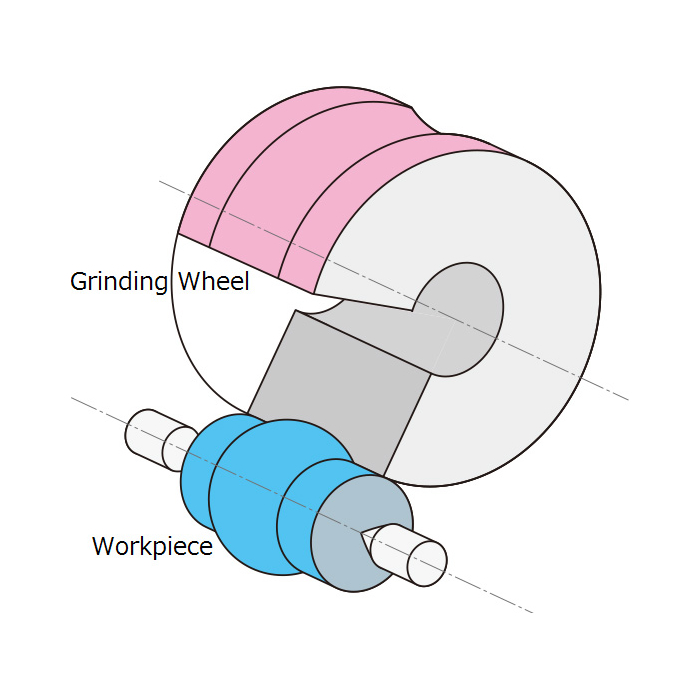

Cylindrical grinding

Cylindrical grinding is often called Enken, using either a cylindrical grinding machine or a universal grinding machine.

Both the cylindrical workpiece and the wheel are rotated and the outer periphery of the workpiece is machined.

The various grinding methods include straight cylindrical, taper, end face, and total shape grinding.

Similar to surface grinding, it is a general grinding method in wide use.

