ホーム > HOME > Product Information > Diamond tool/ CBN tool > Basic information about Diamond/CBN tools > Troubleshooting of grinding

Troubleshooting of grinding

Resin/metal/vitrified bond wheels

To see the whole table, scroll sideways..

| Symptom | Possible Cause | Corrective Action |

|---|---|---|

| Poor surface roughness | Coarse abrasive grains | Reduce the grain size. |

| Wheel run-out | Check run-out and conduct truing/dressing. | |

| Machine vibration | Check wheel run-out and balance. | |

| Insufficient dressing amount | Increase the dressing amount and conduct dressing regularly. | |

| Supply amount and deterioration of grinding fluid | Increase the supply amount. Check grinding fluid for deterioration and replace fluid or filter. |

|

| Grinding burn | Insufficient dressing amount | Increase the dressing amount and conduct dressing regularly. |

| Inadequate grinding conditions | Reduce the wheel depth of cut and infeed speed. Reduce the wheel peripheral speed. |

|

| Insufficient supply of grinding fluid | Increase the supply amount or the supply pressure. Check the supply point. |

|

| Inadequate wheel specifications | Change the wheel specifications. ・Make the grain size larger. ・Lower the concentration. |

|

| Check the wheel surface. If dulled largely, soften the bond. | ||

| Feed mark | Wheel run-out | Check run-out and conduct truing/dressing. |

| Machine vibration | Check wheel run-out and balance. | |

| Inadequate wheel specifications | Check the wheel surface and change the grain size/bond. ・If the surface is dulled largely → Make the grain size larger. ・If the surface is shedded largely → Make the bond harder. |

Electroplated wheel

To see the whole table, scroll sideways..

| Symptom | Possible Cause | Corrective Action |

|---|---|---|

| Poor surface roughness | Coarse abrasive grains | Reduce the grain size. |

| Wheel run-out | Re-mount the wheel and adjust its run-out. | |

| Machine vibration | Re-mount the wheel and adjust its run-out. | |

| Inadequate grinding conditions | Increase the wheel peripheral speed. Extend the spark-out time. | |

| Supply amount and deterioration of grinding fluid | Increase the supply amount. Check grinding fluid for deterioration and replace fluid or filter. |

|

| Grinding burn | Inadequate grinding conditions | Reduce the wheel depth of cut and infeed speed. |

| Inadequate wheel specifications | Make the grain size larger. | |

| Insufficient supply of grinding fluid | Increase the supply amount or the supply pressure. Check the supply point. |

|

| Feed mark | Wheel run-out | Re-mount the wheel and adjust its run-out. |

| Machine vibration | Check wheel run-out and balance. |

Main abrasive surface conditions when trouble occurred

To see the whole table, scroll sideways..

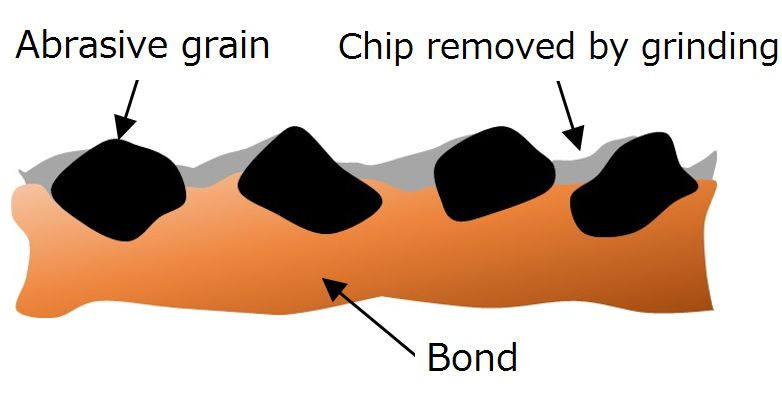

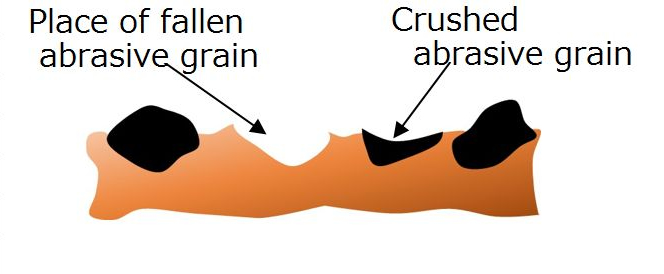

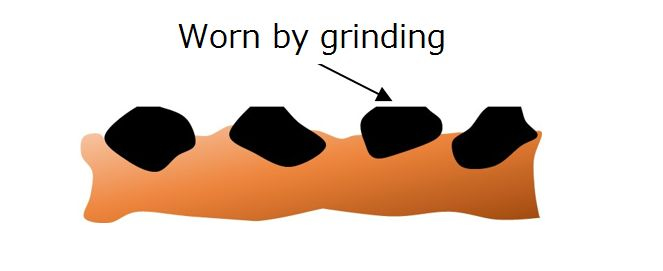

| Wheel Surface Condition | Schematic of Wheel Surface Conditions | |

|---|---|---|

| Loading | Surface loaded with chips to cover projection of abrasive grains or chips adhering to the cutting edge. |

|

| Shedding | Abrasive grains dropped out of bond due to fracture or falling. |

|

| Dulling | Sharp cutting edge worn and flattened to become dull. |

|

- Please feel free to contact us

-

-

- Inquiries by email

- For emailing form

-

- Inquiries by phone

- For sales office

-