- Straight

- Taper

- Total shape

- Angular

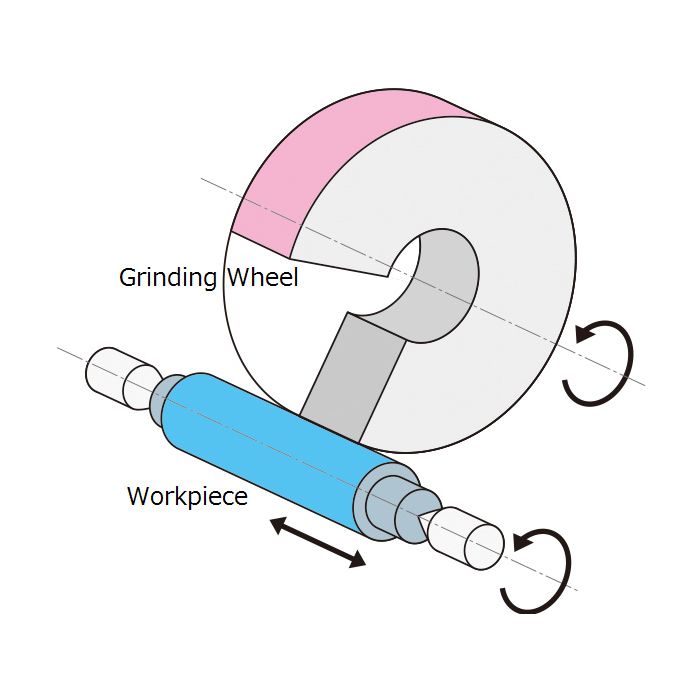

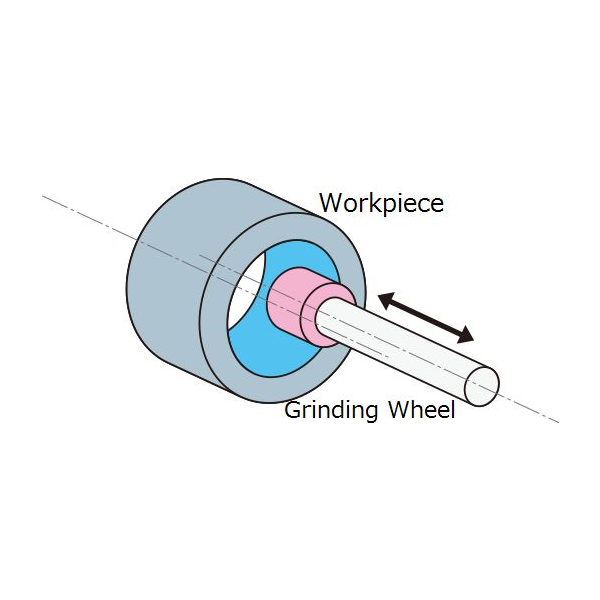

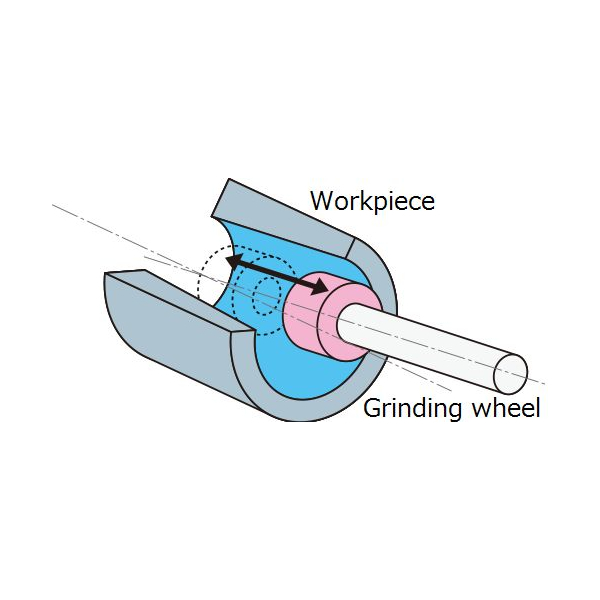

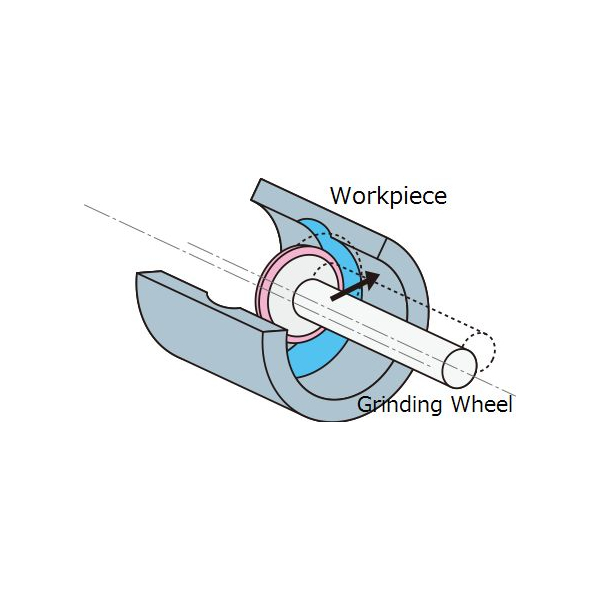

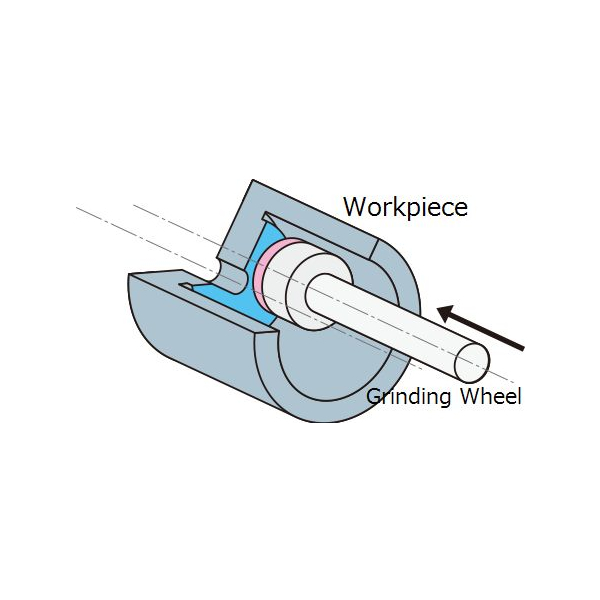

Internal grinding

Internal grinding is also called Naiken, using an internal grinding machine or a cylindrical grinding machine, or internal grinding equipment attached to a universal grinding machine.

The workpiece is fixed and the inner surface of the workpiece is machined with the rotating axle wheel. Grinding may sometimes be performed by rotating the workpiece. Similar to the cylindrical grinding, the grinding method includes taper and end face grinding.

- Internal grinding

- Taper

- Total shape

- End face

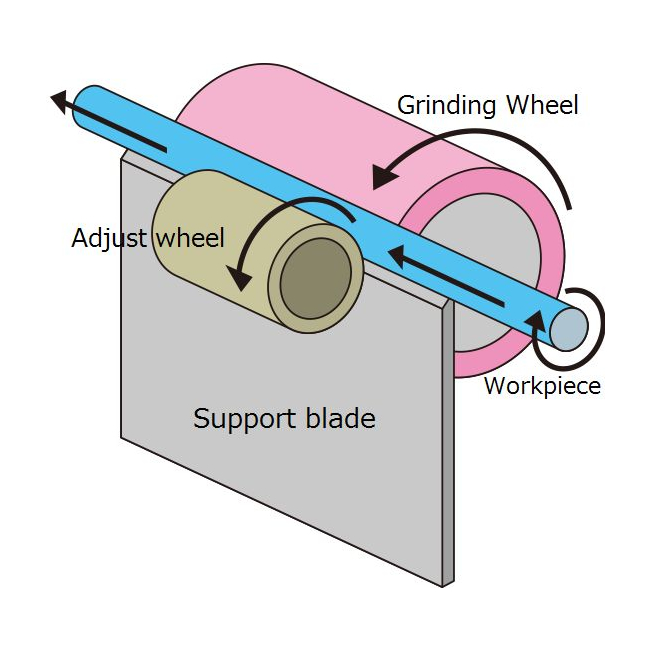

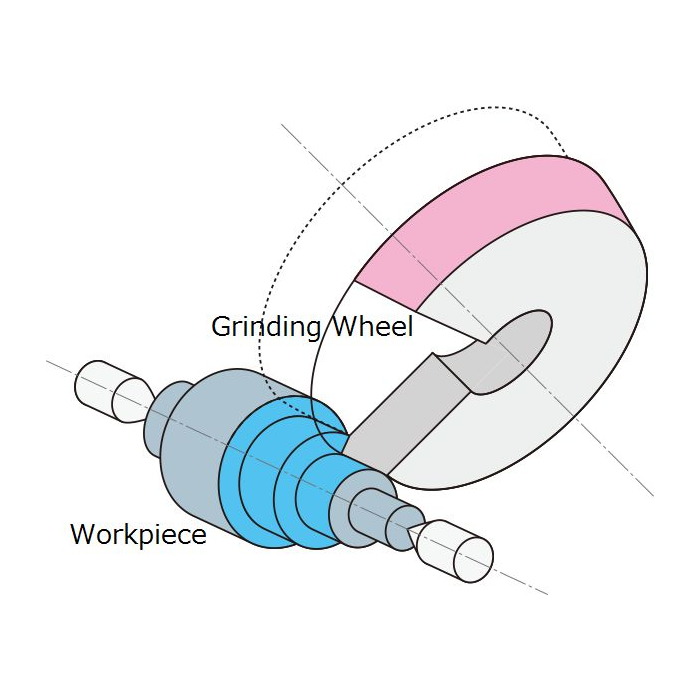

Centerless grinding

Centerless grinding is also called Shinnashi grinding, and processes the outer periphery of a cylindrical workpiece using a centerless grinding machine. A workpiece is supported between a fixed blade and a rotating adjusting wheel and a grinding wheel. The rotation and feed of the workpiece are then adjusted by rotation of the adjusting wheel to grind the outer circumference of the workpiece. Centerless grinding requires neither a center hole in the workpiece nor the workpiece’s installation on and removal from the grinding machine. These advantages make it suitable for mass production.

Contour grinding

Contour grinding is also called Narai grinding, a process that machines a workpiece into an arbitrary shape using a profile grinding machine, etc.

Gear grinding

Gear grinding is also called Haken, a process of shaping teeth such as gears using a gear grinding machine. General whetstones are mainly used, which are molded with the dresser (rotary dresser) using diamond abrasive grains.

Thread grinding

Thread grinding is a process of forming the thread using a teeth thread grinding machine.

- Please feel free to contact us

-

-

- Inquiries by email

- For emailing form

-

- Inquiries by phone

- For sales office

-